Thickness Dependent Electrical Characterization of Electron Beam Evaporated N-Type Cdse Thin Films

S. R. Vishwakarma, Aneet Kumar Verma, Ravishankar Nath Tripathi and Rahul

Department of Physics and Electronics, Dr. R.M.L. Avadh University, Faizabad - 224 001 (India).

Corresponding Author E-mail: srvfzb@rediffmail.com

DOI : http://dx.doi.org/10.13005/msri/070222

Article Publishing History

Article Received on : 5 Oct 2010

Article Accepted on : 12 Nov 2010

Article Published : 01 Dec 2021

Plagiarism Check: Yes

Article Metrics

ABSTRACT:

The prepared starting materials has composition Cd0.60Se0.40 was used to fabrication of thin films. Cadmium selenide thin films of different thickness (400nm-700nm) deposited by electron beam evaporation technique on well cleaned glass substrate at substrate temperature 300 K. The X-ray diffraction pattern confirmed that the prepared thin films of composition Cd 0.60Se 0.40 has polycrystalline in nature. The resistivity, conductivity, Hall mobility, carrier concentration of the deposited films were calculated of different films thickness..

KEYWORDS:

n-type CdSe; resistivity; Hall mobility; Hall coefficient; carrier concentration

Copy the following to cite this article:

Vishwakarma S. R, Verma A. K, Tripathi R. N, Rahul. Thickness Dependent Electrical Characterization of Electron Beam Evaporated N-Type Cdse Thin Films. Mat.Sci.Res.India;7(2)

|

Copy the following to cite this URL:

Vishwakarma S. R, Verma A. K, Tripathi R. N, Rahul. Thickness Dependent Electrical Characterization of Electron Beam Evaporated N-Type Cdse Thin Films. Mat.Sci.Res.India;7(2). Available from: http://www.materialsciencejournal.org/?p=2432

|

Introduction

In resent year, there has been rapid development in the field of II-VI group ( CdSe, CdS, ZnSe, CdTe) semiconductor thin films owning to their wide range of applications. As an important member of this group of binary compounds cadmium selenide (CdSe) with a band gap of 1.7 eV of interest because of its optical and electrical properties for it applications as high efficiency thin film transistors1. Electrical and optical properties of semiconducting films are very sensitive to ambient condition and deposition technique used. Therefore study of such properties of the films with respect to their different growing as well as ambient conditions is a matter of profound importance2. In this paper some electrical properties of CdSe thin films studied under deposited by electron beam evaporation technique.

In the present works, cadmium and selenium in the original metallic powder form procured from Alfa Aesar Ltd. U.S.A. (Cadmium- 99.999% pure and Selenium 99.999% pure).

Experimental

Substrate Cleaning

The substrate

cleaning play an important role in the deposition of thin film, commercially

available glass slide with size of (75mm x 25mm x 1mm) washed using detergent,

chromic acid and finally washed with double distilled water in ultra sonic

cleaner and dry at 150o C in oven.

Deposition of Thin Films

The starting

material with composition of high purity cadmium (99.999%) and selenium

(99.999%) prepared by using

formula Cd0.60Se0.40 of

composition under dry powder reaction in vacuum 10-5 torr

below melting temperature. Films are deposited on glass substrate by electron beam evaporation using graphite crucible in

vacuum coating unit (Hind Hivac model -12A4) in vacuum(~

10-5 torr ).

Characterization of the CdSe Thin Films

The CdSe thin films were electrically characterized by four probe resistivity measurement setup designed by Scientific Equipment and Services-Roorkee (UK), Hall mobility measured using Hall setup designed by Scientific Equipment and Services-Roorkee (UK).

Table 1

|

S.No.

|

Composition

|

Film thickness

|

Hall coefficient ( m3/coulomb )

|

Carrier concentration

|

Hall mobility Resistivity at (cm2/volt sec) 300 K temp.

|

|

|

|

(per cm3)

|

at Room Temp.

|

(ohm-cm)

|

|

1 Cd0.60Se0.40 4 kÅ

|

43.428 × 10-6

|

1.439 × 1017

|

135

|

321.245×10-3

|

|

2 Cd0.60Se0.40 5 kÅ

|

28.397 × 10-6

|

2.200 × 1017

|

542

|

52.3164×10-3

|

|

3 Cd0.60Se0.40 6 kÅ

|

3.183 × 10-6

|

19.63 × 1017

|

574

|

5.5418×10-3

|

|

4 Cd0.60Se0.40 7 kÅ

|

3.163 × 10-6

|

19.75 × 1017

|

923

|

3.4265×10-3

|

Results and Discussion

The measurements of electrical resistivity and conductivity of the samples have been done by using a standard four probe method. This technique is widely used for the measurement electrical property of materials and has been proved to be a convenient tool for the resistivity measurement.

A four probe

measurement is performed by making four

electrical contacts to a sample surface.

Two of the probes are used as source current and remaining other two

probes are used to measure voltage. The advantage of the using probe is to

eliminate the occurrence of errors due to the probe

resistance, spreading resistance under and contact resistance between each metal probe and

material. The electrical resistivity ‘’ evaluated

by applying a direct

current ‘I’ through

the outer pair of probes

and measuring the voltage drop ‘V’ between the

inner pair of probes, which are positioned at a distance of S = 0.2 cm using the following equation-

= (2 II S/ G7 (w/s) )•(V/I)

Where,

G7 (w/s) = 2S/w

loge2

w = thickness of the

film, = resistivity.

From fig.1 to 4 confirms that the prepared film of various thickness are polycrystalline in nature.

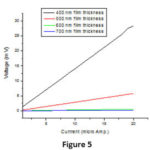

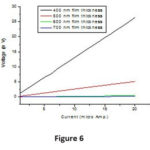

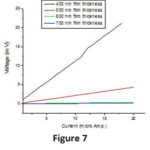

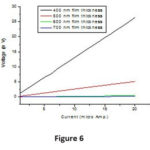

From figures 5 to 7 it is clear that resistivity decreases with increase the film thickness and confirmed that films are semi-conducting nature because the resistivity decreases as increase in temperature. Hall Effect measurement confirmed that films are of n-type. Table-1 shows that carrier concentration increase with increase the film thickness.

Hall coefficient (RH ) = (VH X w) / (Ix . Bz) Carrier

concentration (n) = 1/ ( RH . q ) Hall mobility (µH) = RH /

Where VH = Hall Voltage, Ix = Constant current in x- direction, Bz = Constant magnetic (400gauss) field in z- direction, = Resistivity of the film.

|

Figure 6

Click here to View figure |

Conclusions

In summary we concluded that the effect of films thickness on their electrical properties of the electron beam evaporated n-type CdSe thin films was investigated. The resistivity decrease from 321.245 × 10-3 to 3.4265 × 10-3 ohm-cm, charge concentration increases from 1.439 × 1017 to 19.75× 1017 per cm3 and also increases mobility from 135 to 923 cm2/volt sec with increases films thickness from 400 nm to 700 nm.

Acknowledgment

The authors wish to acknowledge the Department of Science and technology, government of India, New Delhi for providing financial support and also thanks for department of Nano Technology, Allahabad University, Allahabad for providing the facilities of XRD.

Conflict of Interest

There is no conflict of interest.

Funding Sources

There is no funding sources

References

- S.M. Hus and M. Parlak, Journal of Physics D. Appl. Phys. 41: 035405(8PP) (2008).

- K. Sarmah, R. Sarma, and H.L. Das, Journal of Physics Conference Series 114:

01204 (2008).

- K.D. Patel, R.K.

Shah, D.L. Mukhija, V.M. Pathak,

R. Srivastava- Journal of Ovonic research 4(6): 129-139 (2008).

- S.Erat, H. Metin, M. Ari- Material Chemistry and Physics 111: 114-120 (2008).

- O. Portillo-Moreno, R. Lozada-Morales, M. Rubin-Falfan, J.A. Parez-Alvarez, O. Zelaya-

Angel, L. Banos-Lopez , Journal

Phys. Chem. Solids 1751:

61 (2000).

- K. Bindu, M. Lakshmi , S. Bini, C. Sodha, Kartha, K.P. Vijaya, Kuma, T. Abe, Y. Kashiwada, Semi cond. Sci. Techol. 270: 17 (2002).

- T. Elango, S. Subramanian, R. K. Murali,

Surf. coat. Technol. 8: 123

(2003).

- N.J. Suthan, Kissinger, M. Jayachandran, K. Peramal

and C. Sanjeev Raja, Bull. Matter Sci. 30(6): 547-551 (2007).

Indian Academy of Science

- Ralf Erni, Nigel D.

Browing, Ultramicroscopy 107: 267-273 (2007).

- Sachin k. Sharma,Lakendra Kumar,

Sushil Kumar, T.P. Sharma

Chalcogenide letter 5(4): 73-78 (2008).

- D. Patidar, K.S. Rathore, N.S. Saxena, Kananbla Sharma, T.P. Sharma Chalcogenide letter 5(2): 21-25 (20

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal