Study on Properties of Multi Walled Carbon Nanotube Reinforced Aluminum Matrix Composite through Casting Technique

Shuib Pasha S A* , Nayeem Ahmed M,

, Nayeem Ahmed M, Tilak S R

Tilak S R  and Anil Kumar B N

and Anil Kumar B N

Department of Mechanical Engineering,Brindavan College of Engineering,Bangalore-560063, VTU, Karnataka, India.

Corresponding Author E-mail: shuaib8787@gmail.com

DOI : http://dx.doi.org/10.13005/msri/180111

Article Publishing History

Article Received on : 12-Dec-2020

Article Accepted on : 07-Apr-2021

Article Published : 14 Apr 2021

Plagiarism Check: Yes

Reviewed by: Dr. Syed Nasimul Alam

Second Review by: Dr. Bharath V

Final Approval by: Dr. Sami Mahmood

Article Metrics

ABSTRACT:

Composite materials are defined as material systems consisting of mixture of or combination of two or more micro constituents insoluble in each other and differing in form and or material composition. In this study Metal Matrix Composite (MMCs) has been produced using stir casting method for performing the mechanical properties. Most of the engineering industries want light and better mechanical properties of components; this can be achieved by MMCs of Aluminium because of its excellent performance. In this research work we fabricate the Aluminium by liquid route. Here Al 7075 is used as a base metal and Multi Walled Carbon Nanotubes (MWCNT) used as sub metal with various percentages. Experiments were conducted to analyze microstructure, hardness & tensile strength. By using optical microscope and Scanning Electron Microscope (SEM) we analyze the sample specimens are well dispersion in MWCNT with AA 7075. Hardness and tensile strength increases with increasing of wt. %. Hardness of material increases with increase in percentages of MWCNT, whereas tensile strength of the material increases with increase in percentages of MWCNT and Elongation reduces

KEYWORDS:

AA7075; Hardness; MWCNT; Microstructure; Stir Casting; Tensile strength

Copy the following to cite this article:

Pasha S. A. S, Ahmed M. N, Tilak S. R, Kumar B. N. A. Study on Properties of Multi Walled Carbon Nanotube Reinforced Aluminum Matrix Composite through Casting Technique. Mat. Sci. Res. India;18(1).

|

Copy the following to cite this URL:

Pasha S. A. S, Ahmed M. N, Tilak S. R, Kumar B. N. A. Study on Properties of Multi Walled Carbon Nanotube Reinforced Aluminum Matrix Composite through Casting Technique. Mat. Sci. Res. India;18(1). Available from: https://bit.ly/3wNNFDP

|

Introduction

MMC’s are used to improve the mechanical properties. Omkar Aranke et al.1 in this study stir casting method are used to produce composites of AL-7075 with MWCNTs. It is observed that microstructure study under SEM shows the uniform dispersion of MWCNTs. In this investigation hardness, tensile strength and impact strength of the material increases with various weight of MWCNT. Chaitanya Gandhi 2 in this investigation stir casting method is used to get Al-MWCNT composites, here the wear rate gets reduced with increase of sub metal but severe condition 0.75% MWCNT shows the negative results compared with 0.5% of reinforcement. Ravikumar M 3 in this experimental study the distribution of Al2O3 and SIC by using stir casting method, the tensile strength increased with increase the weight % of SIC, the hardness value also increased and the wear rate decreased with increase the SIC weight %. R. Pérez-Bustamante 4 in this study, Al- MWCNT composite produced using by mechanical milling method. The mechanical properties increased from the nano composites. Kesavulu A 5 in this study by using stir casting method; Al with fly ash composite, here with the addition of fly ash, the density of Al-fly ash is decreased. Again with the addition of fly ash the hardness and tensile strength of Al-fly ash is increased. Sedat Ozden 6 in this investigation we prepare Al reinforced with SIC by using stir casting method, here higher impact toughness was found in the varying weight % compare to pure aluminium. S. E Shin 7 in this investigation by using mechanical milling and the press-and-sinter process, Al2024 with MWCNT composite is produced. This study used get good tensile properties like better yield strength, young modulus and elongation to failure. These properties of materials are widely used in applications such as automobile parts. Sabitha Jannet 8 in this investigation by using stir casting method, AA-5083 with SiC & MWCNT composite is produced. Here Tensile strength of the composite increased as the wt. % of the MWCNTs increased. Mehrdad Shayan 9 in this study stir casting method is used to produce composites of AA2024−TiO2. Here the microstructure changes due tothe presence of nano particles agglomerations, and the increased porosity and the mechanical properties of the products were improved by adding TiO2 nano particles to the matrix alloy.B.N Yadav 10 in this investigation hybrid composites is produced, LM 13 Alloy with MWCNT &SiC through stir casting technique.Here The plateau stress and energy absorption increase with the individual addition of MWCNTs and SiC, but when both were added together the improvement is more than individual addition. Nekilesh 11 in this study AA5083 – MWCNT (1.5 wt %) was fabricated using compo-casting method to study the corrosion behavior. Here from the PDP and EIS experiments is evident that the AA5083 – MWCNT have better corrosion resistance than the AA5083 matrix material.M Sanju12 in this study by using stir casting method Al7075 with MWCNT and fly as hhybrid composite is produced. Here the percentage of reinforcement affects the hardness of the material and reduced the wear rate with the increase in the reinforcement.

Materials

Composition of Al7075 is shown in the table 1. Al-7075 is consists of good mechanical property like hardenability and finds its application in aircraft and automobiles.

Table 1: Chemical composition of Al-7075

|

component

|

Al

|

Zn

|

Mg

|

Cu

|

Cr

|

Fe

|

Si

|

Mn

|

Ti

|

|

Wt. %

|

87.1-91.4

|

5.1-6.1

|

2.1-2.9

|

1.2-2

|

.18-.28

|

Max. 0.5

|

Max. 0.4

|

Max. 0.3

|

Max. 0.2

|

MWCNT’s is considered as the reinforcement with 90% of purity because of high strength as well as low density. (Table 2). By using various weight % of MWCNT composites was prepared., and CNTs having a better lubricating properties.

Table 2: Properties of MWCNT

|

Property

|

Value

|

|

Purity ( % )

Avg. Dia. (nm)

|

>99

9.5

|

|

Avg.Length (µm)

|

1.5

|

|

Surface area

(m2/g )

Density (g/cm3)

|

400

1.312

|

Methodology

Preparation of MWCNT

MWCNT and acetone solution stirring it in a magnetic stirrer for 30 to 40 minutes (quantity sufficient to stir). Now we get a mixture of MWCNT and acetone in a glass beaker, keep this aside by covering the top with aluminium foil. Now take a glass beaker of tween 80 liquid, sodium lauryl sulphate and acetone. Tween 80is a non-ionic surfactant that is widely used as an emulsifier in cosmetics, pharmaceuticals and food products.

TWEEN 80 is a polyethylene sorbitol ester, with a calculated molecular weight of 1,310 daltons, assuming 20 ethylene oxide units, 1 sorbitol, and 1 oleic acid as the primary fatty acid.

First an emulsion of MWCNT was prepared, and then we will be having two glass beakers- Beaker 1 with solution MWCNT and acetone. Beaker 2 with solution of liquid tween 80, sodium lauryl sulphate and acetone then carry both the solutions carefully. Now Al7075 meltedin 850°C and then put simultaneously both the solutions from beaker 1 and 2 into the melt, stir and pour into the moulds. Acetone was used as a dispersion medium, sodium lauryl sulphate was used to disperse Nanotubes and Tween 80 was used as an emulsifier.

Preparation of Composite

Significance of stir casting technique.

Furnace type: Electric Resistance furnace

Maximum Temperature: 10000C.

Power capacity: 6KV.

VOLTAGE: 440V.

Stirrer: Mechanical stirrer.

By using stir casting bottom pouring method AMMC was prepared figure 1a. First AL 7075 ingots were taken in the furnace and heated at 8500C, some amount of Mg is added to the furnace to increase the wettability. After complete melting of Al 7075 a degassing tables or cleaning flux (COVERAL912) are added in the furnace to remove the unwanted flux and oxides impurities generated. To remove wet content in the sub MWCNT powder preheated to 3000C for 10-15 min, and added to the molten metal. By using mechanical stirrer the mixture was stir uniformly for 10-15 minute at 300 rpm. After complete dispersion the entire composite setup poured in to the metallic die and allowed for solidification. The specimens are prepared for varying percentages of reinforcement shown in the figure 1 c.

Figure 1: (a) Electric Resistance furnace;(b)Metallic mould; (c) Casting

Specimen preparation and Tests

Micro structure

By using Optical Microscope micro structure characterization was studied, specimens are prepared according to the ASTM standards (ASTM E407). By using polishing machine the specimens are polished with different grades.

Micro hardness:According to the ASTM norms (ASTM E10-18)

the specimens are prepared. The specimens are tested under Vickers’s hardness tester with varying load (gf) and dwell time (sec). Four readings of each sample were taken ata distance of 1 mm and the mean value is taken as a result.

Tensile Strength:As per ASTM norms (ASTM D638) specimens were prepared

By using UTM the specimens were determined.

Results

Micro structure

From the figure 2 clearly shows the both unrein forced and reinforced sample are micro tested with different % of MWCNT. Fig. 2. (B) to (D) shows the clearly distribution of MWCNT into Al7075. The presence of MWCNT along the grain boundaries restricts the growth of grain size during solidification and also from Fig. 2. (c) to (d) some porosities shown in the microstructure because agglomeration of CNTs in some areas in the base matrix. This is due to the act that the excess amount of CNTs does not get any room to fill the voids and hence start to agglomerate at one place.

Figure 2: (a) Al7075 – 0 wt % (Magnification X100); (b) Al7075 – 0.25wt % (Magnification X100); (c) Al7075 – 0.5 wt. %(Magnification X100); (d) Al7075 – 0.75 wt. % (Magnification X100)

Micro hardness

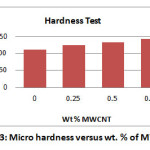

The study of hardness test with different sample was shown in graph. From the result cleared that hardness increases with increase in the wt. % of reinforcement because MWCNT has high tensile strength and stiffness properties.

Figure 3: Micro hardness versus wt. % of MWCNT

Tensile Strength

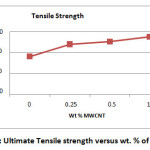

It is the ability of the material to withstand in tension or elongation, tensile strength of specimens was increased with increase in reinforcement weight fraction because MWCNT has high tensile strength and stiffness properties. Due to the presence of MWCNT the growth of grains has been restricted at grain boundaries.

Figure 4: Ultimate Tensile strength versus wt. % of MWCNT

Conclusion

Following conclusion were derived from the varying % of MWCNT with different samples.

Microstructure shows the uniform distribution of MWCNT throughout the matrix alloy, and there is a presence of tiny holes (0.5% MWCNT) and cracks due to agglomeration of CNTs in some areas in the base matrix.Which has to be study in the future?

Hardness of the material was increased as weight fraction of MWCNT increased in the matrix alloy, maximumhardness of 148.35 HV achieved for 0.75wt% sample(Fig. 3).

When weight % increases, the tensile strength also increases (Fig. 4).

Acknowledgement

Authors would like to thank our Research guide for their continuous support and encouragement.

Funding Sourse

No funding sourse was received to carry out the research work presented in this research paper.

Conflict of interest

The author declares that they have no conflict of interest.

References

- OmkarBamane and SanketPatil (2018), Materials Today: (2018)8001–8007.

CrossRef

- OmkarAranke and Chaitanya Gandhi (2018), Materials Today: (2018)7748–7757.

CrossRef

- Ravikumar M and Reddappa H N (2017), International journal of engineering sciences & research technology, Value: 3.00, ISSN:2277-9655.

- R. Pérez-Bustamante, Materials Science and Engineering A 502 (2009)159–163.

CrossRef

- Kesavulu and F.AnandRaju, International Journal of Innovative Research in Science, Engineering and Technology, Vol. 3, Issue 11, November 2014, ISSN:2319-8753.

- SedatOzden, Applied science and manufacturing, 25 February2006.

- S.E.Shin,CompositesPartB106(2016)66-73

CrossRef

- SabithaJannet (2020), Materials Today: Proceedings 22 (2020) 1417–1423.

CrossRef

- MehrdadShayan (2020) Materials Today: Proceedings30(2020) 2891−2903.

CrossRef

- B.N. Yadav(2020), Materials Letters 279 (2020) 128271.

CrossRef

- Nekilesh (2020)Materials Today: Proceedings 22 (2020) 2725–2731.

CrossRef

- M Sanju(2020) Materials Today: Proceedings 22 (2020) 2460–2468.

CrossRef

Views: 562

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

, Nayeem Ahmed M,

, Nayeem Ahmed M, Tilak S R

Tilak S R  and Anil Kumar B N

and Anil Kumar B N

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal