Introduction

General

Concrete is regarded as a maintenance-free, long-lasting material. “Cement, fine aggregate, coarse aggregate, and water” are the ingredients of concrete. The use of huge amounts of cement and fine aggregate is made possible by the crucial role that concrete plays roads, among other things. The energy crisis has made matters worse by driving up the price of producing Portland cement. Depending on the percentage which is already a very expensive material and accounts for a sizeable portion of the total building costs of any project. 1 This paper presents the result of utilization of waste from thermal power plants to improve some engineering properties of concrete. Coal bottom ash (CBA) and fly ash were utilized in partial replacement for fine aggregates and cement respectively in the range of 0, 5, 10, 15 & 20% (equal percentages). The results of compressive strength at 7, 28, 56 & 90 days curing are presented because of the pozzolanic reaction; other properties investigated include physical properties, fresh concrete properties and density. The results showed that for a grade 35 concrete with a combination of CBA and fly ash can produce 28 day strength above 30 MPa.

2,3 it was observed that the greatest increase in compressive, splitting tensile strength, and flexural strength compared to that of the conventional concrete was achieved by substituting 30% of the natural fine aggregates with industrial by-product aggregates. The inclusion of waste foundry sand and bottom ash as fine aggregate does not affect the strength properties negatively as the strength remains within limits except for 60% replacement. The morphology of the formations arising as a result of the hydration process was not observed to change in the concrete with varying percentages of waste foundry sand and bottom ash.4 The search for any such material, which can be used as an alternative or as a supplementary for cement should lead to global sust ainable development and lowest possible environmental impact. Concrete property can be maintained with advanced mineral admixtures such as blast furnace slag powder as partial replacement of cement 5 to 30%. Compressive strength of blast furnace slag concrete with different dosage of slag was studied as a partial replacement of cement. From the experimental investigations, it has been observed that, the optimum replacement of Ground Granulated Blast Furnace Slag Powder to cement without changing much the compressive strength is 15%.[5]. IS 383 (1970), ‘Specifications for coarse and fine aggregates from natural sources for concrete’ Second revision,Bureau of Indian Standards,New Delhi 5 IS: 456-2000, ‘Indian Standard Code for Practice for Plain and Reinforced Concrete’ Bureau of Indian Standards, New Delhi, India 6 IS: 516-1959, ‘Indian Standard Code for Practice: Methods of Test for Strength of Concrete’ Bureau of Indian Standards, New Delhi, India[6].IS: 10262-2009 ‘Recommended Guidelines for Concrete Mix Design’ Bureau of Indian Standards, New Delhi, India. 7. IS: 12269-1987 ‘Specifications for 53-Grade Portland Cement’ Bureau of Indian Standards, New Delhi, India.8 The study aims at evaluating the performance of concrete containing metakaolin and bottom ash replacing cement and fine aggregate on strength and workability properties of concrete. The results showed that the combination of metakaolin and bottom ash provides a positive effect on mechanical properties. The samples incorporating the concrete with 10% metakaolin and 45% bottom ash showed better strength than that of the normal concrete.9 The results of the physical and chemical properties of WBA were discussed. Different concrete mixes with constant water to cement ratio of 0.55 were prepared with WBA in different proportions as well as one control mixed proportion. The mechanical properties of special concrete with 30% WBA replacement by weight of natural sand is found to be an optimum usage in concrete in order to get a favourable strength and good strength development pattern over the increment ages.10 This study was to investigate the effect of use of coal bottom ash as partial replacement of fine aggregates in various percentages (0–30%), on concrete properties such as compressive strength, spiltting tensile strength test, flexural strength and modulus of elasticity and also the effect of microsilica in bottom ash concrete having maximum compressive strength. The test results of this research work indicates that at fixed water cement ratio, workability decreased with the use of coal bottom ash as a replacement of fine aggregate in concrete. Compressive strength of bottom ash concrete at the curing age of 28 days was increased compared to control concrete. Splitting tensile strength of concrete improved at percentages of replacement of bottom ash. The modulus of elasticity decreased with the use of coal bottom ash at all replacement levels.11 The research work carried out included an experimental investigation on strength properties of concrete made with 2.5% to 20% replacement of cement by quarry dust of less than 75 micron particle size. The tests were carried out to find the compressive strength, splitting tensile strength and flexural strength on specimens.Results showed that up to 7.5 % replacement of cement by quarry dust there was no reduction in compressive strength, splitting tensile strength and flexural strength.12 The results of the physical and chemical properties of WBA were discussed. Different concrete mixes with constant water to cement ratio of 0.55 were prepared with WBA in different proportions as well as one control mixed proportion. The mechanical properties of special concrete with 30% WBA replacement by weight of natural sand is found to be an optimum usage in concrete in order to get a favourable strength and good strength development pattern over the increment ages.13 M.S. Shetty, S.Chand (2010), ‘Concrete technology, theory, and practice’ Tata McGrah Hill Company Ltd., New Delhi 14 This study reviews the characteristics of Concrete incorporated with Bottom Ash as partial replacement for fine aggregates, with a main focus on the mechanical properties such as Compressive strength, splitting tensile strength, flexural strength etc. Ten different research papers are reviewed. The practical use of Bottom ash shows a great contribution to waste minimization as well as resources conservation.15 This study is focused on the use of coal bottom ash from Tefereyre (Niger) power plant coal-fuelled, as a fine aggregate in cementitious mortar. Various volume fractions of natural sand (0%, 10%, 20%, 30%, 40%, 50%, 75%, and 100%) were replaced by the same volume of fine aggregates of coal bottom ash. In order to determine the effect of coal bottom ash incorporation on the composites obtained, fresh and dry density water absorption, porosity, thermal conductivity, ultrasonic pulse velocity, gas permeability and microstructure analyses were investigated.

Ground Granulated Blast Furnace Slag (GGBS)

In the batching plant of the concrete producer, GGBS cement is combined with Portland cement, aggregates, and water to create concrete. The mix’s normal proportions of water, cementitious material, and aggregate stay the same. On a weight-for-weight basis, GGBS is used in place of Portland cement in construction projects. For GGBS, replacement ratios might in the limit from 30% to 85%. The majority of the period, 40 to 50%, is utilized. Concrete constructed with GGBS cement will cost around the same as concrete manufactured with regular Portland cement because it is somewhat less expensive than Portland cement.

One key benefit of GGBS is its positive impact on concrete durability. The inclusion of GGBS enhances the resistance of concrete to chemical attack and improves long-term performance in aggressive environments. Its pozzolanic and latent hydraulic properties contribute to the reduction of permeability, making concrete less susceptible to deterioration from harsh conditions.

GGBS is recognized for its ability to enhance workability and reduce heat of hydration in concrete mixes, making it particularly useful in large-scale construction projects.

Applications of GGBS

Because GGBS concrete is more durable, it may extend a building’s lifespan from fifty to one hundred years. As a result, it is increasingly being used in Europe, the US, and Asia.

GGBS cement causes concrete to set more slowly than regular Portland cement, but it also keeps its strength longer under manufacturing conditions. GGBS cement is made from “high-slag blast furnace cement (HSBFC) and Portland blast furnace cement (PBFC)”, both as the GGBS materials utilize as the percentage of 30 to 70%. Hydration heat is thus decreased. The application of GGBS in concrete technology continues to evolve, with ongoing research focusing on optimizing its use for diverse applications, including high-performance concrete, self-compacting concrete, and more environmentally friendly construction practices. Overall, GGBS stands as a versatile and eco-friendly material, playing a crucial role in enhancing the performance and sustainability of concrete structures.

Pond Ash

Pond ash, also known as ash pond residue, is a byproduct generated from the combustion of coal in thermal power plants. It is primarily composed of fine particles and ash that settle in ash ponds or lagoons adjacent to power plants. Pond ash is a valuable resource with potential applications in various industries, particularly in construction and infrastructure development.

When properly processed and utilized in concrete mixes, pond ash can contribute to improved workability, durability, and strength of the resulting structures. Its pozzolanic properties make it an effective partial replacement for cement, leading to reduced environmental impact and the efficient utilization of industrial waste.

Research and development in the field of materials engineering are continually exploring innovative ways to incorporate pond ash into construction materials, showcasing its potential to enhance sustainability in the construction industry. As industries strive for more eco-friendly practices, the utilization of pond ash stands out as a promising avenue for recycling and repurposing industrial byproducts.

One such material, pond ash, is a waste extrude from thermal power plants that can be intrude concrete as fine aggregate instead of natural sand. Researchers have a social obligation to support and contribute to the 3 Rs: reduce, reuse, and recycle, thereby supporting sustainable construction, by encouraging the use of such waste materials.

Benefits of Pond Ash

On four- or six-lane highways, a significant amount of pond ash—up to 55% replacement of cement—is utilized to create dry lean concrete.

Need for this research

In order to manufacture concrete, one of the essential ingredients is ordinary Portland cement (OPC). As a major contribution to the greenhouse effect and global warming, carbon dioxide (CO2) gas produced during the cement manufacturing process needs to be replaced totally or at least partially by another material. Additionally, natural sand that meets Indian Standards is getting harder to find and more expensive due to government regulations, illegal dredging carried out by the sand mafia, difficulty accessing the river basis through the rainy term, and failure to meet IS standards.

Literature review

General

Many Researchers have studied the properties of concrete with GGBS and Pond Ash. A few of literatures are presented in this chapter.

Er. Kimmi Garg et al (2016)

“Cement, fine aggregate, coarse aggregate, and water” are the ingredients of concrete. Concrete is used in enormous quantities because it is essential to the construction of infrastructure.

Concrete mixes including GGBS in place of some of the cement have demonstrated improved strength and durability. This is because GGBS contains reactive silica, which provides high compatibility.

The substitution of a portion of cement with GGBS has been observed to enhance the compressive strength in diverse concrete blends. The strong reactivity of GGBS with cement is what causes the rise in strength.

P.Chandru et al(2016)

Research on the partial replacement of the traditional ingredients of concrete by two chosen waste materials is the result of the building industry’s growing look for sustainable and ecologically aware based resources.

The effectiveness of the concrete improves with a higher proportion of GGBS replacing cement as evidenced by the results of the slump cone test;

The fineness modulus of the GGBS is lesser than so as to of cement based materials, making the concrete denser and giving the specimens smooth finishes.

Christina Mary V (2015)

This study compares the “strength and durability” property of M40-grade concrete with ordinary concrete, focusing on the results of using artificial sand instead of natural with Msand at 50% and cement with GGBS at 10%, 20%, 30%, 40%, and 50%.

a) The maximum compressive strength at all testing ages was found at (M1) 10% Ggbs and 50% M sand optimum replacement, which translates to increases of 10.25%, 6.12%, and 5.66% over the conventional concrete’s compressive strengths after 14, 28, and 56 days. This information was based on the compressive strength results.

b) The split tensile strength data revealed that the HPC mix (M1), including 50% M sand and 10% GGBs, performed better than regular concrete. Compared to ordinary concrete, the high-performance concrete mix (M1) has a 0.85% greater value.

c) The findings for flexural strength show that high-performance concrete containing 30% GGBs and 50% M sand (M3) has the greatest flexural strength when compared to regular concrete. Flexural strength is improved by 75.36% more than with regular concrete.

Summary from literature review

Early on, the rapidity at which strength improves in slag-replaced concrete is minimal, but with adequate curing, the strength gains steadily and significantly.

When the cement replacement exceeds 50%, the compressive strength drops. The highest level of compressive strength is achieved when GGBFS is used to replace up to 45% of cement.

Due to the decreased relative density of slag, there is an increase in paste volume, leading to improved workability and a reduction in water demand when slag or slag cements are utilized. Because silica is included in GGBS, concrete mixes that contain a partial replacement of cement have shown better strength and durability across all classes. There is a 20% increase in strength after “7, 28, and 56 days” compared to ordinary concrete.

Objective and methodology

Objective

The primary objective of incorporating GGBS and Pond Ash in concrete is to enhance its performance, sustainability, and durability.

Workability and Durability

Examine the impact on the GGBS and Pond Ash, as well as their contribution to the long-term durability and resistance to aggressive chemical environments.

Environmental Impact Assessment

Quantify the reduction in carbon footprint and energy consumption associated with the incorporation of GGBS and Pond Ash in concrete through life cycle analysis.

Statistical Analysis

Employ statistical tools to analyze the data collected from tests and draw conclusions about the effectiveness of GGBS and Pond Ash in improving concrete properties.

By systematically addressing these objectives through a well-structured methodology, the study aims to provide valuable insights into the optimal use of GGBS and Pond Ash in concrete for sustainable and high-performance construction practices.

Methodology

Material collection and testing

General

Sand, coarse aggregate, GGBS, cement, and tests on the materials’ physical and chemical characteristics were conducted in a lab. In this chapter, the specifics of the materials, mix design, and replacement percentage are explained.

Material collection

Cement

The experimental study employed OPC of 53 grade, which confirms IS:12269; the parameters are listed in Table 4.1.

Procedure

Dry the bottle thoroughly and add kerosene to the point on the stem that is between 0 and 1 ml. As a starting point, note the liquid level in the bottle. With care to prevent splashing and cement adhesion, add a weighted amount of cement (more than 60 g) to the bottle until the kerosene level reaches around 22 ml. Expel air from the bottle by gently tilting it until no more air bubbles are visible on the surface.

Use this unit kg/m3

GGBS

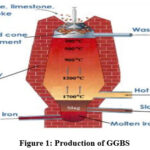

A by-product of the iron producing sector is the blast furnace slag. The furnace is fed with iron ore, coke and limestone, and the molten slag that is produced past the melting point of iron at a temperature of roughly 1500o C to 1600o C.

Compared to the energy required to produce Portland cement, not much more energy is needed to produce GGBS.

Test for specific gravity in GGBS

The traditional method for determining specific gravity involves dividing the weight of a specified volume of a substance by the mass of the same volume of kerosene. For the specific gravity of cement must be found.

Procedure

After properly drying the bottle, fill it with kerosene to a stem point that is between zero and one milliliter. Note the first reading of the liquid level in the bottle.

Physical Properties of GGBS

Table 1 Physical Properties of GGB

The following list contains the chemical attributes of GGBS that were purchased from GGBS manufacturing company.

Table 2: Chemical Properties of GGBS

|

S.NO

|

CHARACTERSTICS

|

TEST RESULTS

|

|

1

|

Magnesia Content (%)

|

7.73

|

|

2

|

Sulphur(%)

|

0.50

|

|

3

|

Sulphide Content(%)

|

0.38

|

|

4

|

Loss on Ignition(%)

|

0.26

|

|

5

|

Manganese Content(%)

|

0.12

|

|

6

|

Chloride Content(%)

|

0.009

|

|

7

|

Moisture Content(%)

|

0.10

|

Table 3: Evaluating the Physical Characteristics of Cement and GGBS.

|

S.NO

|

Properties

|

Cement

|

GGBS

|

|

1

|

Specific gravity

|

3.22

|

2.98

|

|

2

|

Bulk unit Weight

|

1400kg/m3

|

1454.5kg/m3

|

|

3

|

Fineness

|

4.2%

|

2.33%

|

|

4

|

Consistency

|

24%

|

31%

|

|

5

|

Initial setting time

|

33mins

|

32mins

|

|

6

|

Final setting time

|

600 mins

|

580 mins

|

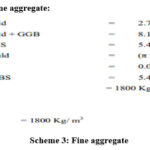

Fine aggregate

You might use river sand or shattered stones. Coarser sand may be chosen in High Performance Concrete as it uses less water than finer sand, especially when the concrete contains a larger percentage of fine particles from mineral admixtures such fly ash and cement.

Pond Ash

Pond ash, either totally or partially replace natural sand. Researchers have a social duty to promote the make use of this kind of waste industrial material as a component of concrete to address ecological, environmental, and disposal issues; additionally, by supporting the 3Rs (Reduce, Reuse, and Recycle), they can help to promote sustainable building practises.

Table 4 Chemical Composition of Pond Ash

|

S.No

|

Constituents

|

Percentage

|

Constituents

|

Percentage

|

Constituents

|

Percentage

|

|

1

|

SiO2

|

57.80

|

P2O5

|

0.19

|

Na2

|

0.16

|

|

2

|

Al2O3

|

25.10

|

SO3

|

0.28

|

TiO2

|

1.65

|

|

3

|

Fe2O3

|

08.83

|

K2O

|

0.82

|

Carbon

|

4.10

|

|

4

|

MgO

|

00.84

|

CaO

|

1.14

|

Volatile

Matter

|

0.14

|

Specific gravity test on POND ASH

Table 5: Comparison of Physical Properties of Fine aggregate and Pond Ash

|

S.No

|

Properties

|

Fine Aggregate

|

Pond Ash

|

|

1

|

Specific gravity

|

2.64

|

1.97

|

|

2

|

Bulk Unit weight

|

1800kg/m3

|

879kg/m3

|

|

3

|

Fineness modulus

|

2.27

|

2.39

|

Coarse aggregate

The most durable and least permeable part of concrete is the coarse aggregate. In cement concrete, there is a weak interface between the aggregate surface and cement matrix, and the coarse aggregate add to the material’s heterogeneity. This lessens the strength of cement concrete by tightening the transition zone and capping.

Specific gravity of coarse aggregate

Chemical admixtures

You might use broken stones or river sand. Coarser sand may be chosen in High Performance Concrete as it uses less water than finer sand, especially when the concrete contains a larger percentage of fine particles from mineral admixtures such fly ash and cement.

Air entraining agents,

Super plasticizers,

Retarders and

Plasticizers

Mix design and mix proportions

In order to make concrete with the required strength and durability at the lowest possible cost, Mix design involves selecting suitable components for concrete and determining their respective proportions. Indian Standard, based on 10262-2009, was utilised for this inquiry.

Mix design

In accordance with Indian Standard IS 10262: 2009, mix designs were created for M 35 grade.

Water: Cement : Fine aggregate : Coarse aggregate 0.45 : 1 : 1.89 : 3.86

Mix proportions

Concrete test specimens were cast by altering the percentage of GGBS from 0 to 40% of cement and modifying the pond ash from 0 to 20% of river sand in order to quantify the impacts of GGBS and pond ash in partially substituting cement and fine aggregate, respectively.

Table 6: Mix proportions for various Mixes.

|

Mix Name

|

GGBS

|

CEMENT

|

POND ASH

|

F.A

|

|

Conv.Mix

|

0

|

100

|

0

|

10

|

|

Mix1

|

10

|

90

|

10

|

90

|

|

Mix2

|

20

|

80

|

10

|

90

|

|

Mix3

|

30

|

70

|

10

|

90

|

|

Mix4

|

40

|

60

|

10

|

90

|

|

Mix5

|

10

|

90

|

20

|

80

|

|

Mix6

|

20

|

80

|

20

|

80

|

|

Mix7

|

30

|

70

|

20

|

80

|

|

Mix8

|

40

|

60

|

20

|

80

|

Experimental study and investigation

General

The test specimens were cast in 150mm steel cube and 150x300mm steel cylinder moulds.A plain concrete beam measuring 100x100x500 mm was cast for various GGBS and Pond Ash mix ratios. The following chapter contains a table of the outcomes.

Test on fresh and hardened concrete

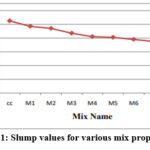

Slump Test

To assess the workability of concrete, employ the slump test. The metallic mold utilized for the slump test resembles a cone frustum, with internal dimensions measuring 20 cm for the bottom diameter, 10 cm for the top diameter, and 30 cm for the height.

Table 7: Slump values of Fresh Concrete.

|

S.NO

|

Mix Name

|

GGBS

|

POND ASH

|

Slump value

|

Degree workability

|

|

1

|

Conv.Mix

|

0

|

0

|

105

|

High

|

|

2

|

Mix1

|

10

|

10

|

97

|

Medium

|

|

3

|

Mix2

|

20

|

10

|

94

|

Medium

|

|

4

|

Mix3

|

30

|

10

|

87

|

Medium

|

|

5

|

Mix4

|

40

|

10

|

82

|

Medium

|

|

6

|

Mix5

|

10

|

20

|

81

|

Medium

|

|

7

|

Mix6

|

20

|

20

|

78

|

Medium

|

|

8

|

Mix7

|

30

|

20

|

75

|

Low

|

|

9

|

Mix8

|

40

|

20

|

69

|

low

|

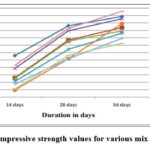

Compressive Strength Test

The trial specimens are cast in 150mm steel cube and 150x300mm steel cylinder molds. The trial cube specimens are created as soon as possible later than mixing and in a manner that results in complete compaction of the concrete without segregation or undue laitance. The mold is filled with layers of concrete that are each about 5 cm thick. Either by vibration or by hand, each layer is compacted. Using a trowel, the exterior of the concrete is raised to the over and done with the top of the mold after the top layer has been compressed. Concrete cubes are evaluated in compression testing equipment after adequate curing.

Table 8: Compressive Strength Test

|

Mix Name

|

GGBS

|

POND ASH

|

14 days compressive strength N/mm2

|

28 days compressive strength

N/mm2

|

56 days compressive strength

N/mm2

|

|

Conv.Mix

|

0

|

0

|

33.96

|

44.04

|

47

|

|

Mix1

|

10

|

10

|

26.54

|

39.20

|

.16

|

|

Mix2

|

20

|

10

|

26.30

|

38.84

|

42.29

|

|

Mix3

|

30

|

10

|

29.65

|

42.35

|

46.29

|

|

Mix4

|

40

|

10

|

25.28

|

36.12

|

46.41

|

|

Mix5

|

10

|

20

|

22.38

|

32.93

|

41.56

|

|

Mix6

|

20

|

20

|

24.38

|

32.92

|

39.80

|

|

Mix7

|

30

|

20

|

30.72

|

43.18

|

48.91

|

|

Mix8

|

40

|

20

|

22.79

|

34.02

|

38.10

|

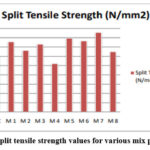

Split Tensile Strength

Following 28 days of water curing, split tensile strength tests were performed on cylindrical test specimens that were cast with dimensions of 150 mm in height and diameter. This method was used to indirectly quantify the tension in the concrete.

Table 9: Split Tensile Strength

|

Mix Name

|

GGBS %

|

POND ASH%

|

Split Tensile Strength N/mm2

|

|

Conv.Mix

|

0

|

0

|

3.08

|

|

Mix1

|

10

|

10

|

3.78

|

|

Mix2

|

20

|

10

|

3.31

|

|

Mix3

|

30

|

10

|

3.65

|

|

Mix4

|

40

|

10

|

2.60

|

|

Mix5

|

10

|

20

|

3.98

|

|

Mix6

|

20

|

20

|

3.83

|

|

Mix7

|

30

|

20

|

4.28

|

|

Mix8

|

40

|

20

|

3.24

|

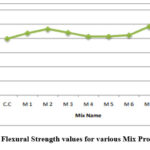

Flexural Strength

The flexural strength of a concrete prism of 100 mm by 100 mm by 500 mm will be computed following a 28-day water curing period.

Table 10: Flexural Strength.

|

S.NO

|

Mix Name

|

GGBS %

|

POND ASH%

|

Flexural strength N/mm2

|

|

1

|

Conv.Mix

|

0

|

0

|

7.942

|

|

2

|

Mix1

|

10

|

10

|

8.73

|

|

3

|

Mix2

|

20

|

10

|

9.31

|

|

4

|

Mix3

|

30

|

10

|

8.80

|

|

5

|

Mix4

|

40

|

10

|

8.25

|

|

6

|

Mix5

|

10

|

20

|

8.26

|

|

7

|

Mix6

|

20

|

20

|

8.44

|

|

8

|

Mix7

|

30

|

20

|

9.65

|

|

9

|

Mix8

|

40

|

20

|

8.45

|

Durability Test

The best mix for concrete durability with acid and sulphate is evaluated. The M7 mix is observed as the ideal mix based on the findings of the compressive strength test and the flexural strength test. Therefore, the mix M7 is chosen for additional durability research.

Attack by acid on the optimized mix

In this test, containers holding 3.5% H2SO4 and 3.5% HCl are filled with concrete cubes. The cubes are removed and left outside for another day after one day. The cube is now weighed at every stage of the cycle. The cubes go through the identical testing procedure 14 times over. After that, the cubes are tested in the CTM, where it is shown that their strength has decreased in comparison to the specimens that were not exposed.

Table 11: Compressive Strength of Mixes after HCl Exposure

|

S.NO

|

Mix Name

|

Weight before Exposure

|

Weight after Exposure

|

% change

|

Strength after Exposure N/mm2

|

% change

|

|

1

|

C.C

|

8.69

|

8.65

|

.45

|

41.57

|

5.95

|

|

2

|

M7

|

8.46

|

8.44

|

.24

|

42.09

|

2.59

|

Table 12: Compressive Strength of Mixes after H2SO4 Exposure Sulphate attack on Optimized Mix

|

S.NO

|

Mix Name

|

Weight before Exposure

|

Weight after Exposure

|

% change

|

Strength after Exposure N/mm2

|

% change

|

|

1

|

C.C

|

8.75

|

8.72

|

0.54

|

41.17

|

6.95

|

|

2

|

M7

|

8.45

|

8.43

|

0.26

|

41

|

5.31

|

Table 13: Compressive Strength of Mixes after MgSO4 Exposure.

|

S.NO

|

Mix Name

|

Weight before Exposure

|

Weight after Exposure

|

% change

|

Strength after Exposure N/mm2

|

% change

|

|

1

|

C.C

|

8.62

|

8.56

|

0.85

|

42.10

|

4.60

|

|

2

|

M7

|

8.55

|

8.49

|

0.64

|

41.68

|

3.59

|

Results and discussions

After 14-day duration, the compressive strength of all mix variations decreases by a certain percentage in comparison to standard concrete. The flexural strength of a concrete prism measuring 100 mm by 100 mm by 500 mm will be calculated following a 28-day water curing period. In contrast to regular concrete, the compressive strength of all mixes, except for M7, experiences a reduction by a certain percentage at 14 days.

Day 28 marks the achievement of the desired compressive strength for Mix M7 (30% GGBS and 20% pond ash), and at day 56, it exceeds ordinary concrete’s compressive strength.

Every blend has a somewhat greater flexural strength (%) in comparison to an average mix. Mix M7 has the maximum flexural strength.

Slump value decreases as GGBS and pond ash levels in concrete rise.

When exposed to acid (HCl) assault, the enhanced concrete mix performed better in terms of durability than the control concrete. The optimised mix’s weight drops by just 2.59% after 14 straight cycles, whereas the control mix’s weight drops by 5.95%.

Under acid (H2SO4) assault, the optimised concrete mix performed better in terms of durability than the control concrete. The mass of the optimized mix decreases by 5.31% after 14 successive cycles, whereas the mass of the control mix decreases by 6.95%.

When exposed to a 10% MgSO4 solution, the optimised concrete mix performed better in terms of durability. The control mix experiences a 4.60% reduction in weight.after 14 straight wet and dry cycles, whereas the weight of the optimised mix drops by just 3.59%.

In order to maintain the mechanical properties of concrete (“compressive strength, split tensile strength, and durability”) and maintain workability, it is desirable to replace 30% of GGBS with cement and 20% of fine aggregate with pond ash.

Conclusions

This study compares the usage of GGBS and pond ash to make environmentally friendly concrete. The important findings from the study are listed below.

Mix M7 exhibits outstanding compressive strength progression, showcasing impressive results of 30.72 N/mm² at 14 days, followed by significant enhancement to 43.18 N/mm² at 28 days, and a robust 48.91 N/mm² at 56 days, making it a highly durable and high-performance concrete mix. In the study comparing conventional mix and study mix (M1 to M8), the M7 mix exhibited a 28-day split tensile strength of 4.28 N/mm² and a flexural strength of 9.657 N/mm². Due to the low density of pond ash, the weight of the specimens decreased as the proportion of replacement of pond ash increased.

At 14 and 28 days after curing, concrete blend compressive strength is seen to be declining. The mixes’ compressive strength increases after 56 days.

Due to the addition of pond ash and GGBS, the split tensile strength and flexural strength of the optimized mix also rise at 28-day testing.

The improved concrete mix outperformed the control concrete in terms of durability when exposed to HCl, H2SO4, andMgSO4 solutions.

Using 30% GGBS and 20% pond ash in place of cement and fine aggregate, respectively.

Acknowledgement

The author would like to express their gratitude towards Tamilnadu College of Engineering, Coimbatore, Tamilnadu, India. For providing the necessary infrastructure to carry out this work successfully.

Conflicts of interest

No conflict of interest in this manuscript.

Funding Sources

There are no funding sources

References

- Abdulhameed U.A., K.A. Baharudin (2012),Properties of Concrete Using Tanjung Bin Power Plant Coal Bottom Ash and Fly Ash,” International Journal of Sustainable Construction Engineering and Technology (ISSN:

2180-3242), Vol. 3, Issue 2. - Aggarwal Y., Siddique R. (2014). “Strength, Durability, and Microstructural Properties of Concrete Made with Used Foundry Sand,” ConstructionBuild Master, 25, pp. 1916–1925.

CrossRef - Aggarwal Y, Siddique R (2014),Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates,” Construction and Building Materials, volume 54, pages 210–223.

CrossRef - Chandak, R., Atul Dubey, and R.K. Yadav (2012) “Effect of blast furnace slag powder on compressive strength of concrete “. International Journal of Innovative Technology and Exploring Engineering (IJITEE)ISSN: 2278-3075, Volume-2, Issue-4.

- IS 383 (1970), ‘Specifications for coarse and fine aggregates from natural sources for concrete’ Second revision,Bureau of Indian Standards,New Delhi [5] IS: 456-2000, ‘Indian Standard Code for Practice for Plain and Reinforced Concrete’ Bureau of Indian Standards, New Delhi, India [6] IS: 516-1959, ‘Indian Standard Code for Practice: Methods of Test for Strength of Concrete’ Bureau of Indian Standards, New Delhi, India

- IS: 10262-2009 ‘Recommended Guidelines for Concrete Mix Design’ Bureau of Indian Standards, New Delhi, India.

- IS: 12269-1987 ‘Specifications for 53-Grade Portland Cement’ Bureau of Indian Standards, New Delhi, India.

- Jumah Jessica Jaleel V. and Maya T.M. (2015), ‘Influence of Metakaolin on Concrete Containing Bottom Ash as Fine Aggregate’ International Journal of Research in Advent Technology (E-ISSN: 2321-9637), pp. 41–46.

- Kim H.K. and Lee H.K. (2011), ‘Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete’ Construction and Building Materials 25 (2011), pp. 1115–1122

CrossRef - Mohd Syahrul Hisyam bin Mohd Sani, Fadhluhartini bt Muftah, and Zulkifli Muda (2010), ‘The Properties of Special Concrete Using Washed Bottom Ash (WBA) as Partial Sand Replacement’ International Journal of Sustainable Construction Engineering & Technology, Vol. 1, No. 2, December 2010, pp. 65–76.

- Remya Raju, Mathews Paul K., and Aboobacker K.A. (2014),’strength performance of concrete using bottom ash as fine aggregate’, International Journal of Research in Engineering & Technology, Vol. 2, Issue 9, September 2014, pp. 111–122.

- Soman K., Divya Sasi, Abubaker K.A. (2014), ‘Strength properties of concrete with partial replacement of sand by bottom ash’ International Journal of Innovative Research in Advanced Engineering, Volume 1, Issue 7 (August 2014), pp. 223-227.

- M.S. Shetty, S.Chand (2010), ‘Concrete technology, theory, and practice’ Tata McGrah Hill Company Ltd., New Delhi

- Vikas R. Nadig, Sanjith J., Ranjith A., and Kiran B. M. ‘(2015),’Bottom Ash as Partial Sand Replacement in Concrete: A Review’, IOSR Journal of Mechanical and Civil Engineering, Volume 12, Issue2, Ver. 6 Mar-Apr. 2015), p. 148–151.

- Edem Baite , Adamah Messan , Kinda Hannawi , François Tsobnang , William Prince(2016) ‘Physical and transfer properties of mortar containing coal bottom ash aggregates from Tefereyre’ Construction and Building Materials 125 , pp. 919–926.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.

, M. Seethapathi1*

, M. Seethapathi1* and K. Mohan Das2

and K. Mohan Das2

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal