Abdul Raheem1* and K.M. Subbaya2

and K.M. Subbaya2

1Department of Mechanical Engineering, Brindavan College of Engineering, Bangalore-560063, VTU, Karnataka, India.

2Department of Industrial and Production Engineering,The National Institute of Engineering, Mysore 570008, VTU, Karnataka, India.

Corresponding Author E-mail: abdulraheem3030@gmail.com

DOI : http://dx.doi.org/10.13005/msri/180101

Article Publishing History

Article Received on : 12-Dec-2020

Article Accepted on : 27-jan-2021

Article Published : 01 Feb 2021

Plagiarism Check: Yes

Reviewed by: Dr. Murugesh V

Second Review by: Dr. Guru Swamy

Final Approval by: Dr Satyabrata Jit

Article Metrics

ABSTRACT:

Parts and constructions performance in the marine environments are subjected to high stress a priori to the measures of wind and waves. This review involve about the hybrid composite fabrication from artificial fibers of polymer composite. Hybrid composite furnish combination of property such as tensile modulus, compressive and impact strength which cannot realized in composite materials. The materials used for marine propellers of a varying number of blades with the fixed and controllable pitch having different diameters and skew angles and type of propellers were reviewed. Structural simulation, erosion wear tests, cavitations, bend twist coupling analyses, CFD case studies, fluid simulation method reviewed in this paper.

Glass fiber composites proved to be economical and its adaptable in economical point of view. Carbon fiber composite propellers have more advantages than others with little compromise. In current scenario hybrid composite have been established as highly efficient, structural materials, high performances and their use is rapidly increasing. The current paper outline the utilizing of hybrid composite material for marine propellers as their versatility in enhancing good results.

Copy the following to cite this article:

Raheem A, Subbaya K. M. A Review on Hybrid Composites used for Marine Propellers. Mat. Sci. Res. India;18(1).

|

Copy the following to cite this URL:

Raheem A, Subbaya K. M. A Review on Hybrid Composites used for Marine Propellers. Mat. Sci. Res. India;18(1). Available from: https://bit.ly/3j7Nqx2

|

Introduction

Thermoset polymer Composites are important class of engineering materials used in modern day engineering applications. Advanced fast growing technology is composite technology in present scenario and replacing metal by its less weight. Composite materials characteristics to attain a particular objective, which guide to superior performance compare to other regular alloy materials. Hybrid composites is choice. The propeller is the critical part of the ship. stability, durability and costs play is important role in the propeller selection. Conventionally propellers are made with steels, aluminium ,cast iron and some alloys. Advanced Hybrid composites used for academic researchers, industry and also offers field an opportunity to create innovative ideas explore for new generation. From last few decades as the whole world used hybrid composite material because of their its strength, high stiffness, long life, and low cost. its focus on marine research and provides composite material of various ship parts such as hull, deck, drive shaft, mast and propeller. Research interest on alternative materials for the propeller is increasing day by day; new materials was introduced in research. The recent studies carried out on composite propeller as shown in figure 1 was evident in introducing new materials [1]. Though composite materials manufactured by many processes are available, many researchers had fabricated composites by vacuum bagging process[2], VARTM process[4],and hand layup process[9] and tested their effectiveness. Studies were extended on composite material to determine and optimize the operational characteristics[5,6,7], Cavitation response[3], natural frequencies[9], Finite element methods[12]. we could take advantage of composite materials and characteristics to achieve a specific goal, which could lead to better performance than using alloy materials. The ambiguity that which composite is more suitable and again if it is preferable hybrid composite leads in withholding the load, propeller types, operating speed and torque requirements. Among numerous verities of propellers and composite material suggested by researchers globally were reviewed in this paper for emphasizing them for future applications.

Figure 1: The recent studies carried out on composite propeller

Application areas of Hybrid Composite material

In Beams

In Beams Hybrid composites are used in Construction beams, Hybrid beams consisting of consolidation of fiber reinforced polymer with steel and concrete. The hybrid composite beams are forceful, stiffness, lightweight and corrosion resistant. These beams are very effective, low cost than the orthodox structural members. Hybrid composite have more Safety and excellent strength than the standard and it gives a minimum maintenance of structure. Hybrid composite is much stronger than steel and concrete.

Figure 2: Hybrid composite beam constructed railroad bridge. TTCI – Pueblo, CO 9.1m (30 ft).

In Structural

In Structural Hybrid composites are used in Construction structures, they use of least material resources, increase the life span of buildings, very low environmental impact and ensure the high quality of civil infrastructures. specified design requirements used in hybrid composites a more cost-effective than traditional. Hybrid composites provides much more facilities than traditional composites including strength, stiffness, bending ,improved impact resistance, improved fracture toughness, reduced weight and low cost.

Figure 3: Hybrid Composite Structure

In Telecom

In Telecom Hybrid composites are used in telecommunication industry, Hybrid composite cable used in everyday, its support for power transmission if telecom is on. In orthodox quad cable is used for communication and signal purpose in railway, Now technology has developed to increase in application of communication for optical fiber cable and data transmission are connecter. This cable also helpful to power the remote equipment from the station generator. Railways provide lower cost of service to passengers. Hybrid cable design which reduces not only cost of installation but also total cost.

Figure 4: Hybrid Composite in cabling system

In Aerospace

In Aerospace Hybrid composite material which provides more strength to weight ratio than metals. Aircraft components made up of hybrid composite material. The design of aircraft parts to meet the various criteria of safety and power. It played an important role in weight reduction, they reinforcements such as carbon, glass fibers reinforced epoxy. Carbon fiber is most widely used in aerospace application. Fiber reinforced epoxy composite have been recycled of aircraft engine to intensify the achievement of the system. Hybrid composite material can make pilot cabin door and transport system. The application of glass fiber-epoxy composite ranging from printed circuit boards to shotgun barrels.

Figure 5: Hybrid Composite Used in Aerospace application

In Wind Energy

In Wind energy The wind power is greater importance in the area of energy generation due to its ecologically safe, its resource saving. In current hybrid fibers such as glass, carbon are mainly used in turbine blade fabrication. Manufacturing of turbine blades an application hybrid composites is suggested on the basis of epoxy matrix. Its gives high strength and high modulus compared to conventional methods.

Figure 6: Hybrid Composite Used in Wind energy applications.

In Marine

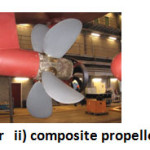

In Marine Hybrid composite materials are used nowadays extensively in the construction of ships and marine structures since composites have a higher strength and stiffness to weight than compare to most other materials like steel and aluminium. Boat hulls, ship structure, minesweepers, and propeller are fabricated by composite material.

Figure 7: i) 4 bladed propeller ii) composite propeller iii) Fixed Pitch Propeller

Literature Review

Gourav Gupta et al.,[1] give a review on application and future of composite materials. This paper presents a review of composite material have wide advantages and applications in various field. Author concluded that application of composite material are used in domestic purpose like furniture, window, marine, chemical industries, civil structures, various parts of aerospace, automobile, leaf spring, curved fairing and fillets, tubes, cylinders, ducts, medical devices, sports goods etc. V. Fiore et al.,[2] studied of unidirectional basalt fiber layers on the mechanical performance in E-glass short fiber reinforced epoxy hybrid composite for marine applications. Composite laminates fabricated by the vacuum bagging technique. Three point bending and Highest tensile strength in hybrid laminates compared to GFRP laminates due to the presence two external layers of basalt fibers in hybrid laminates.

Tadashi Taketani et al.[3] studied the performance of a ship five-bladed propellers aluminium, dry carbon, and nylon powdered composites with skew angle 200. Model test is performed in cavitations tunnel. For small deformation simulations results showed good agreement with experimental results and also consistent, For large deformation simulations results are inaccurate. S.Castegnaro et al.[4] studied the 4.6 m flax-epoxy and wood racing sailboat. from the materials selection, to design, manufacturing method, sailing and develop a bio-composite craft. fabrication was done by VARTM technique. showed typical scatter of natural components. Tensile test conducted on three specimens and to ensure minimum repeatability. Resin absorption test were performed. a specific multi-step inclusion technique wasdeveloped to manufacture of hull, deck. the boat final weight to 65 kg. The sailboat performance is good. L.Calabrese et al.[5] studied the flax and glass fiber combined reinforced epoxy hybrid composite. The flexural and dynamic mechanical analysis were performed. Hybrid composites exhibits both flexural strength by 90% and modulus by 128% due to the presence of glass fiber on flax laminates. D.Harsha Vardhan et al.[6] give a review on different materials used in marine propellers. In this paper we have understand it composite material review used for marine propellers of a varying number of blades with the fixed and controllable pitch having different diameters and skew angles and type of propeller. Dipak Kumar Jesthi et al.[7] has reported that the influence of carbon and glass fiber in the hybrid composites on seawater absorption. The results shows that the highest tensile strength of hybrid composite[GCG2C]s was achieved by 14% as compared to plain GFRPC and CFRPC. The flexural strength and modulus in [GCG2C]s hybrid composite is 43% and 64% respectively. Manjunath pattan et al.[8] studied the influence of jute and aramid fiber reinforced epoxy resin of hybrid composite. The fabrication was done by hand lay-up technique. The results indicate that hybrid composites exhibits excellent mechanical behaviour. Rao et al.[9] studied harmonic analysis on S-glass fiber composite four bladed propeller compared with an aluminium propeller. It has observed S-glass fiber composite was safe against resonance and also glass fiber composite propeller has more damping effect which reduces the vibration levels. Hong et al.[10] studied the influence of CFRP composite material have five bladed propellers with four different skew angles of 00,360,720,1080 at the propeller tip respectively. B.G.Patik et al.[11] Investigated acoustic response and performance characterization with PIV on glass-epoxy and carbon-epoxy propeller. It was found that glass-epoxy propeller shows better acoustic performance than the carbon-epoxy and in the cost point of view. Pavan Kishore et al.[12] Performed modal analysis on 4 bladed R-glass, S-glass, UD carbon/epoxy composite. It has observed that from FEA simulation, the natural frequency of metallic propeller was 22% higher than composite propeller.

Conclusion

Hybrid composites used for academic researchers, industry and also offers field an opportunity to create innovative ideas explore for new generation. The whole world used hybrid composite material because of their its strength, high stiffness, long life, and low cost. its focus on marine research and provides composite material of various marine propeller. Materials and type of propeller were different from researcher to researcher. Regarding number of blades, skew angles, and propeller series studied by researchers may be according to their local suitability and demand they have studied on different propellers. The material point of view ,many researchers used carbon or graphite base fiber composite propeller as it has proven. Even glass fiber polymer composites have exhibited winning performance in a few conditions; due to density difference between carbon and glass, carbon fiber is preferable. In the cost point of view carbon fiber is more expensive than the glass fiber. To balance cost with the performance of hybrid composite can be suitable for marine propeller. A couple of studies proved that hybrids were best. However extensive studies are to be carried in the area of application of hybrid composite materials for the marine propeller to enhance its efficiency, life, torque transmitting capability and cost efficiency. There is broad scope for the future study of the marine propeller with hybrid composites.

Acknowledgement

Authors would like to thank our Research guide for their continuous support and encouragement.

Funding sourse

No funding was received to carry out the research work presented in this research paper.

Conflict of Interest

The author declares that they have no conflict of interest.

References

- Gourav Gupta, Ankurkumar, Rahul tyagi, Sachinkumar, “Application and Future of Composite Materials: A Review “, International Journal of Innovative Research in Science, Engineering Technology(IJIRSET) ISSN:2347-6710,Volume- 5, Issue-5, May-2016

- V.Fiore, G.Di Bella, A.Valenza ,”Glass-basalt/epoxy hybrid composites for marine applications”, Materials and Design 32(2011) 2091-2099.

CrossRef

- Tadashi Taketani, Koyu Kimura, Satoko Ando, KoutakaYamamoto.”Study on Performance of a Ship Propeller Using a Composite Material”,May 2013.

- S.Castegnaro, C.Gomiero, C.Battisti, M.Poli, M.Basile, P.Barucco, U.Pizzarello, ” A bio-composite racing sailboat: Materials selection, design, manufacturing and sailing”, Ocean Engineering 133(2017)142-150.

CrossRef

- L.Calabrese, V.Fiore, T.Scalici, A.Valenza, ,”Experimental assessment of the improved properties aging of flax/glass hybrid composite laminates for marine applications”, Journal of Applied Polymer Science,DOI:10.1002/APP.47203, 9 September-2018.

CrossRef

- D.HarshaVardhan, A.Ramesh, B.Chandra Mohan Reddy,”A Review On Materials Used For Marine Propellers”,Materials Today: Proceedings 18(2019) 4482-4490.

CrossRef

- Dipak Kumar Jesthi, Ramesh Kumar Nayak, “Improvement of mechanical properties of hybrid composites through interply rearrangement of glass and carbon woven fabrics for marine application”, Composite Part B 1689(2019) 467-475. 8.

CrossRef

- ManjunathPattan, SudarshanShetty, Bipin J, Sajjan S.C, “Experimental Study on Mechanical Properties of Hybrid Composite Material “, International journal of Engineering Research & Technology(IJERT)ISSN:2278-0181,Volume- 7, Issue-7, 2019.

- Rao.Y.S, Reddy BS, Harmonic analysis of composite propeller for marine applications. Int J Res Engg Technol 2012;257-260.

CrossRef

- Hong Y,Wilson PA. Numerical analysis and Performance comparison of the same series of composite propellers. Ocean Engg.2017; 144;211-223.

CrossRef

- B.G.Patik, Kim G Do, Kim KY. Investigation on the performance characteristics of the flexible propellers. Ocean Engg 2013;73;139-148.

CrossRef

- Pavan Kishore. Free vibration analysis of four parameter. Proc 4th SARC Int Conf 2014;36;88-91.

Views: 1,786

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License.

and K.M. Subbaya2

and K.M. Subbaya2

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal