Atulkumar S. Patil1* , Vishnu D. Wakchaure2

, Vishnu D. Wakchaure2 and Uddhav M. Shirsat3

and Uddhav M. Shirsat3

1AVCOE, Sangamner, Ahmednagar and Asst. Prof., KKWIEER, Nashik, Savitribai Phule Pune University, Pune, MS, India.

2AVCOE, Sangamner, Ahmednagar, Savitribai Phule Pune University, Pune, MS, India.

3Bhivrabai Sawant COER, Pune, Savitribai Phule Pune University, Pune, MS, India.

Corresponding Author E-mail: asplecturer@gmail.com

DOI : http://dx.doi.org/10.13005/msri/190204

Article Publishing History

Article Received on : 24 Jul 22

Article Accepted on : 16 Aug 2022

Article Published : 23 Aug 2022

Plagiarism Check: Yes

Reviewed by: Dr. Alemayehu Getahun Second Review by: Dr. Shashank Pathak

Second Review by: Dr. Shashank Pathak Final Approval by: Dr. Santanu Das

Final Approval by: Dr. Santanu Das

Article Metrics

ABSTRACT:

This study investigates the effect of various fiber laser process parameters on texture diameter, depth and surface roughness of circular shaped textures fabricated on the commercially cast iron piston ring segments. Piston ring segments with hardness 410 HV, Young’s Modulus of 250 Gpa and surface roughness of 0.482 µm were used for the experimentation. The fiber laser system (Marko Laser, Germany), was used for the fabrication of textures on the cast iron segments having specifications like power of 20W, wavelength of 1062nm, maximum frequency 200KHz, maximum speed range of 15000 mm/s. The laser frequency, power, speed and number of loops are the input parameters which were varied to find its effect on the texture dimensions. The approximate target values to be achieved for circular texture dimensions are texture diameter of 100µm (bilateral tolerance of 10µm), texture depth of 20µm (bilateral tolerance of 3µm) and texture surface roughness of 3µm (bilateral tolerance of 0.5µm) respectively. A confocal microscope with three dimensional surface profiler was used to measure the surface topography of the textured surfaces. It has been observed that with increase in laser power initially texture diameter has been reduced but found to be increased for the maximum power condition, while dimple depth and surface roughness of the textures found to be increased gradually. Also with increase in frequency has not a significant effect on the texture diameter but the texture depth and surface roughness has been enhanced drastically. In the similar way with increase in the laser speed and number of loops, initially there was decrease in the texture dimensions but as the speed and number of loops increased the texture dimensions also has a slight enhancement on it. It may be concluded that laser power and laser frequency has a significant impact on the texture dimensions as compared to laser speed and number of loops. Also it can be summarized that for achieving the targeted values of the texture dimensions like texture diameter, texture depth and texture surface roughness on the piston ring surface the laser power of 12W, 8W and 8W, laser frequency of 25 KHz, 25 KHz and 20 KHz, laser scan speed of 170 mm/sec, 140 mm/sec and 110 mm/sec and number of laser loops of 5, 4 and 2 may be used respectively.

KEYWORDS:

Confocal Microscope; Fiber Laser; Laser Power; Laser Texturing; Texture Dimensions

Copy the following to cite this article:

Patil A. S, Wakchaure V. D, Shirsat U. M. Effect of fiber Laser Process Parameters on Texture Dimensions Fabricated on Cast Iron Piston Ring Segments. Mat. Sci. Res. India;19(2).

|

Copy the following to cite this URL:

Patil A. S, Wakchaure V. D, Shirsat U. M. Effect of fiber Laser Process Parameters on Texture Dimensions Fabricated on Cast Iron Piston Ring Segments. Mat. Sci. Res. India;19(2). Available from: https://bit.ly/3dE1Aae

|

Introduction

The tribological properties of the interacting surfaces may be enhanced by the surface texturing of any one or both the surfaces in contact. The surface texturing methods like burnishing, vibro rolling, embossing, chemical etching, laser surface texturing etc. are generally used for the fabrication of textures on the interacting surfaces. Amongst all these laser surface texturing method is mostly used to fabricate the micro textures. This fabrication of micro-textures with an accurate dimensions is a big challenge in front of the researchers. Surface texturing is a popular approach to boost the performance of sliding mechanical parts in terms of coefficient of friction, wear and load carrying capacity. Attempts have been made by many of the researchers to evaluate the effect of laser process parameters on the texture dimensions. Among all techniques stated above the laser surface texturing is the most promising technique used to create an accurate and precise textures. If the requirement of the texture is very small to be used in applications like piston ring cylinder liner interface to fabricate the textures on outer surface of the piston ring. However the dimensions of the fabricated textures are significantly affected by input laser parameters such as laser power, laser scanning speed, laser frequency and laser loops. To get a desired surface texture dimension is a cumbersome procedure and therefore there is an essential requirement of evaluating the effect of laser parameters on the fabricated texture dimensions. Typically short laser loops of nanosecond (ns) and femtosecond (fs) are generally used for fabricating textures on metal surfaces. However such types of laser machines are too much expensive as compared to fiber laser machines with pulse duration in millisecond (ms) range. Many of the times the higher manufacturing cost is not acceptable which may be caused because of very costlier laser processing technology for surface texturing of metal components.

A wide use of lasers has been found to treat the surfaces of various materials due to its high precision, fast processing, low cost and local treatment 1-3. Various metals, semiconductors and polymers surface properties can be tailored with nanosecond pulsed lasers 4. The high pulse intensities due to non-linear laser pulses on the target material leads to the fabrication of accurate and precise textures 5. The wear and friction of metals and non-metals can be reduced with an effective tool like laser surface texturing. In the recent past period, large number of techniques were used by the researchers like embossing, etching, abrasive jet machining and micro casting 6-9 to modify the surface patterns. However, these techniques are costlier and forces some design constraints for the surface modification patterns. Therefore an alternate promising technique like laser surface texturing is used to get rid of the earlier techniques drawbacks for the fabrication of micro textures 10-15. The effect of various laser process parameters and its optimization was investigated by the various researchers for the materials like Nickel-aluminum bronze, stainless steel (SS316L, Ck45 steel, TiGr-2, Ti6Al4V, Inconel 625 etc. and found that grooves and dimples with least deterioration were obtained at higher laser power ranging of 12W to 18W, moderate scanning speed of 500 mm/s, moderate frequency 15 KHz to 50 kHz and pulse duration of 1500 ns 16-19.

Ytterbium fiber laser can be used for generation of micro textures of different geometries on hardened steel. It was concluded that laser power is directly proportional to the texture diameter as well as texture depth while laser frequency and laser scan speed provides inverse proportion with the dimple dimensions. The laser pulse length has not a significant effect on the texture dimensions. The laser treatment of Al 6082-T6 material was also carried out and researchers found that the effective laser process parameter for crack length were gas type with 57.54%, gas type with 76.20% for porosity the, gas type with 75.92% for roughness the 20-21. The nanosecond laser texturing on Ti6Al4V alloy sample shown that as laser power increases the depth of texture initially increases while it decreases with increase in power from 11W to 20.9W. Also texture depth decreases with increase in laser scanning speed from 10mm/s to 40mm/s reasonably. The depth of texture was not very much affected by the variation of laser frequency from 30 KHz to 60 KHz 22.

Some of the authors analyzed the different quality characteristics of surface patterns fabricated by various types of lasers. Morales et al.23 concluded that the pulse to pulse overlap and hatch distance has a significant effect on structure depth and large periodic modulation. Sugar et al.24 optimized the laser power, repetition rate and scanning speed which leads to excellent reduction of heat affected zone and re-cast layers which were formed around base metal tool steel. Xi et al.25 investigated that for a Ti6Al4V alloy as scanning speed varied from 10 mm/s to 40 mm/s there is decrease in texture depth while repetition rate had not a significant effect on its surface texture. Jiang et al.26 observed that 450 mm pitch of texture and 1.5 mm/s laser scanning speed has given a 0.1014 micro-texture depth ratio and the12.44% rate of area occupancy. Zhan et al.27 concluded that melt bulges, recast debris formation appears in grooves with nanosecond pulses as well as the reduction in thermal damage and heat affected zone was observed with decrease in the pulse duration for stainless steel surfaces.

Brizmer et al.28 shown that partial laser surface texturing revealed a good load-carrying capacity while evaluating a of thrust bearing. Furlan et al.29 fabricated periodic surface patterns with a spacing of 580 nm ± 20 nm on AZ31 Mg. Sampedro et al.30 concluded that there is a laser surface texturing has shown enhancement in wear resistance of AISI 316. Teixidor et al. 31 optimized surface roughness and channel width of a texture with a larger scanning speed of 400 mm/s and smaller pulse frequency of 35 kHz. Kong et al.32 demonstrated that enhanced laser energy is responsible for generating wider tracks as well as leads to increase in the material removal rate along with the deterioration of surface finish.

In the current study, the investigation of effect of fiber laser process parameters on the circular texture dimensions fabricated on the piston ring surface is carried out by varying the laser power, laser speed, laser frequency and number of loops over a wide range of values. This study has been carried out to understand the relation between various laser parameters and texture dimensions created on the piston ring surface.

Materials and Methods

The target material for fabricating the laser textures considered was an outer surface of a commercial piston ring segment. These piston ring segments were cut from the whole available commercial piston ring with the help of Electric Discharge Machining (EDM) as per the specimen requirement. The piston ring material specimen property details under experimentation are shown in Table 1. These cast iron piston ring specimens with Young’s Modulus of 250 Gpa, hardness of 410 HV and surface roughness of 0.482 µm were used for the fabrication of textures.

Table 1: Commercial piston ring details

|

Specimen

|

Chemical Content (%)

|

Surface Roughness-Ra (µm)

|

Hardness (HV),

|

|

Piston ring

|

Fe-92.662, C-3.61, Mn-0.80, Si-2.80, P-0.085, S-0.043

|

0.482

|

410

|

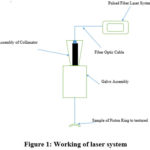

The fiber laser system with the specifications like maximum frequency of 500 KHz, maximum laser power of 20W and wavelength of 1064nm was used to fabricate textures on the outer surface of cast iron piston ring surface specimens. The working process of the fiber laser system is as shown in Figure 1. Also Figure 2 shows the actual image of the fiber laser machine.

The distance between the bottom of galvo and the specimen to be textured is kept equal to focal length of lens available in Galvo assembly. The varied laser input parameters were controlled through a serial port interconnected to a computer system are shown in Table 2. These varying input laser parameters like laser power, laser speed, laser frequency and number of loops were varied over a wide range of values to evaluate its effect on texture dimensions as discussed above.

Table 2: Input laser process parameters

| |

Input Laser Parameters

|

|

Sr. No.

|

Power (Watts)

|

Frequency (KHz)

|

Speed (mm/s)

|

Number of loops

|

|

1

|

4 to 20

|

25

|

180

|

1

|

|

2

|

10

|

5 to 25

|

180

|

1

|

|

3

|

10

|

25

|

50 to 170

|

1

|

|

4

|

10

|

25

|

180

|

1 to 5

|

The laser input parameters considered above are selected in a way to design the experiment so that one parameter was varied at a time by fixing all other 3 parameters fixed that is the use of “one at a time parameter approach” was done. The shape of targeted texture needs to be fabricated on the outer surface of the piston ring segment was of circular type for which approximate texture diameter, texture depth and texture surface roughness needs to be obtained were 100µm (bilateral tolerance of 10µm), 20µm (bilateral tolerance of 3µm) and 3µm (bilateral tolerance of 0.5µm) respectively. The experimental plan details are as shown in Table 3 along with the obtained results for the texture diameter, texture depth and texture surface roughness which were the averaged values of the texture diameter, depth and surface roughness considered for the textures fabricated on the ring surface. Laser power was varied from 4 watts to 20 watts keeping all other laser parameters constant. Similarly the laser frequency was varied from 5 KHz to 25 KHz, laser speed was varied from 50 mm/s to 170mm/s and number of loops were varied from 1 to 5. A Confocal microscope was used to measure the surface topography of the laser textured specimens. The average diameter and depth of the textured specimens is evaluated by averaging the texture dimensions considered at three different locations.

Table 3: Experimental input and output parameters.

|

|

Input Laser Parameters

|

Output texture parameters

|

|

Expt. No.

|

Power (Watt)

|

Frequency (KHz)

|

Speed (mm/s)

|

No. of loops

|

Texture Diameter (µm)

|

Texture Depth (µm)

|

Texture Surface roughness (µm)

|

|

1

|

4

|

25

|

180

|

1

|

123.51

|

4.44

|

0.657

|

|

2

|

8

|

25

|

180

|

1

|

116.411

|

21.76

|

2.765

|

|

3

|

12

|

25

|

180

|

1

|

107.507

|

26.261

|

4.23

|

|

4

|

16

|

25

|

180

|

1

|

108.541

|

23.144

|

5.166

|

|

5

|

20

|

25

|

180

|

1

|

116.525

|

31.745

|

3.153

|

|

6

|

10

|

5

|

180

|

1

|

125.5

|

2.374

|

0.815

|

|

7

|

10

|

10

|

180

|

1

|

129.359

|

8.744

|

4.473

|

|

8

|

10

|

15

|

180

|

1

|

126.58

|

14.448

|

2.525

|

|

9

|

10

|

20

|

180

|

1

|

125.5

|

15.686

|

3.434

|

|

10

|

10

|

25

|

180

|

1

|

104.03

|

16.555

|

3.385

|

|

11

|

10

|

25

|

50

|

1

|

102.901

|

30.54

|

4.3

|

|

12

|

10

|

25

|

80

|

1

|

98.084

|

15.895

|

2.451

|

|

13

|

10

|

25

|

110

|

1

|

107.13

|

23.069

|

2.702

|

|

14

|

10

|

25

|

140

|

1

|

111.841

|

22.962

|

6.591

|

|

15

|

10

|

25

|

170

|

1

|

102.993

|

14.768

|

3.545

|

|

16

|

10

|

25

|

180

|

1

|

118.09

|

17.344

|

3.043

|

|

17

|

10

|

25

|

180

|

2

|

89.242

|

31.838

|

2.127

|

|

18

|

10

|

25

|

180

|

3

|

118.222

|

25.429

|

4.442

|

|

19

|

10

|

25

|

180

|

4

|

116.782

|

21.901

|

2.864

|

|

20

|

10

|

25

|

180

|

5

|

108.251

|

34.499

|

2.779

|

Characterization of the textured piston ring specimen

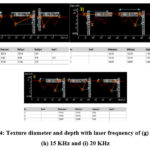

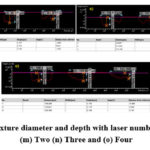

The fabricated textured cast iron piston ring specimens were characterized for the dimple/texture diameter, dimple/texture depth and dimple/texture surface roughness with the help of confocal microscope and three dimensional surface profiler. The two dimensional images obtained for the dimple diameter and dimple depth as shown in Figure 3 to 6, as well as the dimple surface values were noted from the interface of the confocal microscope. From Figures 3 to 6 it has been observed that average three number of dimples data for dimple diameter, dimple depth and dimple surface roughness were considered for evaluating output parameters. Following figures shows the data for some of the fixed and varied parameters as per the experimentation conducted during the project work. Figure 3a to 3f shows the dimple dimension data images for varying laser power of 12W, 16W and 20W. Also Figure 4g to 4i shows the dimple dimension data images for varying laser frequency of 10 KHz, 15 KHz and 20 KHz. In the similar manner Figure 5j to 5l shows the dimple dimension data images for varying laser scan speed of 80 mm/sec, 110 mm/sec and 140 mm/sec. As well as Figure 6m to 6o shows the dimple dimension data images for varying number of loops of 2, 3 and 4.

|

Figure 3: Texture diameter and depth with laser power of (a) and (b) 12 W, (c) and (d) 16W and (e) and (f) 20W.

Click here to View figure

|

|

Figure 5: Texture diameter and depth with laser scan speed of (j) 80 mm/sec (k) 110 mm/sec and (l) 140 mm/sec.

Click here to View figure

|

The measurement of all the texture/dimple dimensions were carried out with the help of confocal microscope and taking the average of the texture dimensions like diameter, depth and roughness.

Result and Discussions

The effect of various input laser parameters like laser power, laser frequency, laser scan speed and number of laser loops on the texture dimensions like texture diameter, texture depth and texture surface roughness were evaluated. During the tests only one parameter is varied from the set of input parameters by keeping all other input parameters fixed.

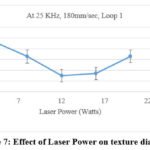

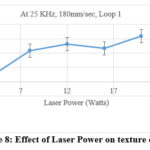

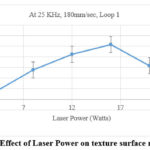

Effect of laser power

The effect of varying laser power on texture diameter, texture depth and texture surface roughness by keeping laser frequency, laser scan speed and number of loops constant is shown in Figure 7 to Figure 9. It can be seen from Figure 9 as the laser power increases from 4W to 12W at a constant laser frequency of 25 KHz, laser scan speed of 180 mm/s and a single laser loop the texture diameter decreases from 123.51µm to 107.507µm. But increase in more laser power from 12W to 20W resulted into increase in the texture diameter from 108.54µm to 116.525µm. Figure 8 shows that as the laser power increases at the same constant operating laser parameters there is gradual increase in the texture depth observed from 4.44µm to 31.745µm. In the similar manner Figure 9 shows that as laser power increases at the same constant operating laser parameters there is gradual increase in texture surface roughness which varies from 4.44µm to 31.745µm. Though initially as laser power increases there is decrease in texture diameter but overall it has been observed that the texture diameter, texture depth and texture surface roughness has been increased because of enhanced ablation rate due to increased laser power. The cast iron piston ring surface has been exposed to a laser beam such that material removal take place because of the laser energy supplied by the laser beam which is greater than the binding energy of the atoms present in the lattice of the ring material 20. Therefore in general as laser power increases the texture dimensions found to be increased but the texture surface roughness at higher power may be reduced as seen in Figure 9.

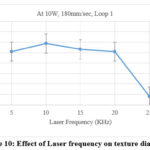

Effect of laser frequency

The effect of laser frequency on texture diameter, texture depth and texture surface roughness by keeping laser power, laser scan speed and number of loops constant can be analyzed from Figure 10 to Figure 12. It can be seen from Figure 10 that when the laser frequency varied from 5 KHz to 25 KHz by keeping all other parameters constant like laser power of 10W, laser scan speed of 180 mm/s and one number of laser loop, as laser frequency increases the texture diameter remains approximately constant from 125.500µm to 126.580µm but after 20Khz it reduces to 105.500µm. Figure 11 shows that as laser frequency increases the texture depth gradually increases from 2.374µm to 16.555µm. Also Figure 12 shows that as laser frequency increases the texture surface roughness initially increases from 0.815µm to 4.473µm then reduces to 2.525µm and approximately remains constant.

In general as the laser frequency increases there is reduction in the texture dimensions, in this case texture diameter and texture surface roughness has been reduced with increase in laser frequency but texture depth has been found to be increased. The texture diameter and texture surface roughness has been reduced here because the energy availability of the laser beam at lower frequency is at higher side as compared to the energy availability in laser beam at higher frequency. This leads to the high ablation rate at lower frequency of the laser beam 20. But the texture depth found to be slightly increased or approximately remains constant after 15 KHz this is because of the very small adjustable interval of laser frequency considered for the experimentation 22.

Effect of laser scan speed

The effect of laser scan speed on texture diameter, texture depth and texture surface roughness by keeping laser power, laser frequency and number of loops constant is shown in Figure 13 to Figure 15. It can be seen from Figure 13 that when the laser scan speed is varying from 50 mm/sec to 170 mm/sec by keeping other parameters constant initially the texture diameter decreases from 102.901µm to 98.084µm and again with increase in laser scan speed it increases up to 111.841µm. Figure 14 shows that as laser scan speed increases on an average there is a gradual decrease in the texture depth from 30.54µm to 14.708µm. Also Figure 15 shows that as laser scan speed increases the texture surface roughness decreases from 4.3µm to 3.5µm but showing slight fluctuations in the roughness values.

It has been revealed from the literature survey that texture dimensions reduces as laser scan speed increases. This is due to the fact that as speed of laser beam increases it does not get sufficient time for the removal of the material from the targeted metal surface and therefore ablation rate decreases which leads to reduction in the texture dimensions 20,22.

Effect of number of loops

The effect of number of laser loops on texture diameter, texture depth and texture surface roughness by keeping laser power, laser frequency and number of laser loops constant from Figure 16 to Figure 17. It can be seen from Figure 16 that by varying the number of loops from 1 to 5 while keeping all other laser parameters constant, initially the texture diameter almost remains constant ranging from 118.090µm to 108.251µm. It indicates that there is no significant effect of number of loops on the texture diameter. From Figure 17 and 18 it has been observed that as the number of loops goes on increasing there is fluctuation in texture depth as well as texture surface roughness as number of loops increases.

Conclusion

The laser texturing of cast iron piston ring segments was carried out by varying the various laser parameters and the following conclusions can be drawn from it,

Laser power has a positive effect on the texture depth and texture surface roughness which gradually increases with increase in laser power while texture diameter decreases initially but after certain increase in laser power texture diameter also found to be increased.

Laser frequency has a significant effect on texture depth and texture surface roughness which leads to gradual increase of it with increase in laser frequency but it has been found that laser frequency has not a significant effect on texture diameter.

Laser scan speed has not a significant effect on texture diameter as well as texture depth and texture surface roughness. All are found to be gradually decreasing with increase in laser scan speed.

Laser number of loops found to be less significant as the texture diameter almost remains constant towards the targeted value with increase in number of loops. While texture depth and texture surface roughness gradually fluctuates from lower to higher values as per increase in number of loops.

To get an approximate targeted value of texture diameter of 100 µm (bilateral tolerance of 10µm), texture depth of 20µm (bilateral tolerance of 3µm) and texture surface roughness (bilateral tolerance of 0.5µm) the laser power of 12W, 8W and 8W may be used respectively by keeping all other parameters constant as specified.

To get an approximate targeted value of texture diameter of 100 µm (bilateral tolerance of 10µm), texture depth of 20µm (bilateral tolerance of 3µm) and texture surface roughness (bilateral tolerance of 0.5µm) the laser frequency of 25 KHz, 25 KHz and 20 KHz may be used respectively by keeping all other parameters constant as specified.

To get an approximate targeted value of texture diameter of 100 µm (bilateral tolerance of 10µm), texture depth of 20µm (bilateral tolerance of 3µm) and texture surface roughness (bilateral tolerance of 0.5µm) the laser scan speed of 170 mm/sec, 140 mm/sec and 110 mm/sec respectively by keeping all other parameters constant as specified.

To get an approximate targeted value of texture diameter of 100 µm (bilateral tolerance of 10µm), texture depth of 20µm (bilateral tolerance of 3µm) and texture surface roughness (bilateral tolerance of 0.5µm) the number of laser loops of 5, 4 and 2 respectively may be used by keeping all other parameters constant as specified.

Acknowledgement

The Authors like to thank M/s. R. R. Engravers, Nashik and I. R. Technology Services Pvt. Ltd., Navi Mumbai for providing the laser surface texturing and characterization facility of samples.

Conflict of Interest

We declare that there are no conflict of interest regarding the research work carried out and the publication of this article.

Funding Sources

This research work is not sponsored or funded by any institute/organization.

References

- J.B. Bukola et.al, “Corrosion characteristics of as-cast aluminium bronze alloy in selected aggressive media”, J. Miner. Char. Eng., 1, 245-249, 2013

CrossRef - C.N. Nwambu et.al, “Modification of the structure and mechanical properties of aluminum bronze (Cu-10%Al) alloy with zirconium and titanium”, Int. J. Sci. Eng. Res., 8, 1, 2017

- Dipanjan Dey et.al, “Hardness and wear behaviour of multiple component coating on Ti-6Al-4V substrate by laser application”, Optik, 1, 163555, 2020

CrossRef - Yutong Wang et.al, “Nanosecond laser texturing with hexagonal honeycomb micro-structure on Titanium for improved wettability and optical properties”, Optik 192,162953, 2019

CrossRef - S. Nolte et.al, “Ablation of metals by ultra-short laser pulses”, J. Opt. Soc. Am. B., 14 , 2716-2722, 1997

CrossRef - B. Podgornik et.al, “Effectiveness and design of surface texturing for different lubrication regimes”, Meccanica 47, 1613-1622, 2012

CrossRef - S. Xu et.al, “Development of low-cost deformation based micro surface texturing system for friction reduction”, Int. J. Precis. Eng. Manuf., 17, 1059-1065, 2016

CrossRef - H. Costa et.al, “Some innovative surface texturing techniques for tribological Purposes”, Proc. Inst. Mech. Eng., Part J: J. Eng. Tribol, 229, 429-448, 2015

CrossRef - X. Su et.al, “A multi-phase micro-abrasive jet machining technique for the surface texturing of mechanical seals”, Int. J. Adv. Manuf. Technol. 86, 2047-2054, 2016

CrossRef - A.H. Cannon et.al, “Casting metal microstructures from a flexible and reusable mold”, J. Micromech. Microeng, 095016, 2009

CrossRef - A. Bharatish et.al, “Effect of scanning speed and tin content on the tribological behavior of femtosecond laser textured tin-bronze alloy”, Opt. Laser. Technol., 108, 17-25, 2018

CrossRef - A. Ghiotti et.al, “Tribological behavior of high thermal conductivity steels for hot stamping tools’”, Tribol. Int., 97, 412-422, 2016

CrossRef - I. Etsion, “State of the art in laser surface texturing”, Trans. ASME-F-J. Tribol. , 127, 248, 2015

CrossRef - D. He et.al, “Improving tribological properties of titanium alloys by combining laser surface texturing and diamond-like carbon film”, Tribol. Int., 82, 20-27, 2015

CrossRef - L. Romoli et.al, “Experimental characterization of the inner surface in micro-drilling of spray holes: a comparison between ultra-short pulsed laser and EDM”, Opt Laser. Technol. , 56 , 35-42, 2014

CrossRef - A. Bharatish et.al, “Optimization of laser texture geometry and resulting functionality of nickel aluminum bronze for landing gear applications”, International Journal of Lightweight Materials and Manufacture, 4, 346-357, 2021

CrossRef - Saravanan Kandaswamy Ganeshan et.al, “Optimization of Laser Parameters and Dimple Geometry Using PCA-Coupled GRG”, Journal of Mechanical Engineering, 67, 10, 525-533, 2021

CrossRef - T. D. Dikova et.al, “Technological parameters optimization in picosecond laser texturing of titanium surfaces”, Journal of Physics: Conference Series, 1859, 012037, 2021

CrossRef - S. Fidan et.al, “Laser parameter optimization for surface texturing of Inconel 625”, Materialwiss Werkstofftech, 52, 289–307, 2021

CrossRef - Parul Mishra et.al, “Optimization of Ytterbium laser parameters for texturing of steel surfaces”, An International Conference on Tribology, TRIBOINDIA 2018

CrossRef - Timur Canel et.al, “Laser parameters optimization of surface treating of Al 6082-T6 with Taguchi method”, Optics and Laser Technology, 120, 105714, 2019

CrossRef - Xiaoying Xi et.al, “Effect of Laser Processing Parameters on Surface Texture of Ti6Al4V Alloy”, IOP Conf. Series: Materials Science and Engineering, 563, 022052, 2019

CrossRef - Alfredo I. et.al, “Influence of processing parameters on surface texture homogeneity using direct laser interference patterning”, Opt Laser. Technol., 107, 216-227, 2018

CrossRef - Peter Sugar et.al, “Laser surface texturing of tool steel: textured surfaces quality evaluation”, Open Eng., 6, 1, 2016

CrossRef - Xiaoying Xi et.al, “Effect of laser processing parameters on surface texture of Ti6Al4V alloy”, IOP Conf. Ser. Mater. Sci. Eng., 563, 2205, 2019

CrossRef - Suqin Jiang et.al, “Study on surface micro-texture of characterization and laser processing on 45 steel,” IOP Conf. Ser. Mater. Sci. Eng., 490, 052035, 2019

CrossRef - Junjie Zhang et.al, “Laser surface texturing of stainless steel and effect of pulse duration on texture’s morphology and frictional response”, Adv. Eng. Mater., 21 (3), 1801016, 2018

CrossRef - V. Brizmer et.al, “A laser surface textured parallel thrust bearing”, Tribol. Trans., 46 (3) 397-403, 2003

CrossRef - Valentina Furlan et.al, “Sub-micrometric surface texturing of AZ31 Mg-alloy through two-beam direct laser interference patterning with a Ns pulsed green fiber laser”, Appl. Surf. Sci., 423, 619-629, 2017

CrossRef - J. Sampedro et.al, “Surface functionalization of AISI 316 steel by laser texturing of shaped micro cavities with picosecond pulses”, Physics Procedia, 39, 636-641,2012

CrossRef - D. Teixidor et.al, “An Experimental Analysis of Process Parameters to Manufacture Micro-channels in AISI H13 Tempered Steel by Laser Micro-milling”, AIP Conference Proceedings 1431, 543, 2012

CrossRef - Ming Chu Kong et.al, “Surface quality analysis of titanium and Nickel-based alloys using picosecond laser”, Procedia CIRP, 13, 417-422, 2014

CrossRef

Views: 341

This work is licensed under a Creative Commons Attribution 4.0 International License.

, Vishnu D. Wakchaure2

, Vishnu D. Wakchaure2 and Uddhav M. Shirsat3

and Uddhav M. Shirsat3

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal