M Karthikeyan1* , Dhanasekar K2

, Dhanasekar K2 , Theerkadharshini3, Aparna4

, Theerkadharshini3, Aparna4 and K Mohan Das5

and K Mohan Das5

1Department of Civil Engineering, Dhanalakshmi Srinivasan College of Engineering, Coimbatore Tamil Nadu, India.

2Department of Civil Engineering, Adi Shankara Institute of Engineering and Technology, Vidya bharati Nagar, Mattoor, Kaldy, Ernakulam ,Kerala India.

3Department of Civil Engineering, Saveetha Engineering College, Chennai. Tamil Nadu, India.

4Department of Civil Engineering, Sathyabhama University, Chennai, Tamil Nadu, India.

5Department of Civil Engineering, CMR College of Engineering and Technology, Hyderabad, Telangana, India.

Corresponding Author E-mail: mkartik2009@gmail.com

DOI : http://dx.doi.org/10.13005/msri/210103

Article Publishing History

Article Received on : 22 Dec 2023

Article Accepted on : 07 Feb 2024

Article Published : 13 Feb 2024

Plagiarism Check: Yes

Reviewed by: Dr. Abel Saka Second Review by: Dr. Alemayehu Getahun

Second Review by: Dr. Alemayehu Getahun Final Approval by: Dr. K. M. Garadkar

Final Approval by: Dr. K. M. Garadkar

Article Metrics

ABSTRACT:

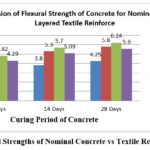

Through experimentation, the performance of textile-reinforced concrete (TRC) and conventional concrete as reinforcing materials will be compared in this study. In this work, essential strength characteristics are determined, and the influence of the polyester filament yarns on concrete mixes is investigated by including them in M30-grade concrete for nominal mix design. An essential component of optimizing concrete strength and durability is choosing the right curing time. The study's curing techniques focus on keeping the concrete from losing too much moisture. One of three approaches can be used to do this: either leave the form-work in place, cover the concrete with an impermeable membrane after the form-work is removed, use a water-based chemical curing agent, or combine these approaches. To reduce moisture loss, the exposed surface is continuously sprayed. Layers 1, 2, and 3 of the cloth must be organized in order to evaluate its split tensile, compressive, and flexural strengths. According to the experimental findings, the specimen that has two layers of textile in it achieves the best results in the split tensile, compression, and flexure tests. Nevertheless, the addition of three textile layers causes the strengths of compression and flexibility to diminish.

KEYWORDS:

Durability; Layer of fiber; M30 Grade; Membrane curing; Specimens; Strength; Textile fiber

Copy the following to cite this article:

Karthikeyan M, Dhanasekar K, Theerkadharshini T, Aparana A, Das K. M. Investigation into the Mechanisms Underlying the Behavior of Textile Reinforced Concrete. Mat. Sci. Res. India;21(1).

|

Copy the following to cite this URL:

Karthikeyan M, Dhanasekar K, Theerkadharshini T, Aparana A, Das K. M. Investigation into the Mechanisms Underlying the Behavior of Textile Reinforced Concrete. Mat. Sci. Res. India;21(1). Available from: https://bit.ly/3HZ3yOE

|

Introduction

Concrete stands out as one of the most versatile and predominant building materials due to its ability to be molded to fit various structural shapes. It is easily accessible in urban areas and is cost-effective. While concrete exhibits considerable strength under compression, it is relatively weak under tension. Concrete has many benefits, including great compressive strength, remarkable water resistance, superior fire resistance, low maintenance needs, and an extended service life.

However, there are certain drawbacks associated with the use of concrete. Notably, it has poor tensile strength, making it susceptible to cracking or failure when subjected to tension forces. Additionally, the construction process often necessitates formwork, adding complexity and cost to the overall project. Despite these limitations, the overall benefits of concrete, especially its robust compressive strength and durability, make it a preferred choice in a wide range of construction applications.

Concrete is inherently a relatively brittle material and lacks sufficient tensile strength. To enhance its tensile properties, reinforcement is incorporated into the concrete structure. The typical tensile strength of concrete hovers around 8% to 15% of its compressive strength. Over many decades, the challenge of concrete’s weakness under tension has been addressed through the implementation of a system involving reinforcing bars. This system, known as reinforced concrete, ensures that concrete primarily withstands compressive stresses, while steel bars bear the brunt of tensile and shear stresses.

Curing is controlling the temperature to control the cement’s rate of hydration. Only the moisture content needs to be checked if the concrete’s natural temperatures remain within an acceptable range during the curing process. Controlling the temperature of the concrete is necessary, though, if the ambient temperature rises above the allowable limit.

Objectives

Analyzing the properties of textile-reinforced concrete.

Investigating the impact of incorporating geotextile on the compressive and flexural strength of concrete.

Minimizing the need for reinforcement in reinforced concrete (R.C.C.).

Eliminating the reliance on water for the curing of concrete.

Enhancing the flexural strength of concrete.

Concrete

Cement, fine and coarse aggregates, and water in the right amounts make up concrete, a composite material. The aggregates are bound together into a solid mass by the chemical reaction of cement and water. Because fresh concrete is pliable, it may be compacted to form a dense mass and molded into any desired shape in the molds.

The transition of concrete from its pliable, plastic stage to a solid state is referred to as setting, and the subsequent development of strength after setting is termed hardening. Setting takes no more than 10 hours on average, and 90% of the hardening process is finished by the end of 28 days. The qualities of the components and the quality control procedures followed during the preparation and curing process have a major impact on the qualities of cement concrete as well as its overall attributes. As a result, it is crucial to carefully research the characteristics of each component of the concrete.

Cement

Cement plays a pivotal role in various construction applications, with its primary and crucial use being as a key component in the production of concrete. Concrete, formed by combining cement with aggregates, becomes a robust building material widely employed in construction projects. As a binder, cement is a substance utilized in construction that undergoes a process of setting and hardening, effectively binding and uniting other materials together to create durable structures.

Table 1: Properties of Portland Pozzolana Cement (Fly Ash based):

|

Particulars

|

Test Results

|

Requirements ofIS:1489-1991(Part1)

|

|

CHEMICAL REQUIREMENTS

|

|

Sl.No

|

Requirements

|

% in Mass

|

Limitations

|

|

1.

|

Insoluble Material

|

22.80

|

X+(4.0(100-X))/100

(x= declaration % of fly ash)

|

Max

|

|

2.

|

Magnesia

|

1.07

|

6.00

|

Max

|

|

3.

|

Sulphuric Anhydride

|

2.38

|

3.00

|

Max

|

|

4.

|

Loss on Ignition

|

1.72

|

5.00

|

Max

|

|

5.

|

Total Chlorides

|

0.035

|

0.10

|

Max

|

|

PHYSICAL REQUIREMENTS

|

|

6.

|

Fineness(m2/kg)

|

390

|

300

|

Min

|

|

7.

|

Standard Consistency (%)

|

33.5

|

|

|

|

8.

|

Setting Time(minutes)

|

|

|

|

|

a. Initial

b. Final

|

150

225

|

30

600

|

Min

Max

|

|

9.

|

Soundness

|

|

|

|

|

a. Le-Chat Expansion (mm)

b. Autoclave Expansion (%)

|

0.5

0.025

|

10.0

0.8

|

Max

Max

|

|

10.

|

Compressive Strength (MPa)

|

|

|

|

|

a. 72+/-1hr. (3days)

b. 168 +/- 2 hr. (7 days)

c. 672+/-4hr. (28days)

|

28.6

38.6

58.0

|

16

22

33

|

Min

Min

Min

|

|

11.

|

Drying Shrinkage (%)

|

UT

|

0.15

|

Max

|

|

12.

|

% of Fly Ash addition

|

25.0

|

15.0

|

Min

|

| |

|

|

35.0

|

Max

|

Sand

High-quality river bank sand is characterized by the absence of any earthy matter and organic content. The sand particles exhibit an almost angular shape, passing through a 250-micron standard sieve and retained on a 150-micron standard sieve. To ensure its purity, a sample is thoroughly washed in water to remove any earthy or organic impurities. Subsequently, the washed sample is dried over a 48-hour period in sunlight.

The desired properties of good river bank sand include being hard, durable, chemically inert, clean, and entirely free from organic matter. This ensures that the sand is suitable for various construction applications, contributing to the overall quality and performance of the materials used in building projects.

Table 2: Sieve Analysis Results

|

S.No

|

Sieve Size(mm)

|

Percent Retained

|

Cumulative % Retained

|

Percentage Passing

|

|

1

|

4.75

|

5.20

|

5.20

|

94.80

|

|

2

|

2.36

|

3.00

|

8.20

|

91.80

|

|

3

|

1.18

|

8.60

|

16.80

|

83.20

|

|

4

|

600microns

|

25.80

|

42.60

|

57.40

|

|

5

|

300microns

|

32.80

|

75.40

|

24.60

|

|

6

|

150microns

|

20.70

|

96.10

|

3.90

|

Table 3: Properties of Fine Aggregate.

|

S.No

|

property

|

Result

|

|

1

|

Specific Gravity

|

2.6

|

|

2

|

Finesses modulus

|

2.8

|

|

3

|

Bulk Density

|

15.75kN/m3

|

|

4

|

Grading of sand

|

Zone-II

|

Coarse Aggregate

Crushed granite stone chips of maximum sizes 1” and 1/2” available in the local quarries were obtained. The aggregate of 1” size was sieved to separate the chips of size greater than 20mm. The remaining aggregate and aggregate of 1/2” size were mixed in the ratio of 20 : 80 respectively to get 20mm minimum size graded aggregate satisfying the specifications of IS : 383-1970

Geotextile

‘Geotextile’ can be separated into two terms, ‘geo’ and ‘textile’. The word ‘geo’ comes from the Greek meaning ‘earth’, so geotextiles can be defined as the permeable textile materials that are used in combination with soil or any other civil engineering material. Geo textile is a branch of technical textiles. Geotextile is a special type of polymer fabric (polyester, polypropylene etc.) with very small holes that is used to improve the soil properties in civil construction projects. Geotextile is an ideal textile material for roads, ports, landfills, breakwater construction, drainage structures and other civil projects. According to The Textile Institute, “permeable textile material used for filtration, drainage, separation, reinforcement and stabilization purposes as an integral part of civil engineering structures of earth, rock or other constructional materials”.

Table 4: Physical Properties Geotexitle

|

S.No

|

Properties

|

Geotextiles

|

Strong biaxial geogrid

|

|

1

|

Apertures Size (mm)

|

–

|

30×30

|

|

2

|

Ulitimate tensile strength (kN/m)

|

55.16

|

38.1

|

|

3

|

Yield strain(%)

|

38

|

16.7

|

|

4

|

Secant modulus at 2% strain (Kn/m)

|

151

|

588

|

|

5

|

Mass per unit area strain( kN/m)

|

230

|

530

|

Membrane Curing

Membrane curing is an advanced and specialized curing method that involves the use of ROOFEX CURE WB. This particular approach is recommended in situations where a transparent coating is needed, providing an effective and specialized solution for curing processes. Curing membranes must be specified to cure concrete having a w/c greater than 0.42 made with either Portland cement or blended cement. When concrete is cast in dry and moderately windy conditions, usually the bleeding water that covers the finished concrete surface protects the concrete from plastic shrinkage long enough to have time to apply a curing membrane at a dosage (L/m2) recommended by admixture companies. It is only when air is particularly dry and/or particularly windy that fogging is recommended before applying curing membranes.

Features and Benefits

Easy and Safe Spray Application: The product is non-toxic and non-flammable, allowing for a convenient and safe spray application process.

Drying Time: Rapid drying, typically less than one hour, ensuring efficiency in the curing process.

Acrylic Blended, White Pigmented Curing Membrane: Provides a white-pigmented curing membrane for new concrete, offering compatibility with many paints, adhesives, and resilient floor coverings.

Methodology

The below is the flow chart of Research Methodology adopted for this project.

Literature Collection

Literature from different journals has been collected and research gap has found.

Objective: Research gap has been identified and a objective has initiated which should be helpful for society.

Study on material property: All the materials required for the project are procured and their basic properties are found.

Mix Design: As per IS standards mix design is prepared for standard concrete.

Tests on fresh concrete: Some of the tests for plastic concrete are done at Laboratory.

Casting and Curing: Batching & mixing is done as per mix design and casted test specimen. After casting the specimen they are cured in water for 7 days, 14 days and 28 days.

Tests on Hardened Concrete: Specimen is tested for Compressive Strength and Flexural strength on 7th ,14th and 28th day after casting

Results Comparison and Conclusion: Testing results are been compared with each other and a brief analysis is made to give a conclusion

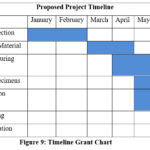

Timeline of the Project

Mix Proportion

Table 5: Mix proportion for concrete

|

Material

|

Quantity (kg/m³)

|

|

Cement

|

350

|

|

Water

|

140

|

|

Chemical Admixture

|

7

|

|

Fine Aggregates

|

830.56

|

|

Coarse Aggregate

|

1215.43

|

|

W/C Ratio

|

0.4

|

Results and Discussion

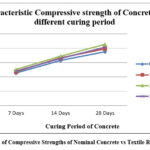

Compressive Test of Concrete

Table 6: Average of 3 cubes of Nominal concrete for 28 days

|

S.No.

|

Days

|

Load

(KN)

|

Characteristic Compressive Strength

(N/mm2)

|

Cross sectional Area(mm2)

|

Average Compressive

Strength(N/mm2)

|

|

1

|

28

|

826.2

|

36.72

|

150*150mm

|

37.48 N/mm2

|

|

2

|

857.25

|

38.1

|

|

3

|

846.45

|

37.62

|

It appears from the above table that the average compressive strength of nominal concrete, as determined from three cubes tested at 28 days, is 37.48 N/mm².

Table 7: Average of 3 Beams of two layers Textile Reinforced concrete for 28days.

|

S.No.

|

Days

|

Load

(KN)

|

Flexural Strength

(N/mm2)

|

Length(mm)

|

Cross sectional Area

(mm2)

|

Average flexural Strength

(N/mm2)

|

|

1

|

28

|

11.72

|

5.86

|

500mm

|

100*100

mm

|

6.24N/mm2

|

|

2

|

12.92

|

6.46

|

|

3

|

12.8

|

6.4

|

It is observed from the above table that the average flexural strength of concrete with two layers of textile reinforcement, based on tests conducted on three beams at 28 days, is 6.24 N/mm².It is 42% greater than the conventional beam.

Conclusions

The previously described results were obtained after our theoretical ideas were put into practice. Based on the results the project was able to achieve, the following conclusions have been drawn:

It was previously shown that adding two layers of geo textile—one on top and one at the bottom 42% increase the flexural strength of concrete beam compares to normal beam.

It should be noted that the compressive strengths of the two types of concrete are identical.

In addition, membrane curing has replaced conventional pond curing. In the end, the curing procedure required very little water—in fact, it used less water overall.

In addition, the flexural strength variation shows that the flexural strength is approximately 48% greater than the nominal concrete.

By incorporating a double layer at the top and a single layer at the bottom of the geotextile material into the concrete beam, we can partially lower the reinforcement material based on the results of the flexural strength test.

When examining the split tensile strength variance, there is also an increase of around 46% in split tensile strength compared to the nominal concrete.

Acknowledgement

The author would like to express their gratitude towards, Dhanalakshmi Srinivasan College of Engineering, , Coimbatore Tamilnadu, India. For providing the necessary infrastructure to carry out this work successfully.

Author Contribution

Author SF is involved in data collection, experimental study and manuscript writing. Author LP and MS was involved in conceptualization, guidance and critical review of the manuscript.

Conflicts of interest

No conflict of interest in this manuscript.

Funding Sources

We thank the following organizations for providing financial support that enables us to Complete the study.

REFERENCES

- Jalagadugula, V., Ganesan, P., & Rao, S. (2019, November 01). Review of textile reinforced concrete. https://ijsrd.com/Article.php?manuscript=IJSRDV6I110146

- C.N. Gayathri, R. Baby Singh, Dr. G. Dhanalakshmi (2018), “Mechanical Behaviour Of Textile Reinforced Concrete”, International Research Journal of Engineering and Technology (IRJET), Volume: 05 Issue: 05, May-2018, e-ISSN: 2395-0056

- Chand Mukund (2018), “Review paper on the Textile Reinforcement concrete (TRC)”, International Journal of Advance Research in Science and Engineering (IJARSE). Volume No. 07, Special Issue No. 01, April 2018.

- Ankita V.Kalbande, Anand G.Chavan, Feroz H. Khan(2017) “Experimental Strength Analysis of Membrane Curing Methods Using Polythene Sheets of Different Colors”, International Journal of Innovations in Engineering and Science,Issue Vol. 2, No.1, 2017.

- Gopinath, S., Ramachandra Murthy, A., Iyer, N. R., & Dharinee, R. (2016).” Investigations on textile-reinforced concrete as cover for RC beams”. Magazine of Concrete Research, 68(20), 1040–1050. doi:10.1680/jmacr.15.00161

CrossRef - K Mohan Das, Ms Ganagam Saileela, Mr,Nelakuri Manoj Kumar, Improve TheShear Strength Of Soil By Using Micro-Piles As Foundation, Dogo RangsangResearch Journal UGC Care Group I,Journal ISSN : 2347-7180 Vol-12 Issue-08,No. 04 August 2022.

- T Ananth, Mr Prasoon PP, Mr CVijayakumar, K Mohan Das, PartialReplacement Of cement With Sugar CaneBagasse Ash And Hybrid Fibers ,DogoRangsang Research Journal UGC CareGroup I Journal ISSN : 2347-7180 Vol-12Issue-08 No. 04 August 2022.

- Rameshwari S, Mr. P. Thangamuthu, P. Karthik, A.Sathiyamoorthy,V.Yogeshwaran, PG Student, Dr.K.MohanDas, P “AN EXPERIMENTAL STUDYON SLICA FUME CONCRETE WITHADDITION OF FIBRES”, DogoRangsang Research Journal UGC CareGroup I Journal ISSN : 2347-7180, Vol-12Issue-11 No. 03 November 2022

- Bommena Karthik, E Rani, MSVKVPrasad, Mr K Shanthakumar, K MohanDas,” SEISMIC ANALYSIS OF AMULTISTORIED RC STRUCTUREWITH AND WITHOUT LEAD PLUGRUBBER BEARING ( LPRB )” DogoRangsang Research Journal UGC CareGroup I Journal ISSN : 2347-718, Vol-12Issue-08 No. 06 August 2022

- K Mohan Das, Ms Ganagam Saileela, MrNelakuri Manoj Kumar “IMPROVE THE

- Shear Strength Of Soil Byusing Micro- Piles Asfoundation” Dogo RangsangResearch Journal UGC Care Group IJournal ISSN : 2347-718, Vol-12 Issue-08No. 04 August 2022.

- Dr. K. Mohan Das Mr.Prasoon PP, Dr.M.Siva A, Dr. A.Hemalatha, K.Shanthakumar, “ANALYSIS OF M60 Grade Concrete Using Silico-Manganese Slag As The Partialreplacement Of Coarse Andfine Aggregates”, Dogo RangsangResearch Journal UGC Care Group IJournal ISSN : 2347-718, Vol-12 Issue-08No. 04 August 2022.

- Gaddam sagar , V. Srinivas , K. MohanDas, “A Study of the Effect of Inhibitorson Rebar Corrosion in Concrete and theLife of Rebar Cement” Emperor Journal ofApplied Scientific Research ISSN No.2581-964X(O) Vol. 4 Issue–10 October

- M.Amala A.Meenachi A. Gopalan P.M.B. Raj Kiran Nanduri d, K. Ramesh , K. Mohan das ”AN EXPERIMENTAL INVESTIGATION OF M30 GRADE SELF COMPACTING CONCRETE USING SUPPLEMENTARY CEMENTITIOUS MATERIALS” Material today proceedings ,1 June 2023.

CrossRef - GHARSHITH CHOWDARY, A SRIHARSH, ANALYSIS AND DESIGN OF COMMUNICATION TOWER USING ETABS”International Journal For Recent Development In Science And Technology”

Views: 1,014

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

, Dhanasekar K2

, Dhanasekar K2 , Theerkadharshini3, Aparna4

, Theerkadharshini3, Aparna4 and K Mohan Das5

and K Mohan Das5

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal