Various Material Development Strategies for Suitable Catalysts of Photo Catalytic Water Splitting to Green Fuel H2:A Critical Review

Introduction

The high energy crisis, fossil fuels depletion & environment pollution becoming the major global challenges in recent and upcoming years 1. Due to global warming& pollution issues, today’s world is searching for a sustainable, clean, and environment friendly alternatives. With a vast study on fuel and its negative impacts, scientists came to know that, hydrogen fuel may be a solution for this crisis. H2 is a fantastic energy conveyer with a high CV and clean property. As a bountiful element, H2 appear in many substances in the earth likely seawater, Biogas, freshwater and fossil fuels, etc. For the production of H2 with zero or low impact on the environment, almost all Carbon-dioxide with other unwanted particulates should be separated when H2 is produced from fossils 2. Till now, hydrogen is mainly synthesized via steam reforming method where CO2 is formed simultaneously. And this CO2 is the key concern for today’s environmentalists, as it is the major greenhouse agent. Photo-catalytic water splitting may be a solution to these problems. Some other important sources of the hydrogen production process are Electrolysis, Thermochemical processes, Dark fermentation process, Thermolysis, Photo-fermentation or Bio-photolysis, Hybrid thermochemical cycles, and Photo-catalytic water splitting, etc. For ultra-pure H2 production, electrolysis is a more reliable, technically sound, and widely acceptable system. Electrolysis is a technique where direct current (DC) is used to drive the anion-spontaneous electrochemical reaction 3. To run this technique, immaculate power hubs may be engaged like as solar-powered energy, geothermal based energy, biogas energy, wind-powered energy, ocean and others. The energy produced from nuclear energy sources may also be used for driving this process. Hydrogen produces in this technique is purer than any other technique, O2 production was also high in this technique. But the major disadvantage of this technique is that a huge amount of electricity is needed to run the electrolysis technique and the initial set-up cost is expensive in amount. The major reaction involve with the electrolytic technique of water is generally written as:

On the other hand, thermochemical processes are another convincing process for hydrogen production. The thermochemical system is the process which mainly driven by heat as its primary energy. This type of process for the production of hydrogen is considered as the viable process for the probable alternative of the previous one. Most alluring support from thermochemical production cycles is no requirement of catalysts or agents to drive the process reactions 4. All chemicals, without water (main raw material), used here can be reused easily. Other mesmerizing support of these types of degradation process are: (a) H2 and O2 can be separate from mixture gas without membrane; (b) optimum energy requirement range of 327–927 oC; & (c) less electrical power consumption. This requirement of power can be provided by concentric solar energy, the geothermal energy, biogas, nuclear electricity, and other sources5. But the challenges of this technique is that the bulk amount of heat supply source is not available in everywhere and artificially generation of heat is also costly. Here alleviate temperature degradation of catalyst is a major challenge, which retard the hydrogen production rate.

On the other hand, thermolysis is another significant way of electrolysis where H2O is split to H2 and O2 at elevated temperatures ranging between 973K to1273K. Basically this process is more effective than generally used room-temperature splitting process where efficiency increases with the increment of heat. The electrical energy needed here is much less than the conventional methods. Zero GHG emission is possible here by using the clean source of energy like solar, geological, wind or nuclear (6).Heat recovered from another process (such as industrial boiler or heat exchanger) can also be effectively used to run this process (7).In high temperatures operating system, the process units must have met some definite requirements for effective H2 production. Most recent objections of these types of the process can be enlisted as: (a) stable electrolytic reagent synthesis with low electronic and strong ionic conductivity; (b) porous, low cost and chemically static electrode development for high electronic conductivity and finally (c) mechanically stable engineering materials at high temperatures. Again, Hybrid thermo-chemical cycles which conduct at low temperature is more viable while comparing with the thermally driven water-splitting system. Electrical and thermal energies fulfill the outer energy demand of particular reactions as hybrid systems conducted at lower temperatures. A major advantage of these types of systems is that H2 generation from low-grade energy sources. But the major findings of this technique are that bulk amount heat source is not available everywhere and artificial generation of heat is also costly.

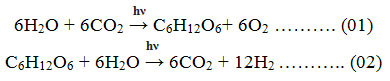

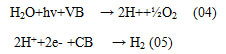

Bio-photolysis as well as photo-fermentation techniques are familiar as photon-based biochemical H2 generation from water. The main privilege of this technique is the capability to generate H2 from H2O in aqueous media at conditioned temperature & pressure 8. Here in the Bio photolysis processes light-sensitive micro-organisms are used as biological converters in a special bioreactor. Here Microalgae are most preferable among all microbes because they are culturable in suitable media 9. Cultured microalgae isolates have the capacity to produce H2 in a closed system and they show high H2 yields. The primary hydrogen generation reactions using photo-activated enzymes are the following:

However, this process is demonstrated at laboratory scale only and piloting is not yet possible to support the industries at the commercial level. Again Dark fermentation is a fermentation process which defined as the transformation of biochemical energy of organic to different forms of energy in dark conditions (during the reduced supply of light). In this process biochemical energy available in organic matter used to obtain H2 in absence of light 10. Bioreactors used in these types of fermentation are cheaper and simpler in comparison with photo-fermentation because this method does not need solar input processing. There are several other benefits of H2 production by dark fermentation like, 1 H2 production from organic waste and (2) stabilized & control in bio-waste for reducing potential danger of pollution 11. The dark fermentation process can be implemented in water treatment units for H2 production from organic wastewater. H2 production costs can be reduced by using inexpensive and readily available organic wastes (including wastewater). But the major disadvantage of this method is that the hydrogen production rate is very low and huge amount of reagents are required for continuous fermentation process which are non-recyclable.

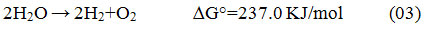

From all available H2 production the process discussed here photo-catalytic water splitting using sunlight has been widely believed as a promising process for green and environment-friendly hydrogen generation, where a chemical reaction occur while following with the alteration of Gibbs free energy (Eq. – 3)12

This type of Water Splitting has harmony with photosynthesis because both of them are uphill type. From this site, the water-splitting system can be evaluated as artificial photosynthesis. The utilization of green, inexhaustible and sustainable solar energy is an urgent need to avoid the greenhouse effects. A huge amount of research articles are circulating every year on solar energy transformation systems like photo-catalytic conversion of organic pollutants, hydrogen (H2) gas production through photo-catalytic water splitting, photovoltaic cells, and dye-sensitized solar cells 13. Photo-electrochemical water splitting process by Fujishima & Honda in the year of 1972 is most variant of this technique 14. Following this way, till now H2 production by Photocatalytic water splitting is considered as a promising technology for green energy revolution 15-17. (TiO2)titanium oxide 18-20, (g-C3N4)Graphitic-Carbon Nitride 21-23 and (CdS) Cadmium Sulfide (24-26)are three widely studied catalysts for water splitting in the last few decades. Among them, titanium oxide (TiO2) is found to be more superior, and a benchmark photo-catalyst still now 27.

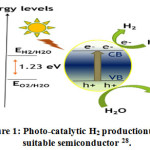

Figure 1: Photo-catalytic H2 productionusing suitable semiconductor 28.

Due to its photostability, efficiency, band edge, non-toxicity and sustainity it became a burning topic in this sector 29-34.The mechanism of Photocatalytic activity of TiO2 based catalyst for water splitting are illustrated in Fig. 1.0 35. The overall water splitting reaction on a photo-catalyst comprised of the following half reactions:

Overall Reaction:

:

:

Herein, an overview of current development in photocatalyst, a comparison of different water splitting processes, various catalyst development techniques especially doping on composite matrix, its effect on hydrogen production and various types of doping technique are critically explained. Different techniques for catalyst development including doping, Heterojunction, Dye sensitization, etc. are explained here. A complete study on doping is discussed here from all of its aspects. The numerous factors that affect the photo-catalytic water splitting such as band gaps, morphology, temperature, light intensity, pH, oxygen vacancies, and activity of sacrificial reagents are then scrutinously discussed here. Additionally, the reactor phenomenon and their commendation to further modification for H2 production are also explained here.

Advancement in photo-catalyst developments

As per characteristics of elements throughout periodic table, a good number of semiconductors have shown the capability for photo-catalytic water splitting to produce hydrogen. The requirements for a photocatalyst to be viable on large scale usage involves high quantum yield; being inexpensive, earthly abundance, recyclable, nontoxicity, resistant to corrosion, and photo-stable; and also must have a long lifetime 36. TiO2, since Fujishima and Hondas study at 1972, has been regarded amongst the most preferable photo-catalysts for splitting water for its conveniences, e.g. being abundant, inexpensive, noncorrosive, photo-stable, and environmentally friendly(14). Nevertheless, TiO2 can use only UV light for H2 evolution for its vast band-gap energy of 3.2 eV, separated electrons and holes in VB and CB of TiO2 can swiftly recombine and release energy or useless photons that barricade its practical utilization for Photocatalytic H2 generation using solar energy 37.Solar energy utilization basically depends on the electromagnetic wavelength of radiation in which photocatalyst shows activeness. Within 400 nm, the conversion efficiency of solar energy does not reach beyond 2% 38. Efficiency improves to 16% and 32% if the spectral wavelength reaches 600 and 800 nm respectively. Oxides other than TiO2, e.g. Cu2O, WO3, Fe2O3, and BiVO4, were also examined for photo-catalytic H2 production, but their photo-catalytic efficiency for hydrogen evolution is still restricted by small amount of light-harvesting, large electron-hole recombination rates, and poor transportation of charge 39. In times of BiVO4, its edge position is inconvenient for HER. For Cu2O, the efficiency solar to energy conversion is 18.0% theoretically, and it is vulnerable to auto-reduction in aqueous medium 40.That’s why it is very important to develop new photo-catalysts to use the visible range and near IR region wavelength. Metal-free and Earth-rich catalysts such as g-C3N4, graphene, oxide of graphene, carbon nano-tubes have been examined greatly owing to its possible cost minimization in the time of scaling up 41. In recent times g-C3N4 based materials free from metal have gained popularity for application in splitting of water 42. However, the catalyst g-C3N4 still suffering from many drawbacks, for instance insufficient surface morphology, reduced conductivity & large recombination rate 43. Another significant catalyst named metal-organic frameworks or MOFs are excellent photo catalyst for photo catalytic H2 generation 44. MOFs are composed of inorganic ions and organic substrate, which function as linking point & as connectors, correspondingly 45. At last Researcher heed their concentration on catalyst development by implementing different technique such as Doping, Nanostructure, Heterojunction, Dye sensitization, Formation of Solid Solutions, Sensitization with noble metal and Increasing Photo catalytically Active area etc.46. Amid all of the technique applied Doping and Heterojunction is more striking.. Table 01 gives the recent update on catalysts with various morphology & photocatalytic H2 production efficiency47.

Table 01: Recent updates in photo-catalysts with different morphology and photocatalytic efficiency.

| Catalyst |

Morphology

|

Synthesis method

|

Source of irradiation

|

H2 generation rate

|

Ref.

|

| Ag/TiO2, Hg |

nanoparticle

|

sol-gel

|

Vapor lamp (365 Nm)

|

910 mmol g1 h1

|

(48)

|

| Ni/TiO2, Pyrex |

nanosheets

|

solid state reaction |

F lamp, 100 W (365 Nm) |

26,000 mmol g1 h1

|

(49)

|

| Fe3+ ions doped and Ag deposited TiO2 |

nanoparticle

|

solvothermal |

UV light Source |

515.45 µmol/h/g

|

(50)

|

| Fe/ TiO2 |

Na

|

anodization |

xe arc lamp

|

174.30 mmol g1 h1

|

(51)

|

| Cu/ TiO2 |

nanotubes

|

anodization |

300 W, xenon,lamp |

28,700 mmol g1 h1

|

(50)

|

| Au/ TiO2 |

Na

|

anodization |

300 W, xe lamp

|

3550 mmol g1 h1

|

(52)

|

| Cu/ TiO2 |

nanoparticle

|

commercial tio2

|

125 W, Mercury Vapour lamp ( High Pressure)

|

01–07 µmol/min

|

(53)

|

| Pt or Au/TiO2 |

nanotubes

|

anodization |

Xe/Hg lamp ( High Pressure)

|

.06 µmol/cm2/h

|

(54)

|

| Au/Ti0.9O2

|

nanosheets

|

solid state reaction |

xe lamp 300 W

|

6753.00 µmol/h/g

|

(55)

|

| TiO2/WO3/Au |

Na |

electrospinning

|

Xe Arc lamp,300 W

|

270 µmol/h

|

(52)

|

| rutile TiO2

|

nanosheet

|

solvothermal

|

300 W, xenon lamp

|

22 mmol/g/h (5 h)

|

(56)

|

| N/TiO2, PdO & Pt loaded NTiO2

|

nanoparticle

|

sol-gel

|

400 W, mercury lamp

|

55.0,544.0,772.0 µmol/h/g |

(48)

|

| SMK-TiO2 |

nanoparticle

|

sol-gel

|

150 W Mercury lamp ( Medium Pressure)

|

3.3 mmol/240 min

|

(57)

|

| Co-moderated TiO2

|

nanoparticle

|

commercial TiO2

|

300 W, Xenon lamp

|

Nanoparticle

|

(58)

|

| Ag-Fe/TiO2 |

nanotubes Ti sheet(> 99% purity) |

electrochemical

|

Xenon Lamp& Hg Llamp

|

Nanotubes Ti Sheet(> 99% Purity) |

(53)

|

| Cu(OH)2/TiO2

|

nanotube arrays

|

electrochemical anodization

|

300W, Xe lamp

|

Nanotube Arrays

|

(59)

|

Material (Catalyst) Development techniques

Most decisive characteristic of a photocatalyst are: its optimum band gap, surface morphology, crystal structure and stability under light irradiation..TiO2 based photocatalyst orAnatase TiO2 is the photocatalyst mostly subjected to modification techniques to enhance H2 production. Other oxides, e.g. g-C3N4, Cu2O, WO3, Fe2O3, and BiVO4, were also studied for photo-catalytic H2 production, rather their performance or efficiency for photocatalytic H2 evolution is evaluated by some factors like, light harvesting time and rate, charge recombination, band edge and low charge transportation 60. Also, catalysts such as g-C3N4, oxides of graphene, graphene, nanotubes, and CDQs have been extensively investigated to develop their properties as they can exhibit better efficiency 61 . Scientists are trying to develop the catalytic activity of photo-catalysts through several techniques. Some of these are

Catalyst Development techniques

Doping

Heterojunction

Dye sensitization

Sensitization with noble metal loading

Increasing Photo catalytically Active Area

Modification of surface

Nanostructure

modification with Co-catalysts,

Doping

Among all of the stable and effective techniques for the development of catalysts, doping is the most effective and widely applied way to gear up catalyst’s electronic activity as well as to accelerate the reaction surface. Non-metals and metals deposition onto the semiconductor surface enables supplying maximum active sites excellently for photo-catalytic hydrogen production. Besides, proper control of homogeneous distribution and metals particle size can supply sufficient active site resulting in maximum light transmittance 45. Catalyst modification induces more charges due to the reduction of band gap, hence exciting more electrons for the production of hydrogen 61. TiO2 is one of the prominent and pioneer catalyst with maximum efficiency from 1972 to now. Here, metal and non-metal doping of TiO2, elemental doping on titanium-based catalyst, doping on the various composite catalyst, such as g-C3N4, BiVO4, MoS2/Bi2S3, BiFeO3 are discussed in a brief.

Elemental doping

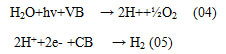

Doping deals with the replacement of an anion or cation within the surface of a substrate with some other agents(element) (Fig. 2a). Only an element of a similar charge and radius can be placed into a cation. The doping technique affects the band structure and decreases the band-gap by introducing a new forbidden level in the band. To choose the metal, its radius must match with the radius of the ion to be replaced. For example, in SrTiO3 base lattice, Ti4+ (0.0605 nm) will be replaced by Ta5+ (0.064 nm) and Cr3+ (0.0615 nm) ions where F (0.133 nm) atom will replace by O2 (0.140 nm) 62.

Figure 2: A 3-Dimensional representation for elemental doping on SrTiO362

Doping with single element

Single-element doping is the replacement of single sites with one similar type of foreign element (fig. 2a). Although the sites are normally cation sites in the perovskite structure, such as A & B, but most replacement occurs at B site (fig. 2b). Different effects on PEC materials will occur for each doping entity because of the difference in the arrangements of valence shell electrons. Primarily, new donors or acceptors cause to form by doping in the forbidden band, resulting in the reduction in band gap. Currently, Cu doped CaTiO3 shows an excellent result in H2 production with a rate of 1447.8 mmol h-1 under irradiation of UV light 63. Here, table 02 exhibits the expected improved data obtained from photo catalyst while doping with a different single atoms with variable parameters. Results incur that the CaTiO3 doping with Cu shows highest H2 evolution rate of 1447.8 mmol h1 with UV light 64. According to Shen P Et. al. SrTiO3 catalyst, synthesized by polymerization method yield 47.00 mmol h1 H2 evolution rate under λ>420.0 nm & λ63. On the other hand according to the study of Sun X Et. al. Sr2TiO4 exhibit maximum hydrogen evolution i.e. 97.7 mmol h1 when doping with Cr under light irradiation of (λ>250 nm, visible) 65. They developed this catalyst with Solid-state reactions mechanism and found highest output. Zou J-P Et. al., Yu H Et. al. get a regular output from SrTiO3 catalyst while doping with Zn and Cr respectively under UV light irradiation 66, 67. They synthesized the catalyst matrix in Sol-gel method. However, a significant result was found by Zhang HEt. al. from the catalyst Ti0.98Cu0.02O3 by Ca doping system under UV light irradiation. Zhang HEt. al. found that 1447.8 mmol h1 hydrogen evolution from catalyst while doping with Ca with Sol-gel method 64.

Table 02: Outcome of doping with single element at perovskites (titanate-based) structure.

|

Results obtained by single-element doping to titanate-based perovskites

|

| No |

Catalyst |

Dopants |

Method |

Light source |

H2 generation rate |

Ref. |

| 1 |

SrTiO3 |

Rh |

polymerizable complex, |

UV lamp |

47.00 mmol h1 |

(63)

|

| 2 |

Ti0.98Cu0.02O3 |

Ca |

sol-gel |

UV lamp |

1447.80 mmol h1 |

(65)

|

| 3 |

Sr2TiO4 |

Cr |

solid-state reactions |

visible |

97.70 mmol h1 |

(66) |

| 4 |

Ba5/6/6TiO3 |

Zn |

sol-gel |

UV lamp |

2.90 mmol h1 |

(66)

|

| 5 |

Sr2/3TiO3 |

Zn1/3 |

sol-gel |

UV lamp |

12.10 mmol h1 |

(64)

|

| 6 |

SrTiO3 |

Cr |

hydrothermal |

visible and UV lamp |

9.30 mmol g1 h1 |

(67)

|

Doping with double element

Here, replacement in the host material cause to happen with two types of foreign substrate at the same sites (B) or separate sites like X sites and A, B. Below in table 03, few effective cases listed through doping with the double element, along with the used parameters in experiments are shown. For example, on doping of cation with two elements, Sun et al. reported the increased hydrogen evolution rate to 211.4 mmol g1 h1 only with visible light (l > 415 nm) in SrTiO3, Ta5+ and Cr3+ at Ti4+ sites compared to 97.7 mmol h1 H2 evolution rate for doping of SrTiO3 with Cr. High improvement, above two-fold, in case of Ta addition 65. Furthermore, the reported rate of H2 evolution can be more accelerated if UV light source is included. On Co-doping, diffuse reflectance spectra revealed that Cr/Ta ions form a 3d donor level of Cr3+, above O 2p valence band. Yu et al. reported similar results, as in table 3, Yu Het. al. shows. A study shows that the rate of hydrogen evolution in a double element doped SrTiO3 was more about twice than that of mono element doped SrTiO3, while fabricated through the same method. For B 2p electron, top valence band position was around 0.38 eV 67. But as Kang & Parkreported the performance of composite catalyst material doped with double-element (15.4 mmol h1) was less than that of (Cr, Ta):SrTiO3. 68. Results reveals that application of double doping in cation sites shows best outcomes than doping with only single element.

Table 03: Outcome of doping with double element at perovskites (titanate-based) structure

|

Outcomes of titanate-based perovskites listed through doping with double element

|

|

No.

|

Catalyst |

Dopant |

Method |

Light source |

Rate of H2 generation |

Ref. |

|

1

|

SrTiO3 |

Ta, Cr |

spray pyrolysis |

λ>415 nm |

211.4 mmol g1 h1 |

(68) |

|

2

|

Sr0.9Bi0.1Ti0.9 |

Fe0.1O3 |

solid state |

λ > 250 nm |

185mmol g1 h1 |

(69) |

|

3

|

SrTiO3 |

B, Cr |

hydrothermal |

visible & UV |

15.41 mmol g1 h1 |

(67) |

|

4

|

CaTiO3 |

La, Ag |

sol-gel with ultra-sonication |

visible & UV |

1064mmol g1 h1 |

(70) |

|

5

|

SrTiO3 |

Al, Au |

solid state |

visible & UV |

348 mmol g1 h1 |

(71) |

Doping with triple element

In doping with triple element, three dopant elements replace original host structure atoms, where two replace at A and B sites and the left other replaces O sites. Researchers doped anion to substitute O2 with F for performing a research on material doped with double element in the same material as that used byKang HW et. al. in his work. Resultantly, for maintaining balance in charge, rest elements changed their charge in the initial structure. For instance, in case of SrTiO3:Cr/Ta , when F ions substitute O2 ions Rh4+ & Ti4+ reduces Rh4+ respectively to Rh3+& Ti3+and it partially induces Rh3+ and Ti3+ formation, respectively from Rh4+& Ti4+ in the sites B of the substrate, decreasing barrier towards the energy of activation and reducing stability 68. Here, charge distribution variation influences the band organization through making interactivity within electrons in a substrate. Also, F replacement in O2 sites results in cation deficiency and cation deficiency are the root cause for the doping element to improve H2 evolution in PEC. In a research by Kang HW et. al. they noticed that catalyst SrTiO3 yield 123.7 mmol g1 h1 H2 while doping with tri–element such as (Rh/Ta/F). They synthesized the catalyst with Spray pyrolysis method and the light irradiation was 4% under visible range. At the same time in a separate investigation, by Kang HW et. al. registered that 3887.9 mmol g1 h1 hydrogen was evaluated from theSrTiO3 catalyst while doping with Cr/Ta/F simultaneously.They also fabricate the catalyst matrix by spray pyrolysis method and conducted the reaction under visible light irradiation 71.

Table 04: Outcome of doping with tri-element at perovskites (titanate-based) structure

|

Outcome of perovskites (titanate-based) listed through doping with tri-element

|

| No |

Catalyst |

Dopants |

Fabrication Method |

Wave Nature |

Rate of H2 Production |

Ref. |

| 1 |

SrTiO3 |

F/Ta/Rh |

spray pyrolysis |

visible range |

123.70 mmol g1 h1 |

(71) |

| 2 |

SrTiO3 |

Ta/F Cr |

spray pyrolysis |

visible range |

3887.5 mmol g1 h1 |

(62) |

Doping on photo-catalysts based on Graphitic carbon nitride (g-C3N4)

Doping with metal

Recently Graphitic carbon nitride(g-C3N4), drawn a considerable concern as well as effectively investigated just as green, viable photo catalyst which results in a convenience e.g. metal-free, non-toxic semiconductor along with sensibility at the visible light range and narrow band gap , approximately, 2.7 eV 72. In addition, consistingwith simple earth abundant element C & N, it is of low cost and also shows unique resistivity towards photo corrosion for the strength of covalent bonds shown by the atoms of carbon and nitride 73. Also g-C3N4 shows exceptional photoluminescence (PL) characteristics, making it unstable as quality co-catalyst for other semiconductor catalysts 74. But in practice, implementation of g-C3N4 as photo catalyst is limited, due to smaller specific surface area and high rate of recombination of photo induced charges 75. Ultimately, Doping is one of the effectual initiative for adjusting electronic formations of g-C3N4 and to stimulate the reaction surface to escalate photo-catalytic activity owing to the work function and Surface Plasmon Resonance effect according to the previous writings 76.

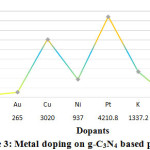

Figure 3: Metal doping on g-C3N4 based photo

In the year 2014,Zhong Y et. al. conduct Pt doping on photo-catalysts based on Graphitic carbon nitride (g-C3N4), under light irradiation of (300 W Xe lamp, l >420 nm) in Quartz reactor. They get hydrogen flow rate of 41.7 μmolh−1g−1 which was not significant to continue further work. Further in 2015 prominent researcher Huang Z et. al and Ma L et. al. again dopedg-C3N4 photo catalyst with Pt . The final product was then led for photoreaction under light irradiation of 300 W Xe lamp, l >420 nm in Quartz reactor and Pyrex reactor respectively 77, 78. Ma L et. al. found89.28 μmolh−1g−1 hydrogen production rate while Huang Z et. al. found 261.8 μmolh−1g−1in Quartz reactor. In 2018, Wang Y et. al doped potassium (K) on Graphitic carbon nitride (g-C3N4) based photo-catalysts. They found that, in Pyrex reactor under light irradiation condition of 300 W Xe lamp, l ¼ 400 nm, K doped g-C3N4 produce maximum 1337.2 μmol hydrogen at one hour 79. In the same year, another study of Liu M et. al. shows maximum 4210.8 μmolh−1g−1 efficiency of Graphitic carbon nitride (g-C3N4) based ,while doping with platinum (Pt) 80. But in 2019, Chen D et. al. found 79.00 μmol hydrogen by Mo doping on Graphitic carbon nitride (g-C3N4) based photo-catalyst 81.

Table 05: Metal doped photo-catalysts based on g-C3N4 for H2 production.

| Year |

Photocatalyst |

Dopant

(metal) |

Reactor |

Light Source |

Efficiency

μmolh−1g−1 |

Ref. |

| 2019 |

g-C3N4 |

Mo |

Pyrex reactor(P) |

Xe lamp, 300 W |

790.0 |

(81)

|

| 2018 |

g-C3N4 |

Au |

Pyrex reactor(P) |

Xe lamp, 300 W |

265.00 |

(82)

|

| 2018 |

g-C3N4 |

Cu |

Pyrex reactor(P) |

Xe lamp, 300 W, l >430 nm |

3020.00 |

(83)

|

| 2018 |

g-C3N4 |

Ni |

Quartz reactor (Q) |

,Xe lamp, 300 W, l >430 nm |

529.10 |

(84)

|

| 2018 |

g-C3N4 |

Ni-P |

Pyrex reactor(P) |

Xe lamp, 350 W |

937.00 |

(85)

|

| 2018 |

g-C3N4 |

Pt |

Pyrex reactor (P) |

Xe lamp,350 W |

4210.80 |

(80)

|

| 2018 |

g-C3N4 |

K |

Pyrex reactor (P) |

Xe lamp, 300 W l ¼ 420 nm |

1337.20 |

(79)

|

| 2017 |

g-C3N4 |

Co |

Pyrex reactor(P) |

Xe lamp, 300 W, l > 420 nm |

280.00 |

(86)

|

| 2017

|

g-C3N4 |

Pt |

Pyrex reactor(P) |

Xe lamp, 300 W, l ¼ 400 nm |

740.00 |

(87)

|

| 2015 |

g-C3N4 |

Pt |

Quartz reactor(Q) |

Xe lamp, 300 W, l >420 nm |

262.00 |

(88)

|

| 2015 |

g-C3N4 |

Pt |

Pyrex reactor (P) |

Xe lamp, 300 W l >400 nm |

890.20 |

(78)

|

| 2014 |

g-C3N4 |

Pt |

Quartz reactor (Q) |

300 W,Xe lamp, l >420 nm |

420.00 |

(77)

|

Non-metal Doping

Besides metal doping, doping with non-metals can effectively increase semiconductor’s photo-activity. In the modification of g-C3N4 polymers, doping with O, S, B & N; (the non-metal elements) shows excellent result while comparing with others. Its optical & electronic nature were effectively optimized for promoting photo-catalytic activity as a result of improved optical absorption process along with increased charge mobility. Hydrogen gas evolution performance should be enhanced as loading of various type of non-metal element that tunes the catalyst formation by reducing the band gap, inhibiting electron-hole pair recombination rate and stabilizing the catalyst. Zhou et al., during 2016, reported near 3.3 time’s higher hydrogen production than undoped g-C3N4 over modified N-doped g-C3N4 photo-catalyst (CN-20) with maximum reported hydrogen production was 64 mmol h-1 (Fig. 6(a)) 89. CN-20 catalyst was also documented for stability, as there was no notable decrease in the hydrogen production rate on repeated experiment under similar experimental situation used for four cycles (24 h), as Fig.6(b) reveals.

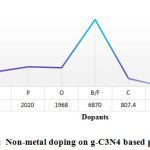

Figure 4: Non-metal doping on g-C3N4 based photocatalyst

In another study by Chen et al. reported the 12 times higher enhanced photo-catalytic performance for sulfur loading than pristine g-C3N4 and long term stability for the water-splitting process, as it is documented in Fig. 6(c). This one resolved that S loading is able to efficaciously enhance the specific surface area, persuade the formation of nitrogen vacancy, retard photo produced electron-hole pair recombination rate and improve the visible range responsiveness of the catalyst 90. Similarly specified the non-metal Br doped g-C3N4, was also appeared having long-term stableness on visible range photo-catalytic activity for 20 h with highest hydrogen generation rate of around 48 mmol h-1 as in the Fig. 6(d) showed. They also suggested that, the mechanism of reaction for water splitting using photo catalyst designed for CNBr as demonstrated in the Fig. 6(e). 91. Here, Table 7 demonstrates the cases for the non-metal doping on g-C3N4 aimed at water splitting using photo catalyst.

Table 06: The recent study of Non-metal loading on photocatalyst based on g-C3N4 for hydrogen generation.

| Year |

Photocatalyst |

Dopant

(inorganic) |

Reactor |

Light Source |

Efficiency

μmolh−1g−1 |

Ref. |

| 2019 |

g-C3N4 |

S

|

Pyrex reactor (P) |

Xe lamp,300 W,λ = 420 |

1511.2 |

(92) |

| 2019 |

g-C3N4 |

P

|

Pyrex reactor(P) |

350 W, Xe arc lamp, λ > 420 nm |

2020 |

(93) |

| 2018 |

g-C3N4 |

O

|

Pyrex reactor(P) |

300 W, Xelamp λ = 420 |

1968.00 |

(94) |

| 2018 |

g-C3N4 |

B/F

|

Pyrex

reactor(P) |

Xe lamp, 300 W, , λ> 420 nm |

6870.00 |

(95) |

| 2018 |

g-C3N4 |

S

|

Pyrex

reactor(P) |

Xe lamp, 300 W, λ> 420 nm |

240.1 |

(84) |

| 2018 |

g-C3N4 |

O

|

Pyrex reactor(P) |

Xe lamp, 350 W, |

1968.00 |

(94) |

| 2017 |

g-C3N4 |

P

|

Pyrex reactor(P) |

Xe lamp, 300 W, λ > 420 nm |

570.00 |

(94) |

| 2017 |

g-C3N4 |

C

|

Pyrex reactor(P) |

Xe lamp, 300 W, λ> 420 nm |

807.40 |

(96) |

| 2016,

|

g-C3N4 |

Br

|

Pyrex

reactor(P) |

Xe lamp, 300 W, λ ¼ 400 nm |

480.0 |

(91) |

| 2016 |

g-C3N4 |

N |

Quartz reactor(Q) |

Xe lamp, 300 W, λ > 420 nm |

640.0 |

(89) |

| 2015 |

g-C3N4 |

C |

Pyrex reactor(P) |

Xe arc lamp, 350 W, λ >420 nm |

540.0 |

(97) |

| 2014 |

g-C3N4 |

C |

Pyrex

reactor(P) |

Xe lamp ,Visible light, λ > 420 nm |

700.0 |

(98) |

Doping on BiVO4 based Photo-catalysts: BiVO4

Centenary of semiconductors are used for their Photo catalytic Properties, because it is impossible to fulfill all the conditions of photo catalytic water splitting by a particular element. Accordingly, element improvement stands the significant note for improving Photo catalytic water splitting act. In recent time, BiVO4 takes excessive consideration as photo-anode substances for PEC water splitting, since certain modified BiVO4 photo-anodes fulfill several essential necessities enlisted above 99-101. BiVO4 is a n-type semiconductor photo catalyst with the maximum band gap energy of 2.4eV. Here, BiVO4 engrosses sufficient amount of visible light spectrum and used as a stable, neutral, nontoxic, comparatively low-cost electrolyte 102-104. In comparison with other common O2 evolution photo catalyst likeFe2O3 and WO3, BiVO4 consumes a quite high CB (conduction band) energy (0.02 V vs. RHE). Therefore, the needless bias potential to elevate the photoelectrons upper the water reduction potential (0.0 V vs. RHE). However, the drawback is a very poor electrical conductivity with drippy water oxidation kinetics. Hence, several improvement techniques had undertaken for takeover the shortcomings of the BiVO4 catalyst as a photo-anode and to magnify its photo catalytic water splitting properties. Doping is one of the significant steps of them. Bismuth vanadate is suffering from the problems of the transfer of electron. Therefore, doping in BiVO4 can be a noble strategy to develop the electron transfer process in it and later photocurrent along with catalytic execution. In a research by Patil et al. informed that 2.00% of silver which is doping in uncontaminated BVO could rise its photocurrent density near about 3-fold as linked to an undoped BVO.In another work ,Fang and his team presented that, the pure BVO Catalyst have less photocurrent density rather than Ag-BiVO4 structure 105.

Where Martin Rohloff et al. described that the photo catalytic water splitting routine of the Mo-doped BiVO4 film photo-anodes are much better compared to their pure BiVO4. The photocurrent densities for Mo-BVO go to 1.90 mA cm−2 at 1.23V vs. RHE under solar light irradiation (100.00mW cm−2). In a work, Diane K. Zhong et al. described that the photo-current densities of BiVO4, after W doping were improved to 0.7 mA cm−2 at 1.23 V vs. RHE under 1.0 sun light illumination (100.00mW cm−2) 106. Amongst surface modification techniques deposition of catalysts layers on the BiVO4 surface, cobalt phosphate (Co-Pi) displayed the significant benefits of being effortlessly coconspirator with the BiVO4 surface. The Co-Pi alteration is a modest and effective technique to produce an earth abundant water-oxidation electro-catalyst for developing photo catalytic water oxidation 107. The modification of surface of BiVO4 semiconductor with W-doped and Mo-doped, are increased the photocurrent densities to 1.25 and 4.6 mA cm−2at 1.23 V vs. RHE under illumination of 1.0 sun light, respectively 103, 108. Heretable 07 shows the recent study of doping on BiVO4 composite photo catalyst.

Table 07: The recent study of doping on BiVO4 compositephoto-catalyst.

| Year |

Photocatalyst |

Dopant

(metal) |

Reactant Solution |

Light Source |

Efficiency

μmolh−1cm−2 h−1 |

Ref. |

| 2018 |

BiVO4 |

Nb-TiO2

|

1.0M KCl at PH 9.2 |

AM1.5Gillumination |

80μmolh−1cm−2h−1

|

(109) |

| 2018 |

BiVO4 |

Bi2S3 |

Na2S/Na2SO3 |

1000 W m−2 (1 Sun). |

417 μmolh−1cm−2 h−1 |

(106) |

| 2018 |

BiVO4 |

Nb-TiO2/W |

0.50 M phosphate buffer |

AM1.50G illumination |

80 μmolh−1cm−2 h−1 |

(110) |

| 2017 |

BiVO4 |

MDH |

0.50 M phosphate buffer |

AM1.50 G illumination |

21 μmolh−1cm−2 h−1 |

(111) |

| 2017 |

BiVO4 |

3-Fe2O3 |

phosphate buffer solution |

AM1.50 G illumination |

27.34 μmolh−1cm−2 h−1 |

(112) |

| 2016

|

BiVO4 |

CDs |

0.50 M phosphate buffer |

300.0 W Xe-lamp |

0.92 μmolh−1cm−2 h−1 |

(107) |

| 2016

|

BiVO4 |

HDP |

1.0M KCl at pH |

1.0 G sun illumination |

121 μmolh−1cm−2 h−1 |

(107) |

| 2016

|

BiVO4 |

WO3-NRs |

potassium phosphate(pH =7) |

solar light, AM 1.50 G |

102 μmolh−1cm−2 h−1 |

(105) |

| 2014

|

BiVO4 |

WO3/(W; Mo) |

0.5M K2SO4

(pH 7.0) |

100mWcm−2 , AM 1.50 G, |

75 μmolh−1cm−2 h−1 |

(105) |

| 2011 |

BiVO4 |

RhO2/Mo |

– |

AM1.50 G solar light |

9 μmolh−1cm−2 h−1 |

(113) |

| 2011 |

BiVO4 |

Mo

|

seawater |

simulated AM 1.50 G sunlight |

7 μmolh−1cm−2 h−1 |

(113) |

Doping on BiFeO3 based photo-catalysts: by Gd3+

In a work,Yuxuan Yanget. al. reported that, sol-gel synthesis along with photo-catalytic H2 evolution of BiFeO3 and Gd3+ doped BiFeO3. The results of this work exhibits increased photo-catalytic H2 evolution due to Gd3+doping.The H2 production rates are about 21.90 and 67.60mmolcm-2h-1 for BiFeO3 and Gd3+ doped BiFeO3, respectively. So, it is absolutely larger photocatalytic activity, the rate, more than three times of Gd3+ doped BiFeO3 than that for pristine BiFeO3. So, Gd3+ doping effects performance of BiFeO3 114. Also, It is mentionable that for a particulate photo-catalyst the H2 production ability depends on its different properties e.g. microstructure, crystallinity, electronic and optical etc.115.

Table 08: Key findings in development of Photocatalytic activity of BiFeO3 by doping with Gd3+114.

| Sl. No. |

Catalyst |

Doped

Element |

Preparation Method |

Efficiency |

Ref. |

| 01 |

BiFeO3 |

nil |

sol-gel synthesis |

21.9 mmolcm-2 h-1 |

Yuxuan Yang, et. al., 2018 |

| 02 |

BiFeO3 |

Gd3+ |

sol-gel synthesis |

67.6 mmolcm-2 h-1 |

Yuxuan Yang, et. al., 2018 |

Doping on TiO2& TiO2 composite photo-catalyst

TiO2 & TiO2 composite photocatalyst is the best, efficient, and cost-effective catalyst for photo-catalytic water splitting. Since 1972 enormous scientists or researchers work on it. The TiO2 & TiO2 composite photocatalyst could be further stabilized by the deposition of various metal and non- metal elements on its surface to increase catalytic activity. According to Hang Liu et. al. the photocatalyst Pt/PCN-777 exhibits excellent H2 production rate of 586 mmolcm-2 h-1in the presence of the TEOA reagent as a sacrificial agent under 300.0 W xenon lamp 116.The most important is that, this composite is recyclable under the normal catalytic conditions.A prominent researcher Y. Goto et. al. processed a TiO2/CoOOH/RhCrOx/SrTiO3:Al photocatalyst into a 5.0 *5.0 cm sheets & the sustainability of the substance was tested by a panel-type photo reactor with water depth 1.5 mm by simulated light and ambient pressure 117. The water splitting rate of these sheets are 5.7 μmolh−1g−1 and H2 generation efficiency is 0.4% at the initial duration of irradiation. Where according to Hao Lyu et. al the AQY of the resulting RhCrOx/SrTiO3: Al at the time of overall water splintering was measured to be 54.0% at 360.00 nm, which consistent with the ancestral work 118.

Table 9: The recent study of Doping on TiO2 & TiO2 based composite photocatalyst

| Year |

Photocatalyst |

Dopant

(metal) |

Reactant Solution |

Light Source |

Efficiency

μmolh−1g−1 |

Ref. |

| 2019 |

SrTiO3 |

Al |

Pure water |

300.0 W, Xe Lamp |

05.70

|

(118)

|

| 2018 |

PCN-777 |

Pt |

TEOA |

300 W, |

586.00

|

(116)

|

| 2018 |

RP/TiO2 |

Red-P |

Methanol |

350.0W, mercury Lamp |

276.00

|

(119)

|

| 2006 |

Sr3Ti2O7 |

NiOx |

Pure water |

Hg lamp,400–450.0 W |

144.00

|

(120)

|

| 2002 |

CaTiO3 |

NiOx |

Pure water |

Xe lamp,400–450.0 W |

30.00

|

(121)

|

| 2002 |

Sr4Ti3O10 |

NiOx |

Pure water |

Xe lamp,400–450.0 W |

170.00

|

(122)

|

| 1998 |

B/Ti oxide |

Pt |

Pure water |

Hg lamp,400–450.0 W |

22.00

|

(123)

|

| 1997 |

K2La2Ti3O10 |

NiOx |

Pure water |

Hg lamp,400–450.0 W |

2186.00

|

(124)

|

| 1997 |

TiO2 |

Pt |

Pure water |

Xe lamp,400–450.0 W |

568.00

|

(125)

|

| 1995 |

TiO2 |

Pt |

Pure water |

Hg lamp,400–450.0 W |

106.00

|

(126)

|

| 1987 |

TiO2 |

NiOx |

Pure water |

Hg lamp,400–450.0 W |

62.00

|

(127)

|

| 1985 |

TiO2 |

Rh |

Pure water |

Xe Lamp, 400–450.0 W |

449.00

|

(128)

|

| 1980 |

SrTiO3 |

Rh |

Pure water |

Hg lamp, 400–450.0 W |

27.00

|

(129, 130) |

| 1980 |

SrTiO3 |

NiOx |

Pure water |

Hg lamp, 400–450.0 W |

40.00

|

(127, 131) |

Doping (Copper) on MoS2/Bi2S3 Photocatalyst

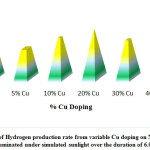

In a study, W. P. Cathie Lee fabricated a flower-like Copper-doped molybdenum disulfide/bismuth sulfide (Cu-MoS2/Bi2S3) photo-catalyst. The sample photo-catalysts with differing quantity of Cu were utilized in the photo-catalytic water splitting for H2 production under simulated sunlight irradiation. The photo-catalysts demonstrated high Photocatalytic activity with a most favorable Cu loading of 20.0mol%, reaching a total hydrogen evolution of 32.4 mmol/h on reaction for 6 hours(Fig:-5.0). The Copper doped samples showed increased performance rising about 1.4 times of non-doped samples. The reaction time taken by the different samples are also shown in (Fig: 5-2) respectively 132.

Figure 5: Variation of Hydrogen production rate from variable Cu doping on Na2S/Na2SO3 mixture illuminated under simulated sunlight over the duration of 6.0 h

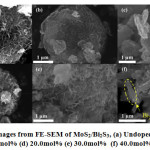

The crystal structure and surface morphology info of synthesized photo-catalyst were inspected by W. P. Cathie Lee using TEM and FE-SEM 132. The standard structure of non-doped MoS2/Bi2S3 is demonstrated in Fig. 2(a), where MoS2 have been seen to cover surface of Bi2S3, growing on it 132. In each of six images, crumpled MoS2 nano sheets is found to accumulate onto Bi2S3 surface, producing a flower-type frame 134. Upon copper (Cu) doping MoS2/Bi2S3, no notable alteration on samples surfaces were noticed (Fig. 2(b) & (c)). Still, at greater Copper loading to 20.0mol%, on the surface the grown MoS2 sheets were larger enough to be visible and distinguishable (Fig. 2(d)) 132. But on increasing Copper(Cu) to 40.0mol%, the distinct Bi2S3discoid’s not formed, rather some Bi2S3 noticed to be in rod form (indicated as yellow in Fig. 2(f)) where MoS2 sheets were in a arbitrary form 132.

Figure 6: Some images from FE-SEM of MoS2/Bi2S3, (a) Undoped (b) 5.0mol% (c) 10.0mol% (d) 20.0mol% (e) 30.0mol% (f) 40.0mol% 132.

Doping on miscellaneous composite photo-catalyst

Deposition of a foreign particle onto the semiconductor surface can supply maximum active surface for excellent Photo-catalytic H2production. There are many more option with semiconducting properties for Photocatalytic watersplitting. Among them K2La2Ti3O10, possesses a perovskite structure is one of a unique catalyst photocatalysis 135. H2 evolving happens on NiOx co-catalyst where O2 evolves from hydrated interlayer. Various niobate, titanate and tantalite photo-catalysts with perovskite structure been reported from the period of K2La2Ti3O10 photocatalyst was designed. Sr3Ti2O7 and Sr4Ti3O10 photo-catalysts have perovskite slabs of SrTiO3. La2Ti2O7, La2Ti2O7:Ba, KLaZr0.3Ti0.7O4 and La4CaTi5O17photocatalysts with perovskite structure which give a maximum quantum yield. Na2Ti6O13 and BaTi4O9 with a holo-tube type structure is also a unique photo-catalysts. On the other side Catalyst KTiNbO5 shows activity when it prepared through a polymerizable complex composite system. In a study by S. Ikeda et. al. they found thatK2La2Ti3O10 yield 2186μmol Hydrogen in 0.1M KOH solution.124. They used NiOx as dopant and the irradiated light intensity was 400 to 450 W mercury lamp with quartz cell. On the other hand in the year 2006 get 2390μmol Hydrogen from a quartz cell using K3Ta3B2O12 as a catalyst and Pure water Reactant Solution. Table 10 shows a brief summary of recent study on miscellaneous catalyst for Photocatalytic water splitting process. 136.

Table 10: Some study of doping on miscellaneous composite photo-catalyst.

| Year |

Photocatalyst |

Dopant

(metal) |

Reactant Solution |

Light Source |

Efficiency

μmolh−1g−1 |

Ref. |

|

2008

|

LiCa2Ta3O10 |

NiOx |

Pure water |

Hg–Q lamp |

59.00 |

(136) |

|

2007

|

CeO2:Sr |

RuO2 |

Pure water |

Hg–Q lamp |

110 |

(122) |

|

2006

|

Na2Ta2O6 |

NiO |

Pure water |

Hg–Q lamp |

391 |

(137) |

|

2006

|

K3Ta3B2O12 |

None |

Pure water |

Hg–Q lamp |

2390 |

(138) |

|

2005

|

Cs2Nb4O11 |

NiOx |

Pure water |

Hg lamp, 400–450 W |

1700 |

(139) |

|

2005

|

NaCa2Nb3O10 |

RuO2 |

Pure water |

Hg–Q lamp |

118 |

(140) |

|

2005

|

Sr5Ta4O15 |

NiO |

Pure water |

Hg–Q |

1194 |

(141) |

|

2005

|

Ba5Ta4O15 |

NiO |

Pure water |

Hg–Q |

2080 |

(120) |

|

2004

|

Y2Ti2O7 |

NiOx |

Pure water |

Hg lamp |

850 |

(142-144) |

|

2004

|

La3NbO7 |

NiOx |

Pure water |

Hg lamp, 400–450 W |

35 |

(142) |

|

2003

|

KaLaZr0.3Ti0.7O4 |

NiOx |

Pure water |

Hg lamp, 400–450 W |

230 |

(145) |

|

2000

|

K2PrTa5O15 |

NiO |

Pure water |

Hg–Q |

1550 |

(146) |

|

1997

|

Rb2La2Ti3O10 |

NiOx |

0.1 M RbOH |

Hg–Q |

869 |

(147) |

|

1997

|

K2La2Ti3O10 |

NiOx |

0.1M KOH |

Hg lamp, 400–450 W |

2186 |

(147) |

|

1996

|

KTaO3 |

Ni |

Pure water |

Hg–Q |

60 |

(148, 149) |

Heterojunction

The heterojunction is the interface that takes place between two layers or sectors of varying crystalline semiconductors. These semiconducting materials have a different band gaps as contrary to a homo junction. Many reviews have shown that various semiconductors can be coupled with BiVO4 for favorable result. The formation of successful hetero junction has been reported between BiVO4 and WO3 150-152 , SnO2 153, 154, Fe2O3 155, 156, CuWO4 157, and CdS 158, 159. Kim et al.showed that hetero type dual photo-anodes, HDP, of BiVO4& a-αFe2O3. 156. Reports also implies largely increased photocurrent on HDP of BiVO4/αFe2O3 becoming permanent. 7 mAcm−2 photocurrent at 1.23V vs. RHE has been reported below 1 solar radiation making subsequent hydrogen production for BiVO4/αFe2O3 nearly 80μmolcm−2h−1 by Savioet et al. On the other hand, the Fe2O3/BiVO4 photo-anode containing 3 spin coated films demonstrated 1.63mAcm−2 photocurrent density at 1.23V vs. RHE, reported by Xia et al. that is nearly 2.2 times higher in comparison to pure BiVO4 photo-anode, submerged in 0.1M KH2PO4 (pH 7) electrolytic solution beneath AM1.5G sun light 155. Rates of hydrogen production for Fe2O3/BiVO4 has been around 28μmolcm−2h−1, quite larger in comparison to BiVO4 photo-anode. A BiVO4/CuWO4 heterojunction electrodes made by Pilli et al. via spray accumulation method was reported two times photocurrent density to pristine BVO at 1.0V vs. Ag/AgCl in 1.0M Na2SO4 electrolytic solution at pH 7. 157. In contrary to pristine BVO, BiVO4/WO3 largely enhanced the IPCE, Incidence of Photon to Current Efficiency, from 9.3% to 31% as reported by Grimes et al. referred it to the phenomenon of enhanced electron migration towards WO3 from BiVO4 160. Also, as reported by Savio et al., BiVO4 and ZnO pairing generate a significant, 2 mA/cm2 at 1.23V vs. RHE, photocurrent density in observable radiation range. 161. Similarly, four times amplified photo current of BiVO4/TiO2, pairing of BiVO4 and TiO2, has been reported by Kimura et al., contrary to pristine BiVO4 on 100mWcm−2 brightness , and they ascribed it to the formational alterations of BiVO4 which improved electron transferring throughout the junction 162.

Dye-Sensitization

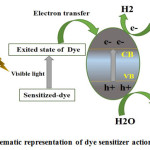

For HOMO and LUMO states being reconfigurable on anchorage of various ligands, dye sensitization is considered an effective way to improve the visible range response of photocatalyst for hydrogen generation. Broad usage for dye sensitization is to set visible light to transform energy. Some of the dyes are possible to be utilized in solar cells and Photo-catalytic methods, which have redox property and which are sensitive to visible light 163-165. On illumination of visible light, electrons from excited dyes can be infused to the conduction band of semiconductors, causing inauguration of photo catalytic actions as described in Fig:- 7. Some dyes such as safranine O/EDTA, T/EDTA, are susceptible to take in visible light to generate reducing agents electrons which have enough strength to generate H2 even without semiconductors 166. But it is very little H2 generation rate by dyes without semiconductors 164. Dhanalakshmi et al. carried out a parametric research to study the effect of applying 2þ as a dye sensitizer on Photocatalytic H2 generation from H2O, under visible light irradiation. 167.

Figure 7: Schematic representation of dye sensitizer action mechanism.

Dhanalakshmi et al. observed improved H2 generation rate under visible range radiation due to adsorption of dye molecules to the TiO2 on parametric research studying the influence of applying 2þ as a dye sensitizer on Photocatalyst based H2 generation from H2O. Splitting process 163 . Gurunathan et al. noticed influence of various dyes, for example, EDTA, during H2 generation for SnO2 photocatalyst using or not using sacrificial agents. Having band gap 3.5 eV and, SnO2 was unable to be activated on visible irradiation 168. On dye sensitization, SnO2 was capable of H2 generation on visible range irradiation. As observed, overall order of efficiency for dyes for improving rate of H2 generation is as following: Eosin blue>Rose Bengal>Ru(bpy) 32+>RhodamineB>Acriflavin>Fluorescein 167. By analyzing the phusico-chemical properties ot these dyes, a effective conclusion could be dawn [527]. Like as Rhodamine pose a longer absorption range maxima including more negative potential (.545V) than conduction range (.34V) of SnO2 167. But the problem is that it does not improve the H2 production rate significantly.

Table 11: Absorption wavelength maxima λmax(nm) dyes 169

| Sl. No. |

Dye |

Class |

λmax(nm) |

| 01 |

Thionine (TH+) |

Thiazin |

596 |

| 02 |

Toluidine blue |

Hiazin |

630 |

| 03 |

Methylene blue (MB) |

Thiazin |

665 |

| 04 |

Eosin |

Xanthen |

514 |

| 05 |

Azure B |

Thiazin |

647 |

| 06 |

Azure A |

Xanthen |

535 |

| 07 |

Azure C |

Thiazin |

620 |

| 08 |

Phenosafranin (PSF) |

Phenazin |

520 |

| 09 |

Saf-O/SO |

Phenazin |

521 |

| 10 |

Saf-T/ST |

Phenazin |

524 |

| 11 |

Neutral red (NR) |

Phenazin |

534 |

| 12 |

Neutral red (NR) |

Phenazin |

534 |

| 13 |

Fluorescein |

Xanthen |

490 |

| 14 |

Erythrosin B |

Xanthen |

525 |

| 15 |

Dye |

Xanthen |

530 |

Sensitization with Noble metal

Noble or precious metals, comprising Pt, Pd, Au, Ni, Rh, Cu & Ag, proved very efficient to improve photocatalytic activity of TiO2 170, 171. For these noble metals, Fermi levels are lesser in comparison to TiO2 and another similar photocatalyst. The photogenerated electrons transfers towards metal particles from conducting band of photocatalyst, depositing, while holes stay on the Valance Band of the photocatalyst. This decreases the possible rebinding of electron and hole greatly, leading to effective separation and stronger photo-catalytic reaction 172. The prominent researcher Anpo & Takeuchi accustomed ESR, signals to observe transferring of an electron from photo-catalyst towards Pt. Increased Ti3+ signals were observed on increasing irradiation duration and Pt loading decreased the of Ti3+ quantity. This investigation shows electron shifting towards Pt particles from TiO2 (Titanium dioxide). With electron deposition on particles, Fermi levels of the noble metals switch closer to the Conduction Band within TiO2 photo-catalyst leading energy levels towards more negative(-ve) direction which is effectual for splitting water, producing H2 173-175. Small size metal particle accumulation cause huge shifting of Fermi level on negative (-ve) direction on surface of TiO2 catalyst 173. Electrons deposited on the metal particles can move towards H+ upon the surface, adsorbed, and subsequently reduce H+ to form H2. Hence, noble metals having satisfactory work function able to assist in transferring electron, resulting in increased photo-catalytic activity 176. Bamwenda et al. compared H2 generation from water-ethanol solution using TiO2 photo-catalyst loaded with two different metals, Au and Pt. they also examined variant methods for depositing metal particle, for example, deposition–precipitation, photo deposition & impregnation method. 167.

They observed that Pt loaded TiO2 better operated than Au loaded TiO2. On the other hand, Au loading arranged by photo deposition operated better among other methods. Changing could be attributed to improved contact in the photo deposition system between TiO2 active sites and metal particles. But, the preparation system was hardly influencing in case of Pt-loaded TiO2 177. Among others Sakthivel et al. observed good loading in experiment for photo oxidation of acid green 16 treatment with TiO2 photocatalyst loaded with Pt, Au & Pd. As written above, photon absorption by TiO2 can be hampered by too much deposition of metal particles and also it may lead to formation of centers for charge recombination, resulting in less efficiency 177.

Increasing Photo catalytically Active Area

Photo catalytically active field in a photocatalyst is a necessary factor that readily impacts H2 generation rates. So, it was a concern to apply methods for enhancing photo catalytically active area. Two ordinary but efficient ways exist for enhancing the specific surface area. The first way is building uniform nanoparticle-containing thick surfaces and incorporating second material (nanowires, nano cells, nanoparticles, etc.) covering primary photocatalyst exterior is the second way. CdS nanorods as well as nanowire highly active photocatalyst for hydrogen generation can be produced through solvothermal & hydrothermal methods. Also, ultrasonic mediating precipitation, two-step aqueous route, and some additional ways can be effectively used to synthesis mesoporous (CdS) Nanoparticle 44.

Modification of Surface with graphene and other carbonaceous material

At present, Surface moderation of the photo-catalyst is performed with carbonaceous materials such as graphene, graphene quantum dot (GQD)s, carbon nano dots, carbon nanotubes (CNTs) and fullerenes (C60) for improving H2 generation in UV, UV-VM, and visible range area has drawn more remark because of the expanded visible-light absorption range and enhanced charge transfer 44. Graphene exhibits excellent electron mobility (200,000 cm2 V-1 s-1), substantial surface area specific (2630 m2 g-1), superior conductivity, electrical & thermal, and good chemical and physical stableness. Also, it is handily achievable from graphite bulk through mechanical, chemical, and thermal ways 178, 179. Zhang et. al. pointed out the synthesis of grapheme /TiO2Nano composites and the improved photo catalytic hydrogen production through splitting of water, as well as observed that the photo catalytic performance of grapheme /TiO2 Nano composites rely on rGO ratio and calcination process 180. In another work of Li et al., graphene quantum dot(GQD)/ TiO2 composite co-doped with sulfur and nitrogen (S.N-GQD/TiO2 photocatalyst) showed much improved performance than pristine TiO2 caused by improved visible radiation absorbance and efficient dissolution and transferring of photo generated charge 181. Fan et al. systematically conducted an inspection on reduction method influence on the hydrogen production performance of the Nano composite TiO2/RGO, and observed that Nano composite produced through hydrothermal method showed the best performance in H2 generation activity on UV-Vis light radiation 182 . Also, Fan el al. observed that grapheme quantum dot anchored TiO2 showed improved photo catalytic hydrogen generation performance on using methanol solution because of graphene quantum dots(GQD) operating as effective reservoirs for electron and fantastic photo sensitizer’s for Titanium dioxide 183.

Formation of Solid Solutions

A Solid solution production for compressing band-gap of semiconductors is a proper way to enhance efficiency for visible light absorption and utilization. Solid solution of ZnS and AgInS2, (AgIn) xZn2(1-x)S2 consisting of a compressed band-gap exhibited high visible-light photo-catalytic hydrogen production activities from aqueous S2- and SO32- solutions for sacrificial purpose.On AgInS2 ratio increment to ZnS, the light absorbance of (AgIn) xZn2(1-x)S2 solid solutions transferred to larger wavelengths because the photo-physical, photo-catalytic activities of (AgIn) xZn2(1-x)S2 solid solutions were dependent upon the structure changing for band position variation 44. In addition, easily produced solid solutions from same crystal formation ZnS and CdS, ZnS-CdS photocatalyst are fantastically responsive towards visible-light for hydrogen generation 184.

Reactor Design & Development

A chemical reactor is an enclosed system in which chemical changes are takes place. The scheme/model of a chemical reactor deals with multiplex aspects of chemical engineering. Chemical engineers design a reactor to maximize the efficiency for the given reaction. Reactor modeling is a significant part in photo-catalytic water splitting systems as well as hydrogen production plants.

Factors to be consider for reactor design:

Geometrical set-up of the reactor

Source of radiation (Natural or artificial)

Catalyst (Slurry or hold in support)

Sacrificial agents (CH3OH, Waste Water, etc.)

Light source position (35 – 450 angle, Concentric)

Sacrificial agents

Irradiation time

Shelf-life

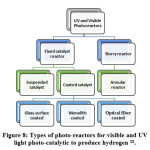

Photo-reactor Design

The photo-reactor is any chamber or vessel where reaction between the photo-catalyst and reactants takes place with the presence of photon (light) and Sacrificial reagents (where needed). Different types of reactor based on UV and visible light irradiation has been shown in Fig: 8 28. The photo-catalyst and light source are the main constituents of photo-reactor. For better photo-catalytic performance, an ideal photo-reactor must have uniform light distribution. 185. Tactics of operation and phase are important factors which determine the types of photo-reactor. Here Table-12 demonstrates the benefits and drawbacks of different photo-reactors. Table-12 summarized the benefits and drawbacks of different types of photo-reactor.

Figure 8: Types of photo-reactors for visible and UV light photo-catalytic to produce hydrogen 28.

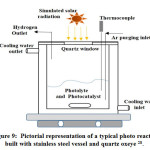

Batch-type photo reactor

The batch type reactor is the primary photo reactor in reactor types. Here Fig: 9.0 exhibits a batch type photo reactor for the catalytic hydrogen evolution from water. This types of the batch reactor are consist of a catalysts bed, reaction vessel, cooling water system, Quartz windows, light source, evacuation system, sample collection system, and gas detection device 28, 186. The water jacket around the reactor circulates water continuously to control the reactor and reaction temperature at a particular range. Light source will emit rays along the quartz windows.

Figure 9: Pictorial representation of a typical photo reactor built with stainless steel vessel and quartz oxeye 28.

Continuous annular photo-reactors

Continuous annular photo-reactors are composed of a ring shaped reactor with a light source located in the center. The inert N2 environment is maintained Into the reactor, to isolate the system from the surroundings. A constant flow of Ar gas bubble is provided through the reaction slurry to keep the suspension homogeneous. To analyze, a portion of the produced hydrogen gas is inserted to a gas valve of gas chromatography (GC). The benefit of continuous annular photo-reactors is to enhance the liquid-gas interfacial area, which simplifies the release of H2 from the photo-catalyst surface. One of the major drawbacks of these types of the reactor is, more photon can be received by the interior of the annular reactor than that of the exterior.

Photo catalytic membrane reactor

Photo catalytic membrane reactor (PMRs) is effective for sustainable production of hydrogen by suppressing the reversed reaction between O2 and H2. Pure hydrogen can be obtained in a single step without further purification. In the case of PMRs design, photo-catalyst and metal loading, the mechanical resistance, permeability, membrane morphology are important factors to be considered and needed to get excellent efficiency of catalytic membrane system while in hydrogen evolution. There are various types of PMRs for hydrogen evolution, such as H-type Photo-catalytic reactor (HPR), membrane electrode photo-catalyst assembly (MEPA), membrane twin reactor (MTR), and polymer membrane electrode assembly (PMEA) 28.

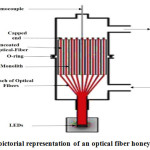

Optical Fiber and Honeycomb Reactors

Generally Optical fibers, made of silica, are used to transmit light from one end to another end of the fibers. Light is split into two parts by the variation of refractive index between the quartz core and the semiconductor, such as TiO2, coating during hitting the internal surface of the fiber 28. Some portion of the light is transmitted and reflected through the fiber, while the rest fraction excites and penetrates the titanium layer on the interface. Thus, photo-reactions occur through the formation of electron-hole pair. As a result, optical fibers are utilized to radiate the light properly in the interior of a photo-reactor 187. Light is passed through the fibers core by forming a cover which is lower refractive index that captures light beam in the core through total internal reflection 188. Formerly, H2 production rate was increased through photo catalytic water splitting using optical fiber coated with SiO2 and TiO2 189. There are several benefits of optical fibers such as: It has higher efficiency enlighten the interior of reactor uniformly and it causes higher interactions between irradiations and catalyst surface.

Figure 10: The pictorial representation of an optical fiber honeycomb reactor185

Monolith reactor

It is a multifunctional reactor which is integrated with separation and heat exchanger. The designs of a monolith reactor are uniform sets with a parallel line that can be constructed into various configurations (sizes and shapes). Application of monolith reactor having a narrow path with larger light beam interaction surface area (SA) can enhance the transformation and product rates 190. Because of its excellent properties the Ceramic monolithic reactor formations shows an attractive choice to commonly designed catalyst nubbles or powders. Monoliths has several advantages over typical catalyst powders or nubbles, such as: improved weight transfer rate, good coating adhesion, better porosity, minimal pressure fall, better thermal and mechanical strength 191. Current improvement in photo (light) technology exhibited that, when compared with other commercial reactors, the monolith reactors have several benefits over them. In 2017, splitting of water for hydrogen evaluation with sacrificial agent, ethanol, in a monolith photo-reactor has been tested by Gaudillere et al. 192. According to Tahir Met. al., the quantum efficiency (QE) in micro-channel monolith reactor gave much higher (0.10%) than deal with cell type reactor (0.0005%).193 In another analysis performed by Tahir Met. al. they used/applied photo catalyst NiOeIn2O3/TiO2 which showed superior performance in the batch type monolith photo reactor than considering cell type reactor under identical conditions of reaction with efficiency of 14.13 times higher 194.

Particulate photo catalytic reactor

Particulate photo catalyst reactor systems are narrated here having some facilities in case of designing cost and scale-up potential as compared with photo electrochemical and photovoltaic systems 195. However, the development of photo catalytic water splitting set up even to the one to one meter scale has rarely been published, although the ultimate demand of fabricating plants tens of square kilometers 186. Elsewhere, the power generation through photovoltaic system have been installed and commercialized in an extend phase. This indicates a non-stop challenge to the application of photo-catalytic splitting of water as a way of production of solar fuel.

Figure 11: The pictorial representation of a photo-reactor (large scale) for photo-catalytic reactions with an immobilized photo-catalyst.186

Formerly, photo-catalytic water splitting has been studied in flask-type reactors using suspensions of photo-catalyst powders on the small-scale Nevertheless, the disadvantage in the development of suspension systems can be guessed from the deficiency of big-scale displays of water splitting by sunlight overall with noticeable values of STH. Honestly, this an attempt is annoying on big scales for various factors 186. Firstly, it is challenging to lessen the costs of reactor, such as huge water is required. For example, 1 cm depth, water quantity in a reactor increases in values of 10 kg one square meter and reactors seem to be larger and high cost. This is not be feasible on a big scale production process assuming that the highest cost allowed for the complete hydrogen production systems is about US$102 m-2, as mentioned earlier 196. Secondly, there is a tendency of the particulate photo-catalysts to precipitate to the basement of the reactor if not the reactor is positioned perfectly. They do not receive incident light effectively too. Tubular shaped reactors combined with a CPC (compound parabolic concentrator) have been experimented for big scale industrial operation of photo-catalytic hydrogen evolution reactions (HER) in the availability of sacrificial reagents (SR) 197. In the research done by Jing et al., CPCs contain the highest half incident beam angle of 14°, length of 0.4 m, and whole arm of 1.5 m, and pyrex reactor tubes 1.6 m in length were used. However, as particulate photo-catalytic reactor is scalable and it has low operation and maintenance cost, it is more effective than others.

Table 12: The benefits and drawbacks of different types of photo-reactors:

|

Reactor

|

Findings |

Drawbacks |

Ref. |

|

Slurry reactor

|

- Can be operated in fixed bed mode or continuous flow patterns

- Combination of gas-liquid-solid phase

- Continuous stirring causes the additional cost

- Active contact surface for reaction is low

|

|

(28, 185)

|

|

Fluidized reactor

|

- High photo-catalytic activity

- Efficient rate of heat and matter transfer by

vigorous excitation of solid

- Abrasion of particles and attrition of the catalyst may

causes erosion in reactor

- difficult to separate from mixture

|

|

(188, 198)

|

|

Optical reactor

|

- Surface area is larger

- Efficiency of light utilization is higher

- Efficient processing capacities of the catalyst

- Deactivation catalyst at high temperature

- Maximum reactor volume cannot be applying

Uniform coating of fibers is complex

|

|

(188)

|

|

Monolith reactor

|

- Ratio of surface to volume is higher

- Pressure drop is low

- Flow rate is higher

- Light efficiency is low

- Catalyst adhesion on wall is lower

|

|

(188, 198, 199)

|

|

Fixed bed reactor

|

- large Surface area

- minimum reaction period

- lower Operating cost

- low Light efficiency

- lower adhesion

|

|

(188, 198, 199)

|

|

Particulate photo-catalyst reactor

|

- Minimal fabrication cost

- High scale up potential

- Operating cost is lower

- reactors tend to be bulky

- water is required in large volumes

|

|

(186)

|

Process Parameters for photo catalytic reaction

Light intensity or Irradiation of light

Temperature effect

PH effect

Reactor design

Oxygen vacancies

Presence of Sacrificial agents

Miscellaneous factors affect

Light intensity

The higher hydrogen production rate is linearly related to light irradiation. The effectiveness of photo catalytic splitting of water can be improved with the rise in light intensity generating power more than the threshold level of activation 200,201. Two regions are available related to the photo-catalytic reaction related to the UV photon flux. One region is for laboratory research fluxes which are 25 mW cm-2. Compare to the reaction of recombination the hole electron couple is consumed quicker in a chemical reaction. During the half-order region, the intensity remains higher, the recombination rate is a major factor and creates less change on the rate of the change the reaction process. The change of the value of the reaction rate is related to the wavelength which appears following the catalyst spectrum of the adsorption with a minimum reading level with respect to the band potential energy 202 . In the year 2013, Baniasadi et. alannounced that the rate of hydrogen generation from Zinc-Sulfide (ZnS), increased by 20% with rise in intensity range of light from 90 to 100 mW cm-2 203. In another research work report by Leon and Tambago, indicated that the hydrogen (H2) production increased using Cd0.4Zn0.6S while the intensity of light was increased 204.

Figure 12: The comparison ofphoto-catalysts for hydrogen (H2) generationunder irradiation of solar Light for TNS(titanium nano sheet), TNT(titanium nano tube) and TNR(titanium nano rod)205

Temperature effect

The photo-catalytic behavior of catalyst material is introduced by temperature, since electron and hole generation is not related to it directly. But, the temperature has a crucial role to improve desorption of hydrogen gas (H2) from the surface area of the considering catalyst to accelerate the effect of photo catalyst. It is thermodynamically established that, temperature ameliorates the reaction process in maximum cases. The rate of change of applied temperature differs according to the change of catalyst. The photo-catalytic activity could be increased by the adjustment of the factor. The hydrogen (H2) production becomes slower when the value of the temperature goes down. In this process desorption limits the reaction mechanism. The higher valance electron in the valance band will be transferred to higher energy levels during high-temperature conditions. The electron and hole generation will initiate oxidation & reduction reaction respectively with charge carrier recombination 202. In 30℃, 40℃, 50℃ the hydrogen gas generation was 59, 92 & 370 mol/g.s respectively 206. Hydrogen generation increased from 4.71 mmol g1 to 15.18 mmol g1 after introducing a temperature rise from 45℃ to 55℃207. In a photocatalytic study it was found that the optimum temperature of this process should be 60℃ to 80℃.208

Table 13: Temperature effect on H2 production rate.

| Sl. No. |

Temperatuire0C |

H2 production rate |

Catalyst |

| 01 |

30 0C |

59.00 mol/g.s |

Pt/TiO2 |

| 02 |

40 0C |

92.00 mol/g.s |

Pt/TiO2 |

| 03 |

50 0C |

370.00 mol/g.s |

Pt/TiO2 |

pH Effect

The hydrogen (H2) generation from water splitting depends on the concentration of the proton which indicates the pH of the regarding solution. In the water-splitting process, an electron is generated throughout the reaction process. A significant organic species is needed for the proton reforming. It is recommended to generate hydrogen in a strongly acidic solution rather than in a basic solution (pH>7). Similarly, the band gap potential shift also depends on pH value [20]. In a CuOx/TiO2 catalytic medium with basic medium (pH 10) hydrogen production is maximum. The atom copper Cu (I) shows unstable behavior in TiO2 based acidic medium. In the visible light TiO2 part of the catalyst, Si/CdS/TiO2/Pt is unstable in a strong base or acidic reaction 209. The optimum pH value of a photo-catalytic reaction for better hydrogen production rate in CuAlO2/TiO2 catalyst surface is 11 210. The catalyst Pt/r-TiO2 has the ability to produce hydrogen up to 56.6mmol in a pH condition at 5.5 during 4h of operation from pH value 12 to 2.0 211. The hydrogen generation is 1200mmol g-1 h-1 in NiO/TiO2 catalyst in a pH condition 6.6.So the hydrogen generation is directly depends on the according pH reading of the reaction where the best pH reading is about zero [0.00] charge value 212.In an acidic solution of methanol-water the photosensitized TiO2/RuO2-MV2+ catalyst can generate enough hydrogen (H2) 213. The reduction reaction of hydrogen from H+ to H2 can be increased when more protons are present on the surface of the regarding catalyst in an acidic solution (pH<7).The hydrogen generation is rapid in the acidic solution than in the basic solution 203. So in a photo-catalytic reaction the hydrogen production is better in the acidic solution.

Oxygen vacancy

Oxygen vacancy is a significant factor to enhance H2 production as well as the ionic longevity increase. Paucity of oxygen can be produced by applying metal oxides with the process of catalyst synthesis, decreasing value and mixture 214. When the titanium-oxide (TiO2) is used as the titanium ion and oxygen gap are created at the same time. More titanium ions are produced because of the increasing oxygen gap. As a result, there is a situation of titanium defects, amorphous surface area disorder, and finally relative oxygen gap. This oxygen gap indirectly related to electron stability because of the absence of oxygen ion. Whereas, the regular lattice of the oxygen atom was taken by electrons, and the local state was formed by oxygen vacancies and Ti3+. Then, the VB holes of TiO2 were generated and the electrons excited to the CB of TiO2. At CB, the H+ reduce to H2 through a reduction reaction 215. So hydrogen gas generation without the recombination of the electron-hole and the amelioration of the charge longevity is the main aim to be achieved.

Reagent for Sacrificial behavior