Abhishek S. Suvarna1, Akash Katagi1, Jackson Pasanna1, Sunil Kumar1, Pramod V. Badyankal1, Suresh K. Vasudeva2 and Basavaraju Bennehalli*2

1Department of Mechanical Engineering, Alva’s Institute of Engineering and Technology, Mijar-574225, Visvesvaraya Technological University, Karnataka, India.

2Department of Chemistry, Alva’s Institute of Engineering and Technology, Mijar-574225, Visvesvaraya Technological University, Karnataka, India.

DOI : http://dx.doi.org/10.13005/msri/120110

Article Publishing History

Article Received on : 13 Mar 2015

Article Accepted on : 10 Apr 2015

Article Published : 11 Apr 2015

Plagiarism Check: Yes

Article Metrics

ABSTRACT:

The present investigation focuses on the fabrication and mechanical characterization of alkali treated natural abaca fiber reinforced urea formaldehyde composites. The composites were prepared by means of compression moulding, and then the effects of fiber loading on mechanical properties such as tensile strength, flexural strength and impact strength were investigated. The composite with 40 wt% abaca fibers gave excellent tensile strength and flexural strength showing that it has the most superior bonding and adhesion of all the composites. In particular, the highest value, 10.02 kJ/m2 of charpy impact strength is observed in the composite with 50 wt% abaca fiber. This work revealed the potential of using abaca fibers in fiberboard.

KEYWORDS:

Polymer composites; Mechanical properties; Abaca fibers; Urea-Formaldehyde resin; Alkali treatment

Copy the following to cite this article:

Suvarna A. S, Katagi A, Pasanna J, Kumar S, Badyankal P. V, Vasudeva S. K, Bennehalli B. Mechanical Properties of Abaca Fiber Reinforced Urea Formaldehyde Composites. Mat.Sci.Res.India;12(1)

|

Copy the following to cite this URL:

Suvarna A. S, Katagi A, Pasanna J, Kumar S, Badyankal P. V, Vasudeva S. K, Bennehalli B. Mechanical Properties of Abaca Fiber Reinforced Urea Formaldehyde Composites. Mat.Sci.Res.India;12(1). Available from: http://www.materialsciencejournal.org/?p=1678

|

Introduction

Conventionally, in aerospace, automotive and packaging industries, synthetic fiber reinforced composites are widely used because of their greater strength and stiffness. But synthetic fibers are expensive and not ecofriendly. So, of late biofibers are replacing synthetic fibers which are extensively used as reinforcements in composites and these materials are gaining popularity as potential structural materials because they are abundantly available, renewable, sustainable, light weight, non abrasive, biodegradable, economical and ecofriendly. In spite of these positive points, natural fibers as reinforcements suffer certain drawbacks. Natural fibers are hydrophilic in nature due to the presence of hydroxyl groups which increases moisture sensitivity, where as matrix material is hydrophobic in nature. This leads to poor interfacial adhesion between fiber and matrix. The main role of matrix is to transfer the load on to the fibers at the interface. Efficient load transfer is possible if there is proper bonding between fiber and matrix. Poor adhesion does not give optimum properties for the composites. Compatibility between fiber and matrix can be improved by suitable chemical treatments. Moisture absorption in a composite is influenced by volume fraction of fiber, voids, viscosity of the matrix, humidity and temperature. Moreover the properties of natural fibers depends on the climate, location and weather from which they are grown and also depends on fiber length, age and fiber extraction method and hence very difficult to predict the composite properties [1-7].

The use of synthetic fibers as reinforcements like glass , kevlar, carbon fibers are very expensive and natural fibers like abaca, areca, jute, cotton, sisal, coir etc. are used as reinforcements in polymer composites because of innumerable advantages like flexibility during processing, available in abundance, light in weight, cheaper, high strength to weight ratio, renewable recyclable and biodegradable [8,9]. But the disadvantages associated with the use of these fibers as reinforcements are: Fibers are hydrophilic and matrix is hydrophobic which results in non uniform dispersion of fibers in the matrix leading to difficulties in fabrication of composites.

The botanical name of abaca is Musa Textilis which is a species of banana grown extensively in Philippines. It is also called Manila hemp. Abaca plant belongs to the banana family Musaceae, Genus Musa and species Musa Textilis. The Republic of the Philippines is the largest producer producing around 50,000 tonnes per annum and according to Indian survey the production of abaca fiber is 24,875 tonnes per annum. The abaca fibers are used in the production of handicraft products such as fashion accessories, decorative accessories, furniture, garments, textile, packaging materials, and table-top accessories. Abaca fibers are also used in sinamay weaving [10,11].

Abaca plants are grown extensively and the fibers are actually the waste product of abaca cultivation and without any additional expenses they can be used for industrial purposes [12]. This study mainly focuses on the fabrication of alkali treated abaca fiber reinforced urea-formaldehyde composites and to study the effect of fiber loading on the tensile, flexural and impact strength of the composites.

Materials and Methods

Materials

Abaca fibers were collected from the Maruthi Peach Finishing Company, Tirupur, Chennai, India and Analytical grade reagents were purchased from Qualigens Company and used as received. The urea formaldehyde resin and corresponding hardener were procured from Akolite Synthetic Resins, Mangalore.

Alkali Treatment of Abaca Fiber

The fibers are first dewaxed by soaking in 1:2 mixtures of ethanol and benzene for 72 h, followed by washing with deionised water and then air dried. The dewaxed fibers were immersed in 6% NaOH solution at room temperature (30-32 oC) for 1h, where the total volume of the solution was 15 times the weight of the fibers. The fibers were kept in alkaline solution for 36 h at a temperature of 30 oC; they were thoroughly washed in running water and then neutralized with 2% acetic acid solution. Lastly, the fibers were washed again in running water to remove the last traces of acid sticking to it, so that the pH of the fibers was approximately 7. Then, they were dried at room temperature for 48 h to obtain alkali-treated fibers [12,13].

Composite Fabrication

Abaca fibers were air dried for 24 h at laboratory temperature and then dried in oven for 24 h at 105 °C to remove free water present in the fiber. The dried fibers were subsequently cut into 10 mm; they were mixed with urea-formaldehyde resin. The composite preparation process was performed in the following order by using random mixing technique. First, the heat press was pre-heated to 60 oC. Then the pressure was set as 0 MPa and the temperature raised to 100 oC. After that the pressure was raised to 5 MPa and temperature was raised to 140 oC. Further, raised the pressure to 8 MPa, maintained the pressure and temperature for 30 min. Finally, lowered the pressure to 0 MPa, lowered the temperature to 30 oC and composite plate was removed from the heat press. The specimens were post cured for 15 days before the test. The moulds have been prepared with dimensions of 255 mm × 255 mm × 4 mm.

Composite Characterisation

The prepared composite slabs were cut into required dimensions with the help of zig saw for tests. The appropriate ASTM methods were followed while preparing the specimens for test. At least eight replicate specimens were tested and the results were presented as an average of tested specimens. The tests were conducted at a standard laboratory atmosphere, 30±2 oC and 65% relative humidity. The tensile strength measurement was carried out according to ASTM D638 [Type III] standards, the 3-point bending test method according ASTM D 790 with the loading speed of 2 mm/min and Charpy impact strengths of the specimens were determined with an impact tester with a striking velocity of 2.9 m/s.

Results and Discussion

Tensile Strength

The properties of bio composites are not only determined by the components constituting it, but also affected by many other factors. However, fiber geometry, fiber orientation, fiber length and fiber loading plays key role in determining the properties. When load is applied on to the matrix, stress transfer takes place at the interface along the fiber length and at the ends of the fiber and hence the extent of load transfer becomes the function of fiber length.

Tensile strength is the ability of a material to withstand a pulling force. It is measured as force per cross-sectional area. A composite’s tensile strength is tested using a moulded dumbbell. The dumbbell is placed in the grips of a tensile tester. When the tester is activated, the dumbbell is pulled steadily until it breaks. The force being exerted on the sample at the time of rupture is said to be the samples tensile strength. Tensile strength is an intensive property and hence its value does not depend on the size of the test specimen but depends on the methods of preparation of the specimen, the presence of surface defects and the temperature of the test environment and material.

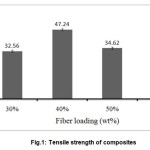

In this work, abaca fiber reinforced urea-formaldehyde resin composites were fabricated with different fiber loadings of 30%, 40%, 50% and 60% and were evaluated for tensile properties. It is a must to know optimum fiber loading to get good tensile properties. So, the variations of tensile strength with different fiber loadings were studied and results are presented in Figure 1.

From Figure 1 it is clear that, tensile strength of composites increased with increase in fiber loading up to 40% and then decreased with increase in fiber loading. Amongst all the composites prepared, composite with 40% fiber loading showed maximum tensile strength of 47.24 MPa. It has been reported that the tensile strength of abaca fiber reinforced polypropylene composites showed increasing tendency up to 40% fiber loading and then decreased with increase in fiber loading. This can be attributed to better fiber distribution in matrix, good fiber matrix and less fiber fractures at 40% fiber loading [14,15]. The observed tensile strength values of composites can also be explained based on the fact that the alkali treatment of fiber removes lignin and hemicelluloses and exposes more hydroxyl groups on the fiber surface making them available for bonding with matrix and improving the adhesion between the fiber and matrix. Not only that, it also cleans the surface, reduces fiber diameter and increases the aspect ratio, increases stress transfer capacity thereby increasing the tensile strength.

Flexural Strength

Flexural strength, a mechanical parameter is the materials ability to resist deformation under load. It is the maximum stress experienced by the material at the point of rupture. It is measured using a three point flexural test or bending test. It is an important calculation for many builders and designers in engineering and architectural fields to know the weight bearing capacity of many materials. Based on these calculations, it is possible to choose appropriate materials for buildings, industrial machinery, cars, basic consumer appliances etc. It plays a significant role in civil, mechanical, aerospace engineering and design.

Many researchers revealed that increase in fiber loading as well as chemical treatment of the natural fibers increased the mechanical properties of the composites like tensile and flexural properties [14,15]. Flexural strength of bamboo/epoxy composites increased with increase in fiber volume up to 30% and then decreased. This decrease is due to poor interfacial bonding resulting in spaces between fiber and matrix generating a weak structure. Chemical treatments increased the flexural strength due to removal of outer fiber surface, increase in cellulose content and interfacial adhesion [16].

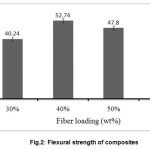

Flexural properties showed similar trends as that of the tensile strength. The effect of fiber loading on the flexural strength of abaca/urea-formaldehyde composites is depicted in Figure 2.

It is clear that flexural strength is greatly influenced by fiber contents. The flexural strength of composites increased up to 40% fibers loading and then decreased with the increase in fiber loading. This is because at 40% fiber loading, there is better fiber distribution in matrix, less fiber fractures and effective transfer of load from matrix to fibers. As fiber loading increased beyond 40%, flexural strength decreased due to the poor interfacial adhesion and inefficient stress transfer from matrix to fibers [15]. The flexural strengths of 30%, 40%, 50% and 60% fiber loadings are 40.24, 52.74, 47.80 and 34.02 MPa respectively. For 40% fiber loading flexural strength increased by 31% compared to 30% fiber loading and for 50% fiber loading it decreased by 9.36% compared to 40% fiber loading. These results clearly indicated that the alkali treatment of fiber provided better interlocking at the interface by making the surface rough and thereby improving fiber matrix adhesion.

Impact Strength

Impact strength is the capability of the material to withstand a suddenly applied load and is expressed in terms of energy (Joules). Charpy impact test determines the amount of energy absorbed by a material during fracture and it is a measure of materials toughness. Materials toughness is its ability to absorb energy during plastic deformation. It acts as a tool to study brittle-ductile transition. Brittle materials have low toughness and they can bear a small amount of plastic deformation. On impact, the energy of the pendulum is transferred to the test specimen and a part of the energy is consumed during fracture of the specimen. The total energy absorbed by the polymer composite is the sum of the energy consumed during plastic deformation and the energy needed for creating new surfaces. The impact properties of composite materials are directly related to its overall toughness. Composite fracture toughness is affected by interlaminar and interfacial strength parameters.

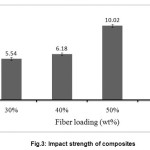

In this study, alkali treated abaca/urea-formaldehyde resin composites were fabricated with different fiber loadings of 30%, 40%, 50%, and 60% and impact energy absorbed for all composites are given in Figure 3.

The impact strength of composite with 30% fiber is 5.54 kJ/m2. With increase in fiber loading from 30 to 50%, the impact strength increases by 80.87%. With further increase in fiber loading from 50% to 60%, there is a significant decrease in impact strength. The impact strength of natural fiber reinforced polymer composites is influenced by many factors including fiber aspect ratio, fiber rigidity, matrix fracture, fiber-matrix debonding and fiber pull out. It has been reported that the Charpy impact strength decreases with enhanced fiber-matrix adhesion. For the composite with 30% fiber, the resin is adequate and excessive. Hence, the interfacial friction stress and chemical bond between matrix and fiber is generally superior when compared to other samples. This probably causes a drop in toughness and can explain why the impact strength is much lesser. Moreover, the greater strength of composite with 50% may be related with proper interfacial adhesion between the fiber and matrix; the fibers are of reasonable amounts and act as stress transferring medium. In addition, the interspaces and stress concentrations increases with the increased fiber loading. These fibers could have acted as crack instigation points during impact. Therefore, inferior impact strength is obtained in the composite containing 60% fiber [17].

Conclusions

In this paper, mechanical properties of abaca fiber reinforced urea-formaldehyde resin composites have been discussed. The composite with 50% abaca fiber has the optimal Charpy impact strength, 10.02 kJ/m2. Whereas the Tensile and flexural properties are proved to be excellent in the composite with 40% fiber loading under the present experimental conditions adopted. Hence, the applications of these composites in fiberboard can be extended.

Acknowledgements

The author, Basavaraju Bennehalli is thankful to the Vision Group on Science & Technology, Department of IT, BT and Science & Technology, Government of Karnataka for financial support in the form of sanctioning a Research Project to carry out the present investigation (grant number VGST/CISEE/2012-13/282 dated March 16, 2013).

References

- Libo Y., Chouw N. And Yuan X., J. Reinf. Plast. Compos., 31, 425 (2012).

CrossRef

- Rahaman R., Hasan M., Huque M. and Islam N., J. Reinf. Plast. Compos., 29, 445 (2011).

CrossRef

- Nam T.H., Ojihara S., Tung N.H. and Kobayashi S., Composites Part B, 42, 1648 (2011).

crossRef

- Thakur V.K. and Thakur M.K., Carbohydr. Polym., 109, 102 (2014).

CrossRef

- Dhakal H.N., Zhang Z.Y. and Richardson MO., Compos. Sci. Technol., 67, 1674 (2007).

CrossRef

- Onal L. and Karaduman Y., J. Comp. Mater., 43, 1751 (2009).

CrossRef

- Bachitar D., Sapuan S.M. and Hamdan M., International Journal of Automotive and Mechanical Engineering,1, 79 (2010).

CrossRef

- Bledzki A.K., Faruk O. and Mamun M.A., Polimery, 53, 120 (2008).

- Singha A.S. and Thakur, V.K., EJ Chem., 6, 34 (2009).

CrossRef

- Bledzki A.K. and Faruk O., eXPRESS Polymer Letters, 1, 755 (2007).

CrossRef

- Agung E.H., International journal of the Physical Sciences, 6, 2100 (2011).

- Ramadevi P., Dhanalakshmi S., Basavaraju B. and Srinivasa C.V., Chem. Sci. Trans., 2, 413 (2013).

CrossRef

- Ramadevi P., Dhanalakshmi S., Basavaraju B. and Srinivasa C.V., Bio Resources, 7, 3515 (2012).

- Pothan L.A. and Thomas S., Compos. Sci. Technol., 63, 283 (2003).

CrossRef

- Ratna Prasad A.V., Mohana Rao K. and Nagasrinivasulu G., Indian J. Fiber Text. Res., 34, 162 (2009).

- Srinivasa C.V., Basavaraju B., Mownesh G.K. and Raghu Patel GR., Bio Resources, 5, 1845 (2010).

- J. B. Zhong, J. Lv, C. Wei, express Polymer Letters, 1, 681 (2007).

CrossRef

Views: 4,843

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal