Impact Strength Analysis of Polymer Composite Materials (PCM) Fiber Reinforced in the Fiberboat Application

Introduction

Mechanical property is one that represents the ability to accept loads/forces/energy. The mechanical properties of materials reflect the relationship between the load/force/energy received, and the reaction has given or the deformation that will occur. Therefore, the mechanical properties of materials are very important known because it will affect the quality of materials in accepting the force. Mechanical properties material consists of strength, hardness, elasticity, rigidity, plasticity, toughness, fatigue, and crawling. The composite material is a material that has a multi-phase system composed of reinforcing materials and matrix materials, as shown in Figure 1. Because composite materials have advantages in various ways, such as low density, high mechanical properties, performance comparable to metals, resistance to corrosion, and easy to fabricate.1 There are two types of composite materials, natural and synthetic matrices.2-10 And the Matrix divided into, including polymer, ceramic, and metal. Inside the composite material also has reinforcement in the form of fiber, sheet, particle reinforced.1,11

Polymer Composite Materials (PCM) Fiberglass-reinforced has proven advantages when applied in the marine environment. The benefits including lightweight, strong, easy to print, and cheap. Then, when compared to steel and aluminum materials, polymer composite materials (PCM) fiberglass-reinforced have a modulus of elasticity and low fatigue strength.12,13 Polymeric materials divided into two types; thermosets and thermoplastics.14,15 In the marine industry, the application of polymer composite materials (PCM) fiberglass-reinforced has been carried out by16-18 and in shipbuilding / even submarine.13,19-21

In marine, applications generally a low-cost and high-performance material choice required. Different when using materials such as carbon and aramid. Glass fiber material was chosen because it has low production costs with high performance. The material has been used in a variety of forms including, unidirectional tows, woven and stitched fabrics, and chopped random mats. Meanwhile, Polymer Composite Materials (PCM) Fiberglass-reinforced widely used as a substitute for carbon fiber and aramid. To improve the quality of the boat or even submarines made from fiberglass composite materials, researchers conducted studies on the variation of reinforcement and matrix to obtain the best mechanical, physical, and chemical properties.13,17-19,22-24 The results of fiberglass composite material proved to be able to replace carbon fiber and aramid when applied in the marine field.

Unsaturated polyester is one of the most widely used resin types in the marine industry, especially in Indonesia. The main advantage of this material, besides having low production costs, the material has unique chemical properties when applied in the marine industry. Coupled with the resin itself has a long shelf life. For this reason, polyesters are widely produced. Among the various types of polyester resins, the isophthalic variety offers the most attractive combination of mechanical strength and resistance to the marine environment. However, from a cost viewpoint, the orthophthalic variety holds attractions for the small boat industry.21

In this research, Hardener type MEPOXE (Methyl Ethyl Ketone Peroxide) and Poliester Yukalac-157® BTQN-EX as a matrix were used each materials are produced by PT KAWAGUCHI KIMIA INDONESIA and PT JUSTUS SAKTI RAYA respectively. Poliester Yukalac-157® BQTN-EX chose because it is specifically a manufacturing process of Fiber Reinforced Polymer systems (FRPs) with hand lay-up and spray molding. In general, this resin commonly used in the manufacture of fishing boats, bathtubs, building materials, and other FRP products. The material properties present in this resin are as shown in Table 1.

Table 1: Properties of unsaturated Polyester Resins YUKALAC-157® BQTN-EX:

|

Item

|

Score

|

Unit

|

Note

|

|

Spesific Grafity

|

|

|

|

|

Hardness

|

40

|

–

|

Barcol/GYZJ 934-1

|

|

Water Absorption ()

|

0.188

|

%

|

24 Hours

|

|

Water Absorption ()

Flexural Strength

|

0.466

|

%

|

7 Days

|

|

9.4

|

|

|

|

Flexural Modulus

|

300

|

|

|

|

Range Power

|

5.5

|

|

|

|

Modulus Young

|

1.18

|

GPa

|

|

|

Store Life At

|

Less than 6

|

Months

|

|

The composite material used most frequently in Indonesia has been E-glass type in a matrix of polyester or epoxy resin. This type less strong and slightly less stiff than the other commonly available glass but is markedly cheaper, as shown in Table 2. In recent years, several other fibers have become available like carbon and aramid, but have been generally too expensive to apply in Indonesia.

Table 2: Properties of some commonly used reinforcing fibers

|

Fiber

|

Density

()

|

Tensile Strength

(GPa)

|

Young’s Modulus

(GPa)

|

Failure Strain

(%)

|

Relative Cost

|

|

E-glass

|

2.6

|

3.1-3.8

|

75-78

|

4.5-4.9

|

Low

|

|

S-glass

|

2.4

|

4.6-4.8

|

88-96

|

5.4-5.8

|

Medium

|

|

Aramid

|

1.4

|

3.6

|

41-186

|

2.9-8.7

|

Medium-High

|

|

Carbon

|

1.78

|

4.2-6.1

|

230-300

|

1.8-2.0

|

Medium-High

|

|

Structural steel

|

7.8

|

0.45-0.65

(0.35 yield)

|

2 at yield

1.8 at ultimate

|

|

High

25 at failure

|

In this research, used three types of E-glass; CSM 300 (Chopper Strand Mat 300), CSM 400 (Chopper Strand Mat 400), and WR 600 (Woven Roving 600) each produced by TAIWAN GLASS IND.CORP. with distributors PT JUSTUS KIMIARAYA as shown in Figure 2.

In general, this Fiber type commonly used in the manufacture of traditional boats, bathtubs, building materials, and other FRP products. The material properties present in this Fiber type are as shown in Table 3.

Table 3. Properties of Fiberglass

|

Item

|

Spesification

|

|

Weight (

|

Weidth ()

|

Long ()

|

|

Chopper Strand Mat 300

|

300

|

104

|

960

|

|

Chopper Strand Mat 400

|

400

|

104

|

640

|

|

Woven Roving 600

|

600

|

100

|

–

|

Furthermore, for Polymer Composite Materials (PCM) Fiberglass-reinforced have the strength following the needs in boat/ship manufacturing, The impact test is the kinetic energy needed to break the material. In boat/ship manufacturing, it is necessary to know the impact resistance.17

In Indonesia, the number of reinforcing layers used is six layers with a percentage composition of hardener weight 0.5 wt .-% for fiberboard building. In this study, the researcher wanted to determine the effect of adding and reducing layers and the percentage of reinforcement on the impact strength of Polymer Composite Materials (PCM) Fiberglass-reinforced.

Materials and Methods

Materials

The first research procedure was weighing and stirring the resin/epoxy material with a hardener. Furthermore, for polymer composite materials (PCM) fiberglass-reinforced variations, the amount of lamination used starts from layered layers to layers with CSM 300, CSM 450, and WR 600 compositions as calculated by Table 4 and variations in the use of epoxy resin plates and hardeners respectively. 99.5% -0.5% each. Then for other polymers composite materials (PCM) fiberglass-reinforced, five weight variations of the Epoxy Resins and Hardener matrix are used, as shown in Table 5 with the amount of reinforcement lamination used A3.

Table 4: Experimental design polymer composite materials (PCM) fiberglass-reinforced reinforcement variations with variations of the sample matrix B1

|

No.

|

Description

|

Lamination Arrangement

|

|

Sample

|

|

A1

|

A2

|

A3

|

A4

|

A5

|

|

1.

|

Order of layers:

|

|

|

|

|

|

|

1

|

CSM 300

|

CSM 300

|

CSM 300

|

CSM 300

|

CSM 300

|

|

2

|

WR 600

|

CSM 450

|

CSM 450

|

CSM 450

|

CSM 450

|

|

3

|

CSM 450

|

WR 600

|

WR 600

|

WR 600

|

WR 600

|

|

4

|

CSM 450

|

CSM 450

|

CSM 450

|

CSM 450

|

CSM 450

|

|

5

|

|

CSM 450

|

WR 600

|

WR 600

|

WR 600

|

|

6

|

|

|

CSM 450

|

CSM 300

|

CSM 300

|

|

7

|

|

|

|

CSM 450

|

WR 600

|

|

8

|

|

|

|

|

CSM 450

|

Table 5: Experimental designs polymer composite materials (PCM) fiberglass-reinforced matrix variation with variation reinforcement A3

|

No.

|

Description

|

Weight Percentage [wt.-%]

|

|

Sample

|

|

B1

|

B2

|

B3

|

B4

|

B5

|

|

1.

|

Lamination Order:

|

|

|

|

|

|

|

|

Epoxy Resins

|

99.5

|

99

|

98.5

|

98

|

97.5

|

|

|

Hardener

|

0.5

|

1

|

1.5

|

2

|

2.5

|

Methods

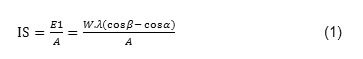

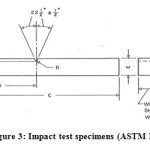

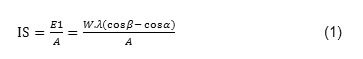

The impact tests were carried out on each specimen that has been synthesized by repeat the test three times. The impact strength of the material can be seen from the resistance of the material to the force applied suddenly. From the impact test, it can be obtained the impact strength of polymer composite materials (PCM) fiberglass-reinforced specimens made refer to ASTM D6110, as shown in Figure 3. Impact strength can result in using (1);

Where W is Work required to break the test object (kg m), λ is The length of the swinging arm (m), cos α is The initial angle of the pendulum, cos β is The final angle of the pendulum and A is The cross-sectional area below the notch (m2).

Results and Discussion

Impact testing is divided into two types of tests, namely Izod and Charpy. in this study using the Charpy method. The impact test specimens use a predetermined standard that is ASTM D6110, as shown in Figure 3. The results of the impact tests have been carried out on polymer composite materials (PCM) fiberglass-reinforced reinforcement variations, as shown in Table 6.

Table 6: Impact test results on variations in reinforcing polymer composite materials (PCM) fiberglass-reinforced

|

Sample

|

Impact Strength [MPa]

|

|

A1

|

366.297

|

|

A2

|

379.859

|

|

A3

|

396.756

|

|

A4

|

405.392

|

|

A5

|

413.712

|

Based on Table 6 the impact strength values obtained on polymer composite materials (PCM) fiberglass-reinforcedare equal to A1 = 366,297 MPa, A2 = 379,859 MPa, A3 = 396,756 MPa, A4 = 405,392 MPa and A5 = 413,712 MPa. These results indicate that, polymer composite materials (PCM) fiberglass-reinforced varies with reinforcement resulting in an impact value that increases with the addition of reinforcement to the material.

Based on Table 6 also, the impact strength value produced for each sample A1 to A5 has differences, ranging from 8 MPa to 16 MPa. The difference is influenced by differences in the type of amplifier added. For sample A1 and A2, the addition of CSM 450 amplifier type has a difference in impact strength of 13.562 MPa. Then for sample A2 and A3, it has the addition of the WR 600 type amplifier. So it has a difference in impact strength of 16.897 MPa. After that, for sample A3 and A4 have the addition of CSM 300 amplifier type. The results obtained from the addition of the amplifier type have an impact strength difference of 8.636 MPa. Finally, the sample A4 and A5 samples have WR 600 amplifier type addition. The results obtained from the addition of the amplifier type difference in impact strength value obtained is 8.320 MPa.

Then the impact test results of polymer composite materials (PCM) fiberglass-reinforced reinforcement variations, as shown in Figure 4. That figure appears that samples A1 to A5 have the same fracture characteristics while the fracture location is slightly different. The form of fracture in question is that there are residual fibers in the test sample. Because the polymer composite materials (PCM) fiberglass-reinforced has an inherent inhomogeneous and anisotropic structure coupled with the hardening process in the material because of by many factors. While the shape of the resulting fracture shows that the material is classified Brittle or Ductile.

After knowing the results of the impact test on polymer composite materials (PCM) fiberglass-reinforced reinforcement variations, then for the results obtained from the impact test varies matrix on polymer composite materials (PCM) fiberglass-reinforced, as shown in Table 7.

Table 7: Impact test results on variations in the matrix of polymer composite materials (PCM) fiberglass reinforced

|

Sample

|

Impact Strength [MPa]

|

|

B1

|

396.865

|

|

B2

|

400.890

|

|

B3

|

412.374

|

|

B4

|

416.487

|

|

B5

|

410.247

|

Based on Table 7 the impact strength values obtained on fiberglass-reinforced polymer composite material (PCM) are equal to B1 = 396.865 MPa, B2 = 400.890 MPa, B3 = 412.374 MPa, B4 = 416.487 MPa and B5 = 410.247 MPa. These results indicate that the polymer composite material (PCM) with a variety of fiberglass reinforced matrix produces an impact value that increases with the addition of the percentage of the weight of the matrix on the material. However, some samples produce a small impact strength when compared to the previous sample type.

Based on Table 7 also, the impact strength value produced for each sample B1 to B5 has differences, ranging from 4 MPa to 11 MPa. The smallest impact strength value is found in the sample B1 396.865 MPa. The results obtained because it has matrix weight of 0.5%. The greatest impact strength value is found in sample B4 416.487 MPa. The results obtained because it has a matrix weight of 2.0%. When viewed from the percentage of the given, B5 has the largest percentage of matrix weights. But the results obtained for B5 samples are smaller than B4 and B3 410,247 MPa.

Then the impact test results of polymer composite materials (PCM) fiberglass-reinforced reinforcement variations, as shown in Figure 5. That figure appears that samples B1 to B5 have the same fracture characteristics while the fracture location is slightly different. The form of fracture in question is that there are residual fibers in the sample. That is because the polymer composite materials (PCM) fiberglass-reinforced has an inherent inhomogeneous and anisotropic structure coupled with the hardening process in the material. The shape of the resulting fracture shows that the material is classified as Brittle or Ductile.

Conclusions

The results of impact testing of fiberglass reinforced polymer composite materials (PCM) with each reviewing the effect of reinforcement variations and matrix variations as fiberglass boat building materials, a conclusion is obtained that the variation of reinforcement and matrix variations affect the impact strength. The best value is obtained from the variation of polymer composite materials (PCM) fiberglass-reinforced on impact strength, namely the reinforcement of eight layers, with an impact strength 413,712 MPa. Then the best value of the variation of the polymer composite materials (PCM) fiberglass-reinforced strength on impact strength is the matrix content 2.0 wt .-%, with an impact strength 416,487 MPa.

Acknowledgements

This work was supported by the Directorate of Research Marine and Fisheries Polytechnic of Sorong and Ship Construction and Shipbuilding Laboratory Department of Shipping Engineering Surabaya Sepuluh Nopember Institute of Technology.

Conflict of Interest

The author(s) declare(s) that there is no conflict of interests regarding the publication of this article.

Funding Source

The authors are thankful to the Marine and Fisheries Polytechnic for supporting this research.

References

- Wang, R.-M., Zheng, S.-R., & Zheng, Y.-P. (2011): Polymer matrix composites and technology. Beijing: Woodhead Publishing Limited and Science PressLimited.

- Clareyna, E. D., & Mawarani, L. J. Pembuatan dan Karakteristik Komposit Polimer Berpenguat Bagasse. TEKNIK POMITS. 2. 2, 2337-3539 (2013).

- Elanchezhian, C., Vijaya Ramnath, B., Ramakrishnan, G., Rajendrakumar, M., Naveenkumar, V., & Saravanakumar, M. K. Review on mechanical properties of natural fiber composites. Selection and Peer-review under responsibility of International Conference on Processing of Materials, Minerals and Energy. 5, 1785–1790 (2018).

CrossRef

- Kumre, A., Rana, R., & Purohit, R. A Review on mechanical property ofsisal glass fiber reinforced polymer composites. Selection and peer-review under responsibility of Conference Committee Members of 5th International Conference of Bhopal. 4, 3466–3476 (2017).

CrossRef

- Minah, F. N., Astuti, S., & Rastini, E. K. KARAKTERISASI MATERIAL KOMPOSIT POLIMER POLISTYRENE DAN SERAT TEBU. INDUSTRI INOVATIF. 7. 1, 1-6 (2017).

- Widyatmaja, D. W., Raharjo, W. W., & Sukanto, H. PENGARUH SUHU PENCAMPURAN TERHADAP KEKUATAN TARIK DAN FRACTURE TOUGHNESS EPOXY RESIN – ORGANOCLAY MONTMORILLONITE NANOKOMPOSIT. MEKANIKA. 12. 2, 101-107 (2014).

- Thwe, M.M., Liao, K., Effects of environmental aging on the mechanical properties of bamboo-glass fiber reinforced polymer matrix hybrid composites. Composites: Part A. 33, 43 – 52 (2002).

CrossRef

- Senthilkumar, K., Saba, N., Rajini, N., Chandrasekar, M., Jawaid, M., Siengchin, S., Alotman, O.Y., Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review, Construction and Building Materials. 174, 713–729 (2018).

CrossRef

- Ray, K., Patra, H., Swain, A.K., Parida, B., Mahapatra, S., Sahu, A., Rana, S., Glass/jute/sisal fiber reinforced hybrid polypropylene polymer composites: Fabrication and analysis of mechanical and water absorption properties, Materials Today: Proceedings. xxxx, xxx, xxx (2020).

CrossRef

- Ansari, A.A., Dhakad, S.K., Agarwal, P., Investigation of mechanical properties of sisal fibre and human hair reinforced with epoxy resin hybrid polymer composite, Materials Today: Proceedings. xxxx. xxx, xxx (2020).

CrossRef

- Nayak, R. K., Mahato, K. K., & Ray, B. C. Water absorption behavior, mechanical and thermal properties of nano TiO2 enhanced glass fiber reinforced polymer composites. Composites: Part A. 90, 736–747 (2016).

CrossRef

- Naresh, K., Shankar, K., Rao, B., & Velmurugan, R. Effect of high strain rate on glass/carbon/hybridfiber reinforced epoxy laminated composites. Composites Part B. 100, 125-135 (2016).

CrossRef

- Wahrhaftig, A., Ribeiro, H., & Nogueira, A. Marine Composites Design and Performance. Woodhead Publishing, Sawston, Cambridge. 301-313 (2019).

CrossRef

- Dossou, G. K., Boumbimba, R. M., Bonfoh, N., Hernandez, S. G., Gonzalez, D. G., Gerard, P., et al. Innovative acrylic thermoplastic composites versus conventionalcomposites: improving the impact performances. Composite Structures. 217. 1, 1-13 (2019).

CrossRef

- Zainuddin, S., Hosur, M., Mohammed, A., Smith, E., & Jeelani, S. Lightweight Composite Structures in Transport, Design, Manufacturing, Analysis and Performance. Woodhead Publishing, Sawston, Cambridge. 166-187 (2016).

- Chalmers, D. The Potential for the Use of Composite Materials in Marine Structures. Marine Structures. 7, 441-456 (1994).

CrossRef

- Jesthi, D. K., & Nayak, R. K. Improvement of Mechanical Properties of Hybrid Composite through Interply Rearrangement of Glass and Carbon Woven Fabrics for Marine Applications. Composites Part B. 168, 467-475 (2019).

CrossRef

- Verma, D., & Goh, K. L. Natural fiber-reinforced polymer composites: application in marine environments. Biomass, Biopolymer-Based Materials, and Bioenergy. , 51-73 (2019).

CrossRef

- Maurin, R., Perrot, Y., Bourmaud, A., Davies, P., & Baley, C. Seawater ageing of low styrene emission resins for marine composites: Mechanical behaviour and nano-indentation studies. Composites. 40, 1024–1032 (2009).

CrossRef

- Mouritz, A., Gellert, E., Burchill, P., & Challis, K. Review of Advanced Composite Structures for Naval Ships and Submarines. Composite Structures. 53, 21-41 (2001).

CrossRef

- Shenoi, R. A., & Dotkins, A. R. Design of Ships and Marine Structures Made from FRP Composite Materials. Comprehensive Composite Materials. Southampton: Elsevier Science Ltd, 429-449 (2000).

CrossRef

- Chen, W., Meng, Q., Hao, H., Cui, J., & Shi, Y. Quasi-static and dynamic tensile properties of fiberglass/epoxy laminate sheet. Construction and Building Materials. 143, 247–258 (2017).

CrossRef

- Giorgini, L., Leonardi, C., Mazzocchetti, L., Zattini, G., Cavazzoni, M., Montanari, I., et al. Pyrolysis of Fiberglass/Polyester Composites: Recovery and Characterization of Obtained Products. FME Transactions. 44, 405-414 (2016).

CrossRef

- Das, D., Dubey, O.P., Sharma, M., Nayak, R.K., Samal, C., Mechanical properties and abrasion behaviour of glass fiber reinforced polymer composites – A case study, Materials Today: Proceedings. xxxx. xxx. xxx (2019).

CrossRef

- ASTM D6110. 2004. Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. ASTM Int.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal