Tensile Properties and Fracture Morphology of Polyethylene Terephthalate Mixed Rice Starch Particle Based Blend Composites

Sumarji , Mochamad Gerindo Dwi Aqsho, Hari Arbiantara Basuki

, Mochamad Gerindo Dwi Aqsho, Hari Arbiantara Basuki , Mochamad Asrofi*

, Mochamad Asrofi*

Department of Mechanical Engineering, University of Jember, Kampus Tegalboto, Jember 68121, East Java, Indonesia

Corresponding Author Email: asrofi.teknik@unej.ac.id

DOI : http://dx.doi.org/10.13005/msri/170107

Article Publishing History

Article Received on : 02 April 2020

Article Accepted on : 30 April 2020

Article Published : 30 Apr 2020

Plagiarism Check: Yes

Reviewed by: Amin Bahrami

Second Review by: Jawad Kadhim

Final Approval by: Sameena Mehtab

Article Metrics

ABSTRACT:

This study examines the effect of addition rice starch particle (RSP) in Polyethylene terephthalate (PET) based blend composites. The concentration of RSP in PET was varied at 0, 5, 10, 15 and 20 wt% with fixed percentage of sorbitol for 2 ml. The blend composites were produced by solution mixing method. All samples were tested by tensile and morphological observation after tensile test. The tensile test proves that the addition of RSP in PET increased tensile strength of blend composites. The maximum tensile strength was in 15 wt% RSP in PET for 9.79 MPa. Optical microscope displays minimum porosity with good fusion between RSP and PET. The addition of starch in polymer is suggested to reduce the percentage of using non-biodegradable polymer plastic. This research is important due to the development of biodegradable polymer.

KEYWORDS:

Blend Composites; Rice Starch Particle; Polyethylene Terephthalate; Tensile Properties; Fracture Morphology

Copy the following to cite this article:

Sumarji, Aqsho M. G. D, Basuki H. A, Asrofi M. Tensile Properties and Fracture Morphology of Polyethylene Terephthalate Mixed Rice Starch Particle Based Blend Composites. Mat. Sci. Res. India; 17(1).

|

Copy the following to cite this URL:

Sumarji, Aqsho M. G. D, Basuki H. A, Asrofi M. Tensile Properties and Fracture Morphology of Polyethylene Terephthalate Mixed Rice Starch Particle Based Blend Composites. Mat. Sci. Res. India; 17(1). Available from: https://bit.ly/2W4AhJG

|

Introduction

Plastic is a kind of synthetic polymer that is widely used for daily human life. The application of plastic almost in every product such as packaging, automotive component, kitchen equipment and children’s toys.1-4 Various advantages possessed by the plastic, i.e. lightweight but strong, transparent, flexible, waterproof and cheap. However, the weakness of plastic is non-biodegradable in environment. Plastics often cause environmental pollution, flooding and air pollution.

In the past ten years, several researchers have attempted to make a breakthrough by utilizing biopolymers as biodegradation agents.5-8 For example, previous research reported on biocomposites from environmentally friendly starch. The biocomposite was made with 100% natural components, namely starch and natural fiber. They reported that the biocomposite was 100% degraded within one month.9-10 Even so, the nature of biocomposites has disadvantage such as not resistant to water and low mechanical properties.11-13 Therefore, a quite appropriate solution is to mix thermoplastics with starch. According to previous researches, the benefits obtained from mixing starch and thermoplastics include: reducing the use of synthetic plastics, environmentally friendly due to able to degraded by the environment, low production costs.4

The mixture of thermoplastic and starch has become a trend in the last five years. This is evidenced by the latest findings from Nguyen et al. (2019) about the addition of starch in low density polyethylene. They report that the addition of starch into thermoplastics increased the biodegradation rate and mechanical properties.14

Starch is a biopolymer consisting of amylose and amylopectin fractions. Both of these fractions have a role in mechanical properties. According to previous studies, high amylose fraction improved the tensile strength of starch films.15-16 It was indicated that the bonds of amylose polymer chains were more flexible than amylopectin.

Mixing of starch with thermoplastic polymers has been carried out by several researchers. They used a casting method to cast blend composite films. The addition of plasticizers such as glycerol produces a flexible blend composite (not brittle) compared to without the addition of glycerol. This is due to the role of glycerol as an initiator of polymer chain flexibility.17-19

Mixing of Polyvinyl alcohol (PVA) and yam bean starch has also been done by Asrofi et al. (2019). They reported that PVA and starch showed good mixing with the addition of glycerol as a plasticizer agent.4 In his study, starch successfully became a biodegradation agent and improved mechanical properties. The selection of rice starch in this study based on the amylose content in this material around 30%. This value is higher than other starches such as cassava, potatoes, yam bean, purple yam and others. High amylose content resulting in ductile properties to the blend composites film. It was also explained in previous studies that the high amylose increased the tensile strength of blend composites.15

In addition, the reason for choosing this object is due to the availability of rice starch in Jember, Indonesia is quite abundant. In that sense, using of rice starch as a reinforcement and biodegradation agent in a blend composites with PET matrix is a new innovation. The hydrophilic nature of rice starch is able to damage the bonding chain between synthetic plastic and starch. The breakdown of these bonds resulting synthetic plastic destroyed in the environment. Therefore, from some of our reviews, there are no studies reported about the mixing of rice starch with PET based blend composite. The blend composites were tested by the tensile test and observed using fracture morphology after tensile test.

Materials and Methods

Materials

Raw rice was purchased from Tanjung local market, Jember. Polyethylene terephthalate (PET) (Jade brand polyester chips CZ-302) was purchased from Jiangsu Xingye Plastic co. ltd. Sorbitol as plasticizer (90% purity) was supplied from Aneka chemical shop, Jember.

Preparation of rice starch particle (RSP)

Raw rice was washed and cleaned with water to remove impurities. The raw rice was blended with water (wet blending) at 10000 rpm for 10 min as reported by a previous study.20 The rice porridge suspension was held in a container and deposited for one day at room temperature. The precipitated starch was separated with water and then dried in an electric stove (under Maspion brand, Model 302) at 50oC for 2 h to obtain the dried starch. The starch was blended at 10000 rpm for 5 min and filtered using a 62T screen filter (mesh 155) to make homogeneous distribution size of RSP.

Fabrication of blend composites

The solution mixing (blending) method was used to fabricate the blend composites. Firstly, 60 grams of PET pellets were placed on the Teflon chamber before the melting process. Then, PET was melted by using an electric stove (S302 Maspion brand) by giving heat 250 oC for 20-25 min. Secondly, after PET melts, sorbitol was added as much as 2 ml. The mixture was stirred manually for 3 min with a wooden spoon until homogeneous mixing. Thirdly, RSP was included in the mixture with varying concentrations namely 0, 5, 10, 15 and 20 wt%. They were stirred evenly for 2 min. Fourth, the blend composite mixtures were poured into a mold (dimension: 10 cm × 10 cm), and then they were dried at room temperature for 24 h. The blend composite samples were deposited in a plastic sealer before testing.

Characterization

The tensile test was carried out by Universal Testing Machine HT-2404. The samples were formed by following ASTM D882 standard.21 The test was carried out in room temperature condition. Three samples in each variation were prepared for testing. After tensile test, all fractured samples were observed by USB digital microscope (PC endosc-te07). The magnification from 20X to 800X with 8LED 3D zoom. The observation was conducted at room temperature.

Results and Discussion

Tensile Properties

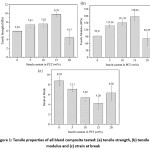

There are three samples for each variation of RSP addition in PET. This testing aims to determine the capacity of the sample receive the tensile load. Figure 1 shows the tensile strength of all samples tested.

It can be seen that PET with 0wt% RSP (unfilled) has 5.94 MPa for tensile strength. This value is different with 5, 10, 15 and 20 wt% RSP in PET. This case is indicated by unpresented of RSP in PET. The tensile strength of pure PET in this study was lower than native low-density polyethylene as the previous report.22 The addition of RSP in PET improved the tensile strength. It was proved by the addition 5, 10, and 15 wt% for 7.41, 7.62, and 9.79 MPa, respectively. It is due to the strong interaction’s hydrogen bonds between two phases of PET and RSP.14, 23

However, 20wt% RSP in PET, tensile strength was reduced from 9.79 to 4.41 MPa. This is due to the presence of voids in this sample. This phenomenon is synchronous with the digital microscope image observation in Figure 2e. The changing phenomenon of tensile strength tendency is supported by tensile modulus (Figure 1b) and strain at break (Figure 1c). The addition of RSP in PET increased tensile modulus and decreased strain at break. It can be concluded, the presence of RSP in PET resulting in brittle fracture.12 A similar report was studied by Nguyen et al. (2016) and Beg et al. (2015).14, 22

Figure 1: Tensile properties of all blend composite tested: (a) tensile strength, (b) tensile modulus and (c) strain at break

Morphological in Fracture Section

Figure 2 shows the morphological fracture section of all blend composites tested by USB digital microscope. Figure 2a shows the fracture of pure PET sample. It can be seen that PET has a smooth surface and did not show any RSP in this section. This is indicated by good dissolution of PET during melting and mixing process.22, 24 Different phenomena are shown by PET samples filled by RSP. The addition of 5 wt% in PET (Figure 2b) shows morphological changes in the form of brownish color with some voids formed. Besides voids, there are RSP particles are not perfectly gelatinized. This phenomenon is similar as shown by the 10 wt% in PET sample (Figure 2c). However, this sample showed an increase in mechanical properties due to the good mixing between RSP and PET.14

At 15 wt% RSP in PET (Figure 2d), the fracture morphology showed no void formed. However, the digital microscope shows some RSP is not perfectly gelatinized in PET. The mixture between RSP and PET is almost homogeneous which is indicated by the perfect brown mixture color. The homogeneous mixture produces a good hydrogen bond between RSP and PET.23-24 This is consistent with the results of maximum tensile strength in this sample.

Figure 2: Fracture morphology of all sample tested: (a) pure PET, (b) 5wt%, (c) 10wt%, (d) 15wt%, (e) 20wt% in PET

Meanwhile, 20 wt% in PET sample (Figure 2e) showed a fairly large void. This affected in reduced tensile strength of the blend composites. It can be concluded that the formation of voids can reduce the transfer of stress to the matrix. This phenomenon is similar to previously reported about thermoplastic cassava starch reinforced kenaf fiber.25

Conclusion

The addition of RSP by 5 – 15 wt% in PET increases the tensile strength of blend composites. The maximum tensile strength was 9.79 MPa for 15 wt% RSP in PET. This result is supported by fracture morphology which indicated by good mixing between RSP and PET. Meanwhile, minimum void, perfectly gelatinized of RSP, hydrogen bonding between RSP and PET also become an important factor in increasing the tensile properties. The presence of a starch particle in polymer becomes new material as reinforcing agent. The addition of starch in synthetic polymer probably used as a potential application in the field of packaging application.

Acknowledgments

The authors are thankful to the University of Jember and Ministry of Research, Technology and Higher Education Indonesia for supporting this research.

Funding

The authors are thankful to the University of Jember and Ministry of Research, Technology and Higher Education Indonesia for supporting this research.

Conflict of Interest

The authors declare no conflict of interest.

References

- S. Tabasum, M. Younas, M. A. Zaeem, I. Majeed, M. Majeed, A. Noreen, M. N. Iqbal, K. M. Zia, A review on blending of corn starch with natural and synthetic polymers, and inorganic nanoparticles with mathematical modeling. Int. J. Biol. Macromol. 122, 969-996 (2019).

- A. M. N. Maisara, R. A. Ilyas, S. M. Sapuan, M. R. M. Huzaifah, N. Mohd Nurazzi, S. O. A. Saiful Azry, Effect of fibre length and sea water treatment on mechanical properties of sugar palm fibre reinforced unsaturated polyester composites. Int. J. Recent Technol. Eng. 8, 510-514 (2019).

- S. Wahono, A. Irwan, E. Syafri, M. Asrofi, Preparation and characterization of ramie cellulose nanofibers/CaCO3 unsaturated polyester resin composites. ARPN J. Eng. App. Sci. 13, 746-751 (2018).

- M. Asrofi, D. Dwilaksana, H. Abral, R. Fajrul, Tensile, thermal, and moisture absorption properties of polyvinyl alcohol (PVA)/bengkuang (pachyrhizuserosus) starch blend films. Mater. Sci. Res. India. 16, 70-75 (2019).

- S. S. A. Osman Al Edrus, P. M. Tahir, C. T. Guan, L. S. Hua, J. A. Halip, R. A. Ilyas, S. M. Sapuan, Degradation of medium density fibre board and particleboard mechanical performance after exposed to different environmental condition. Int. J. Recent Technol. Eng. 8, 528-532 (2019).

- H. Abral, M. H. Dalimunthe, J. Hartono, R. P. Efendi, M. Asrofi, E. Sugiarti, S. M. Sapuan, J. W. Park, H. J. Kim, Characterization of tapioca starch biopolymer composites reinforced with micro scale water hyacinth fibers. Starch Starke. 70, 1700287 (2018).

- H. Abral, R. S. Satria, M. Mahardika, F. Hafizulhaq, J. Affi, M. Asrofi, D. Handayani, S. M. Sapuan, I. Stephane, E. Sugiarti, A. N. Muslimin, Comparative study of the physical and tensile properties of jicama (Pachyrhizus erosus) starch film prepared using three different methods. Starch‐Stärke. 71, 1800224 (2019).

- R. A. Ilyas, S. M. Sapuan, R. Ibrahim, H. Abral, M. R. Ishak, E. S. Zainudin, M. Asrofi, M. S. N. Atikah, M. R. M. Huzaifah, A. M. Radzi, A. M. N. Azammi, M. A. Shaharuzaman, N. M. Nurazzi, E. Syafri, N. H. Sari, M. N. F. Norrrahim, R. Jumaidin, Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: a comprehensive approach from macro to nano scale. J. Mater. Res. Technol. 8, 2753-2766 (2019).

- M. Mahardika, H. Abral, A. Kasim, S. Arief, F. Hafizulhaq, M. Asrofi, Properties of cellulose nanofiber/bengkoang starch bionanocomposites: Effect of fiber loading. LWT. 116, 108554 (2019).

- R. A. Ilyas, S. M. Sapuan, R. Ibrahim, H. Abral, M. R. Ishak, E. S. Zainudin, M. S. N. Atikah, N. M. Nurazzi, A. Atiqah, M. N. M. Ansari, E. Syafri, M. Asrofi, N. H. Sari, R. Jumaidin, Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 8, 4819-4830 (2019).

- M. Asrofi, H. Abral, A. Kasim, A. Pratoto, M. Mahardika, F. Hafizulhaq, Characterization of the sonicated yam bean starch bionanocomposites reinforced by nanocellulose water hyacinth fiber (WHF): The effect of various fiber loading. J. Eng. Sci. Technol. 13, 2700-2715 (2018).

- M. Asrofi, H. Abral, A. Kasim, A. Pratoto, M. Mahardika, F. Hafizulhaq, Mechanical properties of a water hyacinth nanofiber cellulose reinforced thermoplastic starch bionanocomposite: Effect of ultrasonic vibration during processing. Fibers. 6, 40 (2018).

- E. Syafri, S. Wahono, A. Irwan, M. Asrofi, N. H. Sari, A. Fudholi, Characterization and properties of cellulose microfibers from water hyacinth filled sago starch biocomposites. Int. J. Biol. Macromol. 137, 119-125 (2019).

- D. M. Nguyen, T. V. V. Do, A. C. Grillet, H. H. Thuc, C. N. H. Thuc, Biodegradability of polymer film based on low density polyethylene and cassava starch. Int. Biodeter. Biodegr. 115, 257-265 (2016).

- S. Mali, M. V. E. Grossmann, M. A. Garcı́a, M. N. Martino, N. E. Zaritzky, Mechanical and thermal properties of yam starch films. Food Hydrocoll. 19, 157-164 (2005).

- M. Asrofi, H. Abral, Y. K. Putra, S. M. Sapuan,bH. J. Kim, Effect of duration of sonication during gelatinization on properties of tapioca starch water hyacinth fiber biocomposite. Int. J. Biol. Macromol. 108, 167-176 (2018).

- F. J. Rodriguez-Gonzalez, B. A. Ramsay, B. D. Favis, Rheological and thermal properties of thermoplastic starch with high glycerol content. Carbohydr. Polym. 58, 139-147 (2004).

- D. Schlemmer, E. De Oliveira, M. J. Araújo Sales, Polystyrene/thermoplastic starch blends with different plasticizers: Preparation and thermal characterization. J. Therm. Anal. Calorim. 87, 635-638 (2007).

- M. A. Huneault, H. Li, Preparation and properties of extruded thermoplastic starch/polymer blends. J. Appl. Polym. Sci. 126, E96-E108 (2012).

- M. Asrofi, H. Abral, A. Kasim, A. Pratoto, Characterization of the microfibrillated cellulose from water hyacinth pulp after alkali treatment and wet blending. IOP Conf. Series: Mater. Sci. Eng. 204, 012018 (2017).

- ASTM D882-02, Standard test methods for tensile properties of thin plastic sheeting. Philadelphia, PA: American Society for Testing and Materials (2002).

- M. D. H. Beg, S. Kormin, M. Bijarimi, H. U. Zaman, Preparation and characterization of low density polyethylene/thermoplastic starch composites. Advan. Polym. Technol. 35, 1-9 (2015).

- H. Abral, G. J. Putra, M. Asrofi, J. W. Park, H. J. Kim, Effect of vibration duration of high ultrasound applied to bio-composite while gelatinized on its properties. Ultrasonic. Sonochem. 40, 697-702 (2018).

- Y. Chen, X. Cao, P. R. Chang, M. A. Huneault, Comparative study on the films of poly (vinyl alcohol)/pea starch nanocrystals and poly (vinyl alcohol)/native pea starch. Carbohydr. Polym. 73, 8-17 (2008).

- S. Y. Z. Zainuddin, I. Ahmad, H. Kargarzadeh, I. Abdullah, A. Dufresne, Potential of using multiscale kenaf fibers as reinforcing filler in cassava starch-kenaf biocomposites. Carbohydr. Polym. 92, 2299-2305 (2013).

This work is licensed under a Creative Commons Attribution 4.0 International License.

, Mochamad Gerindo Dwi Aqsho, Hari Arbiantara Basuki

, Mochamad Gerindo Dwi Aqsho, Hari Arbiantara Basuki , Mochamad Asrofi*

, Mochamad Asrofi*

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal