Influence of Injection Timing on the Performance, Emissions, Combustion Analysis and Sound Characteristics of Nerium Biodiesel Operated Single Cylinder Four Stroke Cycle Direct Injection Diesel Engine

S. Prabhakar, V. N. Banugopan, K. Annamalai, G. Devaradjane, S. Jayaraj and P. Sentilkumar

Department of Automobile Engg, MIT Campus, Anna University, Chennai, India.

DOI : http://dx.doi.org/10.13005/msri/070125

Article Publishing History

Article Received on : 15 Apr 2010

Article Accepted on : 24 May 2010

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

The automobile sector which is growing day to day consumes the fossil fuel more than its growth. So there is a demand for exploring new sources of fuels for existing engines. This led to the growth in bio diesels which is an alternate fuel. An alternative fuel must be technically feasible, economically competitive, environmentally acceptable, and readily available. In this project esterified Nerium oil is used as an alternate fuel. A single cylinder stationary kirloskar engine is used to compare the performance and emission characteristics between pure diesel and Nerium blends. In this project selection of suitable nerium blend and selection of optimized injection timing for the blend is done. The Nerium oil blends are in percentage of 20%, 40%, 60%, 80%, and 100% of Nerium oil to 80%, 60%, 40%, 20% & 0% of diesel. From this project it is concluded that among all nerium and diesel blends 20% of nerium and 80% of diesel blend at 30º BTDC gives better performance nearing the diesel. When comparing the emission characteristics HC, CO is reduced when compared to diesel, however NOx emission is slightly increased when compared to diesel. Hence Nerium blend can be used in existing diesel engines with minimum modification in the engine. It also describes the usage of non-edible oil to a greater extent.

KEYWORDS:

Nerium; Injection timings; Esterification

Copy the following to cite this article:

S. Prabhakar S, Banugopan V. N, Annamalai K, Devaradjane G, Jayaraj S, Sentilkumar P. Influence of Injection Timing on the Performance, Emissions, Combustion Analysis and Sound Characteristics of Nerium Biodiesel Operated Single Cylinder Four Stroke Cycle Direct Injection Diesel Engine. Mat.Sci.Res.India;7(1)

|

Copy the following to cite this URL:

S. Prabhakar S, Banugopan V. N, Annamalai K, Devaradjane G, Jayaraj S, Sentilkumar P. Influence of Injection Timing on the Performance, Emissions, Combustion Analysis and Sound Characteristics of Nerium Biodiesel Operated Single Cylinder Four Stroke Cycle Direct Injection Diesel Engine. Mat.Sci.Res.India;7(1). Available from: http://www.materialsciencejournal.org/?p=2280

|

Introduction

Vegetable oils are considered as good alternative to diesel fuel due to their properties which are much closer to that of diesel. Thus, they offer the advantage of being readily used in existing diesel engines without much modification. They have a reasonably high cetane number. Vegetable oils have a structure similar to that of diesel fuel, but differ in the type of linkage of the chains and have a higher molecular mass and viscosity. The heating value is approximately 90% of diesel fuel. A limitation on the utilization of vegetable oil is its cost. In the present market the price of vegetable oil is higher than that of diesel. However, it is anticipated that in future the cost of vegetable oil will get reduced as a result of developments in agricultural methods and oil extraction techniques.

In India, forests and plants based non-edible oils are considered as the main sources for bio diesel production. Non–edible oils can be obtained plant species such as Jatropha, Karanja, Rubber, Mahua and Neem. However, it is not possible for us to get Nerium oil that much easily as that of other oils. Hence, in the present work, Nerium oil based bio-diesel is being considered as an alternate fuel for Diesel engines.

Experimental

Apparatus and Methods Transesterification of Nerium Oil

To reduce the viscosity of the Nerium oil, trans-esterification method is adopted for the preparation of biodiesel. The procedure involved in this method is as follows: 1000 ml of nerium oil is taken in a three way flask. 12 grams of Potassium hydroxide (KOH) and 200 ml of methanol (CH3OH) are taken in a beaker. The Potassium hydroxide and the alcohol are thoroughly mixed until it is properly dissolved. The solution obtained is mixed with Nerium oil in three way flask and it is stirred properly. The methoxide solution with nerium oil is heated to 60°C and it is continuously stirred at constant rate for 1 hour by stirrer. The solution is poured down to the separating beaker and is allowed to settle for 4 hours. The glycerin settles at the bottom and the methyl ester floats at the top (coarse biodiesel). Methyl ester is separated from the glycerin. This coarse biodiesel is heated above 1000C and maintained for 10-15 minutes to remove the untreated methanol. Certain impurities like sodium hydroxide (KOH) etc are still dissolved in the obtained coarse biodiesel. These impurities are cleaned up by washing with 350 ml of water for 1000 ml of coarse biodiesel. This cleaned biodiesel is the methyl ester of Nerium oil. This bio-diesel of Nerium oil is being used for the performance and emission analysis in a diesel engine.

For the present work N20, N40, N60, N80 and N100 blends of Nerium oil bio diesel are being used.

|

Engine specification

|

|

|

Engine manufacturer

|

Kirloskar

|

|

Bore& stroke

|

87.5×110 (mm)

|

|

Number of cylinders

|

|

|

Compression ratio

|

17.5: 1

|

|

Speed

|

1800 rpm

|

|

Cubic capacity

|

0.661 litres

|

|

Method of cooling

|

water cooled

|

|

Fuel timing

|

27° (btdc)

|

|

Clearance volume

|

37.8 cc

|

The engine used for the investigation is kirloskar SV1, single cylinder, four stroke, constant speed, vertical, water cooled, high speed compression ignition diesel engine.

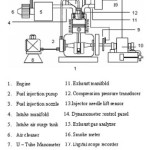

The kirloskar Engine is mounted on the ground. The test engine was directly coupled to an eddy current dynamometer with suitable switching and control facility for loading the engine. The liquid fuel flow rate was measured on the volumetric basis using a burette and a stopwatch. AVL smoke meter was used to measure the CO and HC emissions from the engine. The NOX emission from the test engine was measured by chemical luminescent detector type NOX analyser. For the measurement of cylinder pressure, a pressure transducer was fitted on engine cylinder head and a crank angle encoder was used for the measurement of crank angle. The sound from the engine was measured by Rion sound level meter. The experimental setup is shown in Fig.1

Figure 1

Test Method

The engine was operated initially on diesel for warm up and then with Nerium oil blends. The experiment aims at determining appropriate proportions of biodiesel and diesel for which higher efficiency was obtainable. Hence experiments were conducted for different proportions of biodiesel mixed with diesel. The blends were in the ratio 20%, 40%, 60%, 80%, and 100% with diesel. First these blends were tested at normal injection timing 27° BTDC at constant injection pressure 200 bar and with a constant compression ratio 17.5.Then for the best efficiency blend, the test were conducted at three different injection timings 24° BTDC, 30° BTDC and 33° BTDC and above procedure was followed. Shims were used to change the injection timings

Performance Analysis

Brake Thermal Efficiency

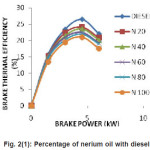

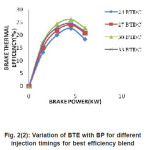

At normal injection timing of 27°BTDC the brake thermal efficiency for neat diesel at full load is 26.48 %,where as it was 24.08%, 23.56%, 22.45%, 21.923%, 21.07% for N20, N40, N60, N80 and N100 as shown in Fig. 2.1.The best thermal efficiency was obtained for N20 blend and was 2.4% less than that of diesel for full load. From the Fig.2.2 it was observed that brake thermal efficiency for different injection timings for best efficiency blend(N20) at 24°BTDC was 22.60%,30°BTDC was 26.12% and 33°BTDC was 24.61%.For N20 at 30°BTDC it was found to be 2.04% higher than N20 at 27°BTDC.. This may be due to better spray characteristics and effective utilization of air resulting in complete combustion of the fuel. For 24°BTDC the brake thermal efficiency is 1.48 less than normal the efficiency of injection timing. This is because of incomplete combustion due to retardation of injection timing.

Figure 2(1): Percentage of nerium oil with diesel

Figure 2(2): Variation of BTE with BP for different injection timings for best efficiency blend

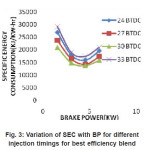

Specific Energy Consumption

Comparison of the specific energy consumption for the four different injection timings for best efficiency blend (N20) is shown in fig no.3. It can be seen that the SEC is the highest in the case of the 33°BTDC and is least in the case of 30°BTDC. This is because at 30°BTDC the fuel is optimally injected such that proper diffusion of the biodiesel takes place. At 33° BTDC more amount of fuel is injected into the combustion chamber because of the advance in the timing which leads to excess consumption of biodiesel. At 27° BTDC and 24° BTDC there is not enough fuel for the diffusion to takes place which results in poor diffusion and as a result the amount of fuel required to produce one kW of power is higher.

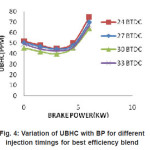

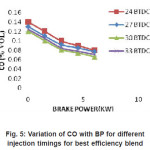

Comparison of the UBHC emissions for the four different injection timings for best efficiency blend (N20) is shown in Fig 4. Comparison of the carbon monoxide emissions for the four different injection timings for best efficiency blend (N20) is shown in fig no5. In both cases it can be seen that the UBHC and carbon monoxide emission is the highest in the case of the 24° BTDC and is least in the case of 30° BTDC.

Figure 3: Variation of SEC with BP for different injection timings for best efficiency blend

Figure 4: Variation of UBHC with BP for different injection timings for best efficiency blend

Figure 5: Variation of CO with BP for different injection timings for best efficiency blend

Oxides of Nitrogen & Carbon Di-Oxide

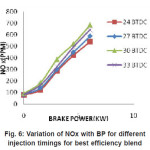

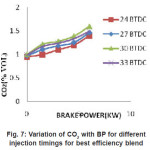

Comparison of the oxides of nitrogen emissions for the four different injection timings for best efficiency blend (N20) is shown in fig no.6. Comparison of the carbon di-oxide emissions for the four different injection timings for best efficiency blend (N20) is shown in fig no7. In both cases it can be seen that the oxides of nitrogen and carbon di-oxide emission is the highest in the case of the 30° BTDC and is least in the case of 24° BTDC. This is because at 30° BTDC the peak temperature in the combustion chamber increases due to the proper combustion which leads to increase in emissions. At 33° BTDC because of the advancement in injection timing, the peak pressure is lowered due to poor combustion. At 24° BTDC and 27° BTDC due to the poor combustion and spray characteristics, the oxygen content in the fuel is not fully burnt which results in lower emissions.

Figure 6: Variation of NOx with BP for different injection timings for best efficiency blend

Figure 7: Variation of CO2 with BP for different injection timings for best efficiency blend

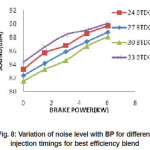

Sound Characteristics

Comparison of the sound characteristics for the four different injection timings for best efficiency blend (N20) is shown in fig no.8. It can be seen that the sound characteristics is the highest in the case of the 33° BTDC and is least in the case of 30° BTDC. This is because at 30° BTDC the proper combustion takes places and due to this the power developed helps in smooth running which results in lower noise level. At 24° BTDC and 27° BTDC due to improper combustion the noise level is marginally greater. At 33° BTDC due to higher amount of fuel accumulation in the combustion chamber initially, the engine tends to knock and this leads to increase in noise level.

Figure 8: Variation of noise level with BP for different injection timings for best efficiency blend

Combustion Analysis

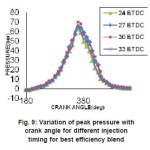

Peak Pressure Rise

Comparison of the peak pressure rise for the four different injection timings for best efficiency blend (N20) is shown in fig no.9. Peak pressure for pure diesel at 27°BTDC is 72 bar. Peak pressure of N20 for 30° BTDC is 70 bar, 33° BTDC is 67 bar, 27° BTDC is 66 bar and 24° BTDC is 63 bar. This is because complete usage of the fuel is observed at 30° BTDC which results in increase in the pressure as a result of proper combustion. At 33° BTDC due to increase in delay period, proper diffusion does not take place which results in lower pressure in the combustion chamber. At 24° BTDC and 27° BTDC due to a part of combustion taking place during the expansion stroke, the peak pressure drops.

Figure 9: Variation of peak pressure with crank angle for different injection timing for best efficiency blend

Comparison of the peak pressure rise for the four different injection timings for best efficiency blend (N20) is shown in fig no.9. Peak pressure for pure diesel at 27°BTDC is 72 bar. Peak pressure of N20 for 30° BTDC is 70 bar, 33° BTDC is 67 bar, 27° BTDC is 66 bar and 24° BTDC is 63 bar. This is because complete usage of the fuel is observed at 30° BTDC which results in increase in the pressure as a result of proper combustion. At 33° BTDC due to increase in delay period, proper diffusion does not take place which results in lower pressure in the combustion chamber. At 24° BTDC and 27° BTDC due to a part of combustion taking place during the expansion stroke, the peak pressure drops.

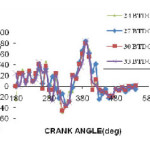

Instantaneous Heat Release Rate

Comparison of the instantaneous heat release rate for the four different injection timings for best efficiency blend (N20) is shown in fig no.10. Instantaneous Heat release rate for pure diesel is 88.65 J/deg CA at 27 deg BTDC. Heat release rate of N20 for 30° BTDC is 80.3 J/deg CA, 33° BTDC is 83.4 J/deg CA, 27° BTDC is 84.5 J/deg CA, and 24° BTDC is 86.12 J/deg CA.

Fig.10.Instantaneous heat release rate with crank angle for different injection timing for best efficiency blend. This is because at 30° BTDC, the increase in thermal efficiency indicates the complete burning of fuel and lower release of the heat to the exhaust and this reduces the instantaneous heat release rate. At 33° BTDC because of poor combustion the heat release rate is marginally higher. At 27° BTDC and 24° BTDC because of poor diffusion which causes the hot exhaust gases to escape out at a higher rate.

Scheme 1

Cumulative Heat Release Rate

Comparison of the cumulative heat release rate for the four different injection timings for best efficiency blend (N20) is shown in fig no.11. Cumulative heat release rate for pure diesel is 445.17 J/deg CA at 27deg BTDC. Cumulative heat release rate of N20 for 30° BTDC is 412.05 J/deg CA, 33° BTDC is J/deg CA, 27° BTDC is 428.27 J/ deg CA, and 24° BTDC is 433.62 J/deg CA. This is because at 30° BTDC due to proper combustion, the amount of heat released is lower as the heat is utilized to produce better efficiency resulting in lower cumulative heat release rate. At 33° BTDC the cumulative heat release rate is higher due to improper burning at different zones in the combustion chamber. At 27° BTDC and 24° BTDC because of poor combustion which takes place even after the expansion stroke commences which causes the cumulative heat release rate to rise higher.

Conclusion

From the above results and discussions, the following important points are observed and the effect of injection timing are listed,

Nerium oil, being non-edible oil proves to be a very effective alternate fuel.

After trans-esterification of Nerium oil, the kinematic viscosity and density is reduced while the calorific value is increased.

For Nerium oil, fuel injection at 30° BTDC results in approximately 2% rise in BTE when compared to 27° BTDC where as there is a fall of just 0.36% when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, SEC is found to be better by 3.02% when compared to 27° BTDC and just 1.207% lesser when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, UBHC emissions is found to be lower by 8.57% when compared to 27° BTDC and even lower by 13.51% when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, CO emissions is found to be lower by 0.011% when compared to 27° BTDC and even lower by 0.024% when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, Nox emissions is found to be higher by 16.2% when compared to 27° BTDC and even higher by 19.87% when compared to diesel at 27° BTDC .

For Nerium oil at 30° BTDC,CO2 emissions is found to be higher by 0.14% when compared to 27° BTDC and even higher by 0.35% when compared to diesel at 27° BTDC

For Nerium oil at 30° BTDC, Noise level is found to be lower by 0.90% when compared to 27° BTDC and higher by 3.16% when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, Pressure rise is found to be higher by 6.06% when compared to 27° BTDC and lower by 2.7% when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, Instantaneous heat release rate is found to be lower by 4.97% when compared to 27° BTDC and even lower by 9.41% when compared to diesel at 27° BTDC.

For Nerium oil at 30° BTDC, Cumulative heat release rate is found to be lower by 3.78% when compared to 27° BTDC and even lower by 7.43% when compared to diesel at 27° BTDC.

References

- A.K Babu and G. Devaradjane,”Vegitable Oil and Their Derivatives as Alternate Fuels for CI Engines an Overview”, SAE 2003-01-0767.

- O.J.Abayeh, E.C. Omuoha and I.A.Ugah,”TransesterifiedThevitaNerifolia Oil As A Bio-Diesel”, Global Journal Of Environmental Research 1(3): 124-127(2007).

- T Balusamy, R Marappan,”Performance Evaluation Of Direct Injection

- Diesel With Blends Of ThevitaPeruviana Seed Oil And Diesel”. J SciInd Res, 66: 1035-1040 (2007).

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal